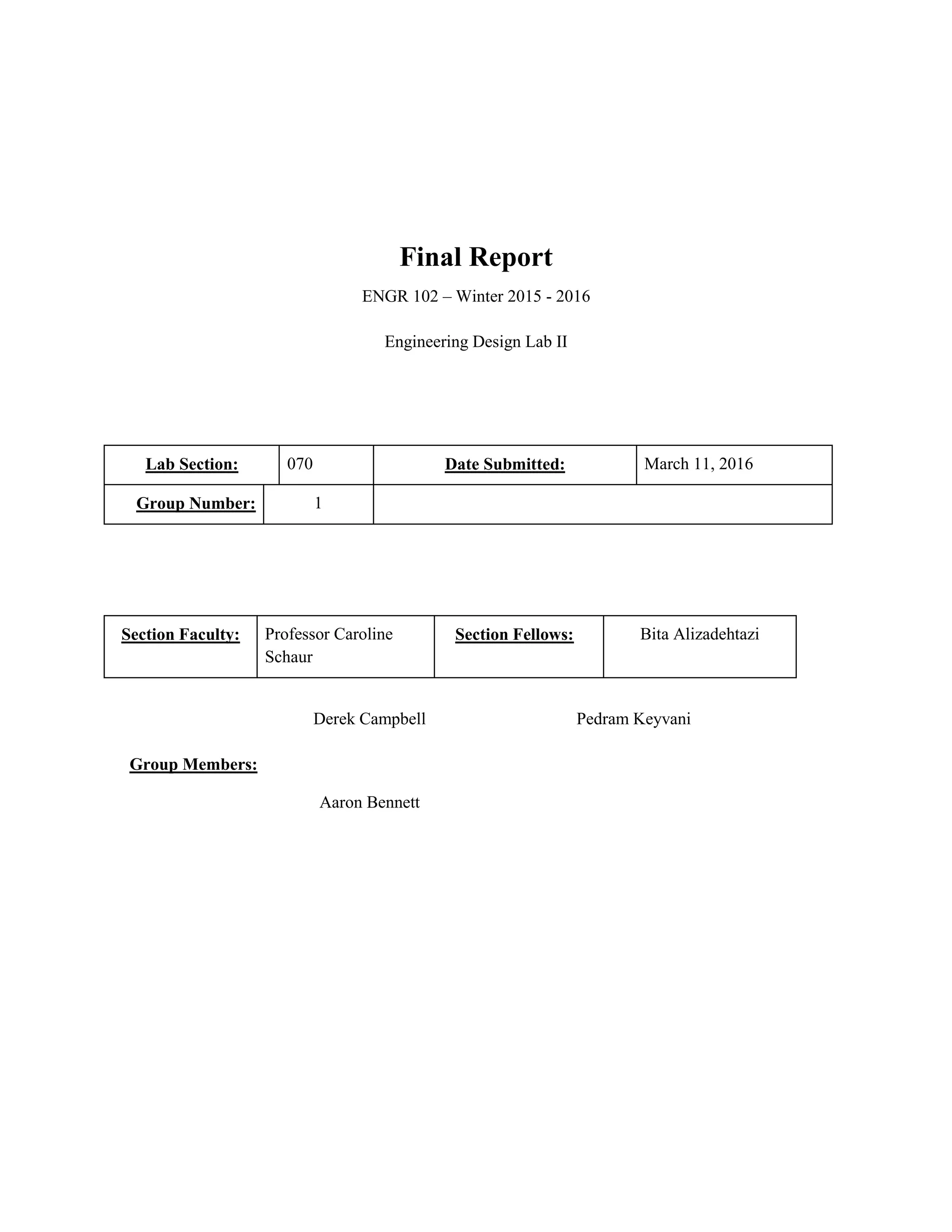

Group 1 designed and built a robot to collect nuclear waste scattered across land. They went through many iterations of the robot's design and code to overcome challenges. In the preliminary competition, the robot was damaged and performed poorly. However, Group 1 learned from their mistakes and made significant improvements to the robot's physical design and programming. They are optimistic about achieving better results in the final competition due to their lessons learned and hard work.