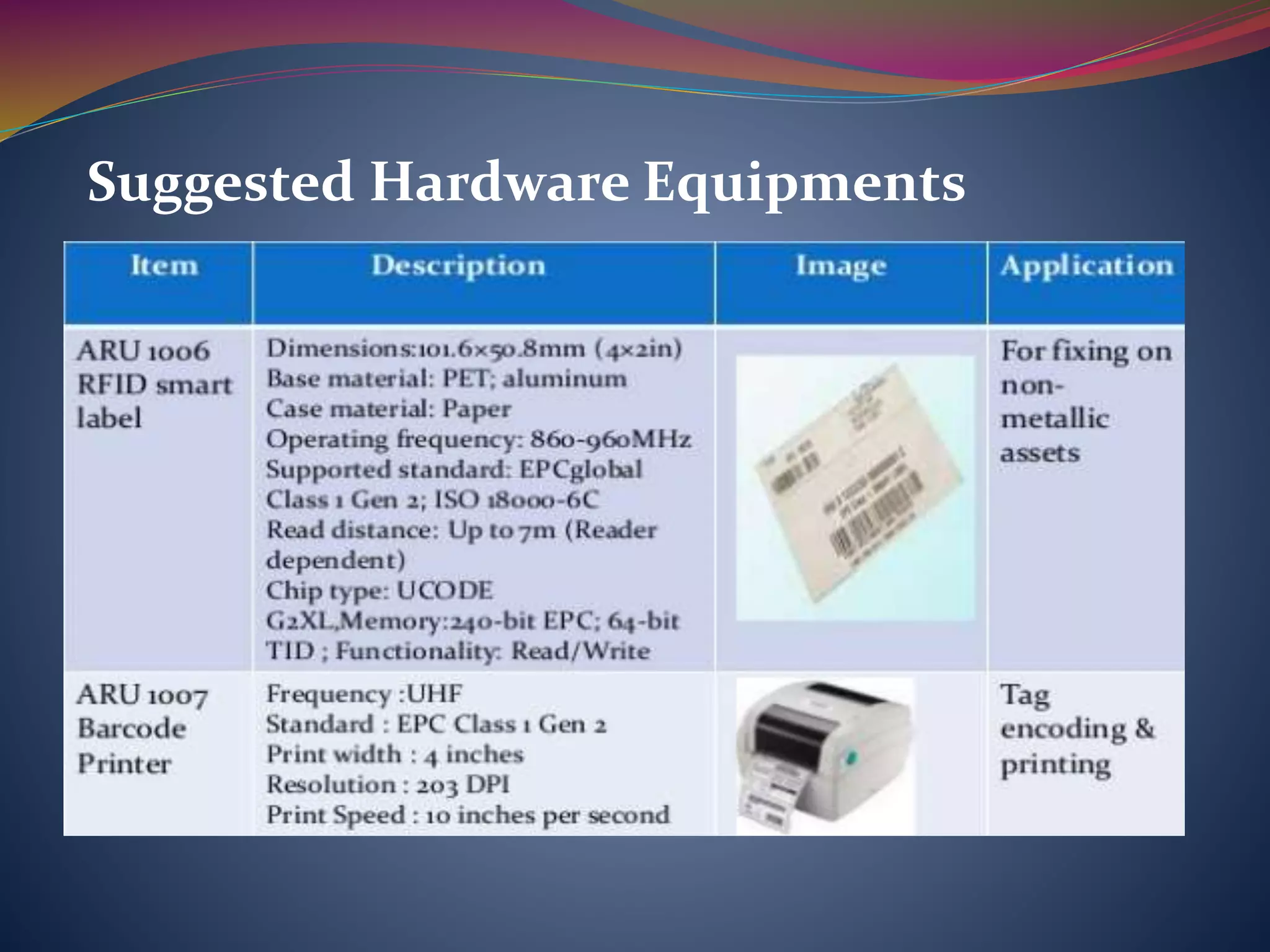

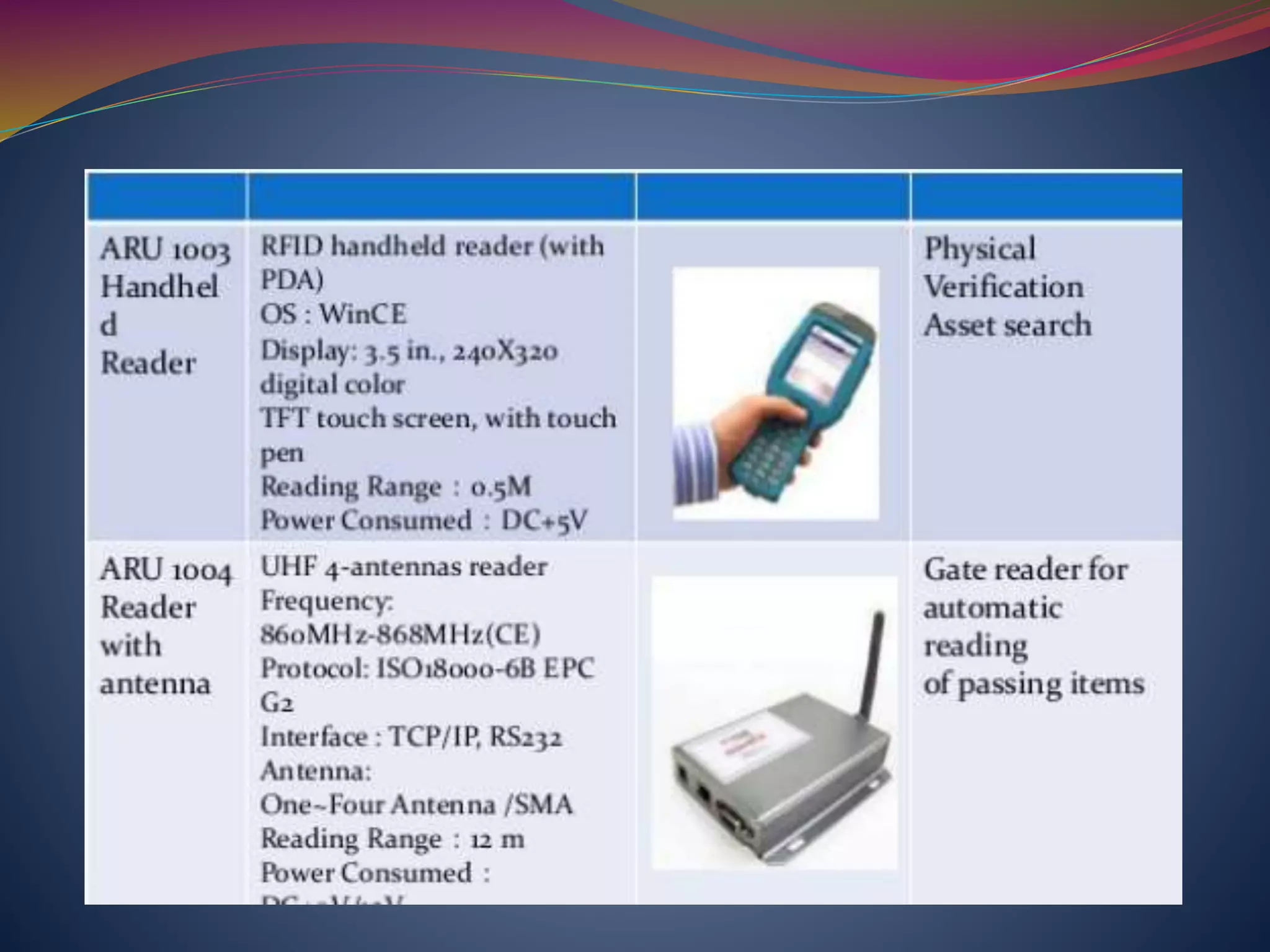

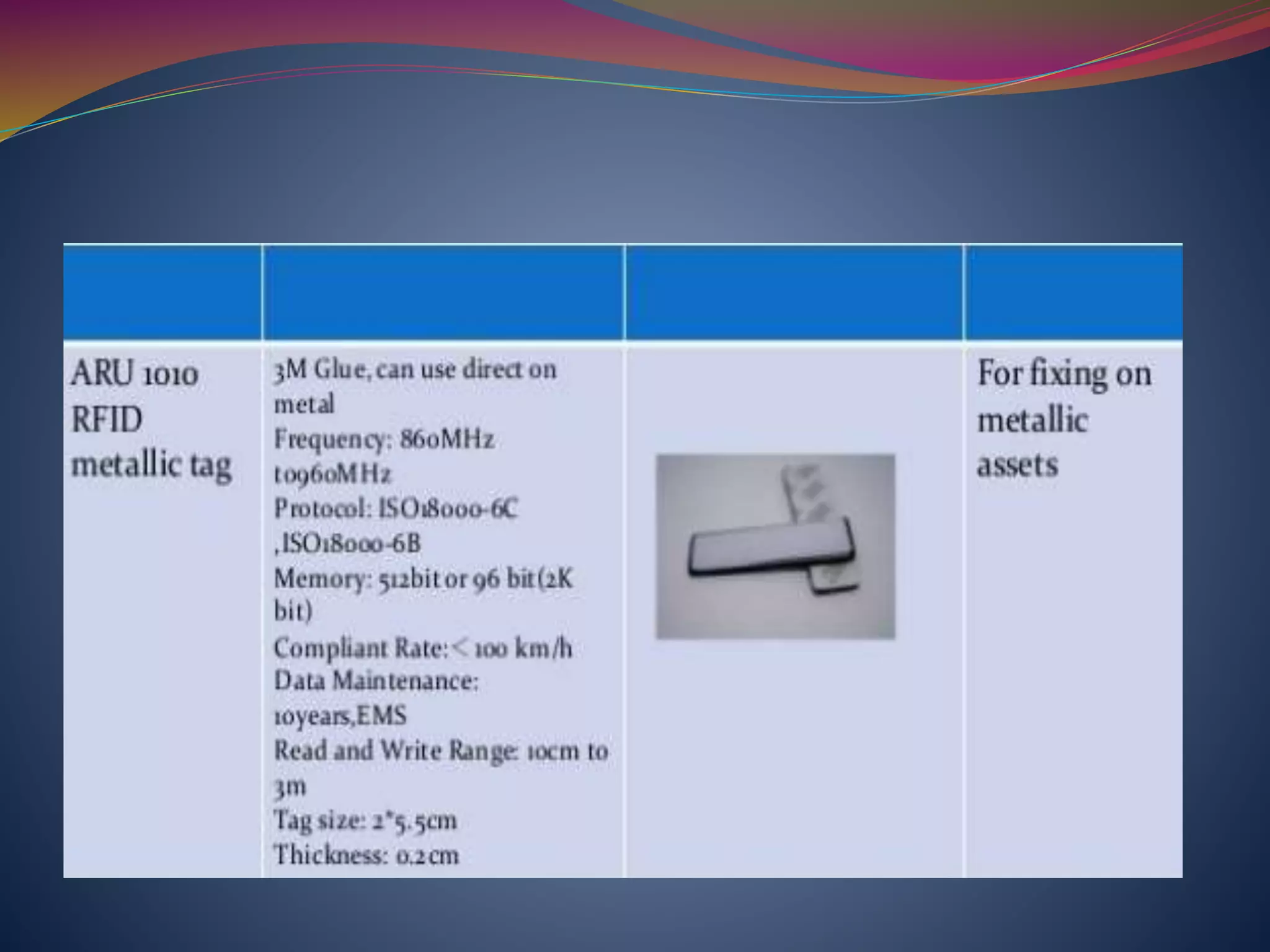

This document discusses an RFID-based asset management solution. It describes how RFID tags can be used to track assets by giving each one a unique ID encoded on the tag. A mobile RFID reader can then read tag IDs and locate assets or track their movement between locations. Key benefits include accurate real-time tracking of asset locations and information without manual data entry, improving efficiency. Suggested hardware includes RFID tags, readers, and encoders to implement this automated asset management system.