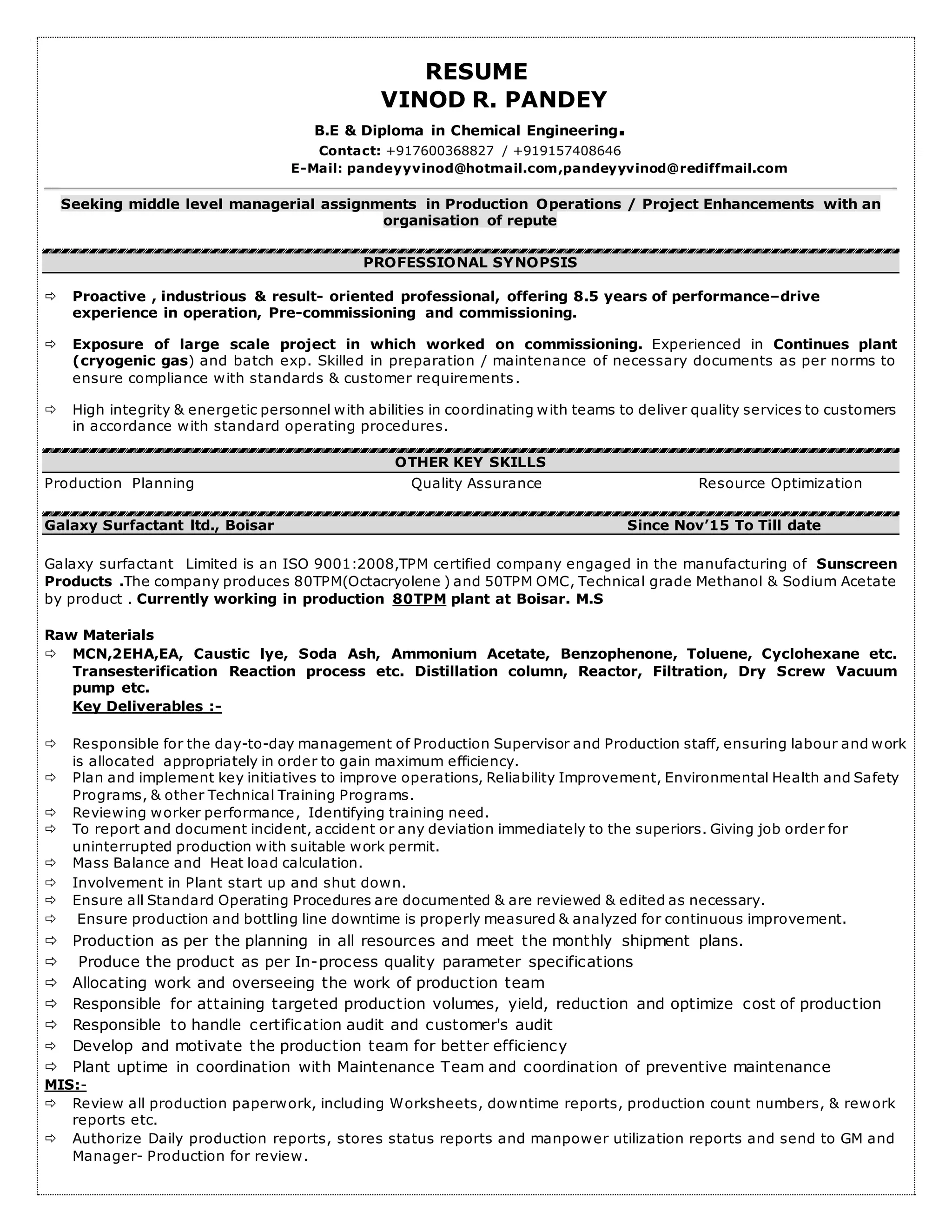

Vinod Pandey is a chemical engineer with over 8 years of experience in production operations and project enhancements. He is currently working as a production supervisor at Galaxy Surfactants Ltd. in Boisar, India. Prior to this, he worked as a senior production engineer at Gujarat Fluorochemicals Ltd. in Dahej and has experience in commissioning large chemical plants. He is seeking a middle management role utilizing his skills in production planning, quality assurance, and resource optimization.