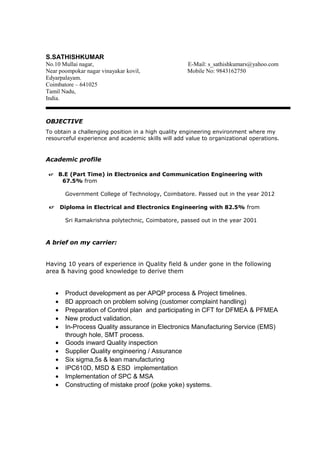

S. Sathishkumar is seeking a challenging position in engineering where he can apply his 10 years of experience in quality control and assurance. He has a diploma in electrical engineering and a bachelor's degree in electronics and communication engineering. His experience includes product development, problem solving, quality inspection, and implementation of quality systems at various electronics and manufacturing companies in Coimbatore, India. He is proficient in quality tools including APQP, FMEA, SPC, auditing, and lean manufacturing techniques.