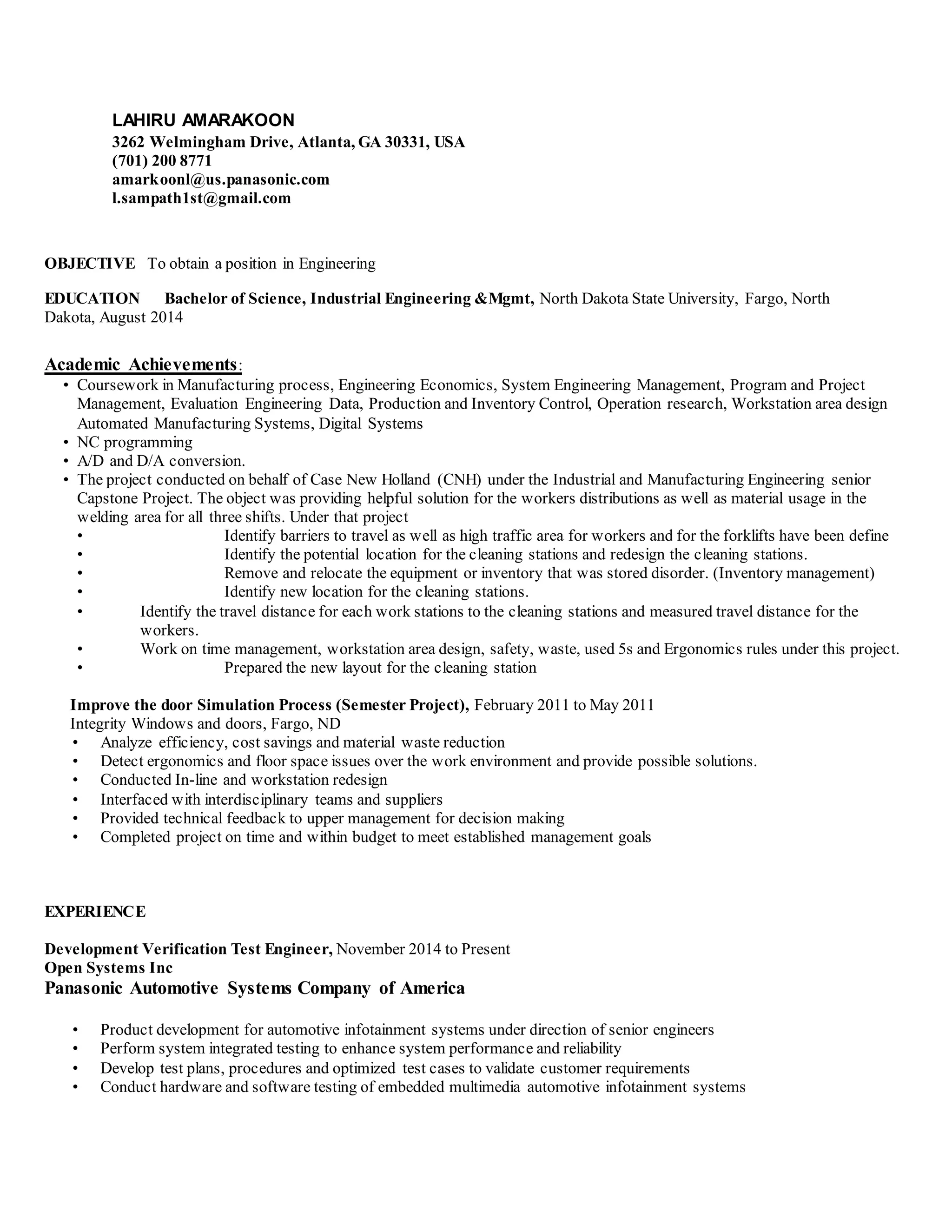

Lahiru Amarakoon is seeking an engineering position and has a Bachelor's degree in Industrial Engineering from North Dakota State University. He has experience as a Development Verification Test Engineer for Panasonic Automotive Systems, where he performed testing of automotive infotainment systems to validate customer requirements and enhance system performance. Previously he conducted a senior capstone project for CNH that redesigned a welding area layout to improve worker and material flow.