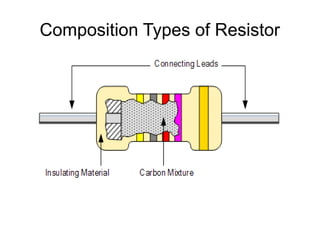

Resistors are passive electrical components that reduce current and voltage. They come in different compositions for various applications. Carbon composition resistors are the most common and economical, but have low precision. Film resistors can be very precise, down to 1% tolerance, through laser trimming of metal films deposited on ceramic. Wirewound resistors can handle high power through a coiled wire element and ceramic former. Different resistor types are suited to applications based on their characteristics like tolerance, frequency response, power rating, temperature coefficient and reliability.