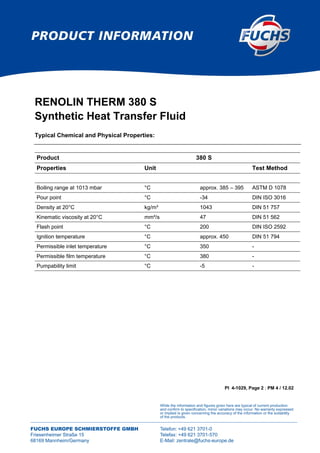

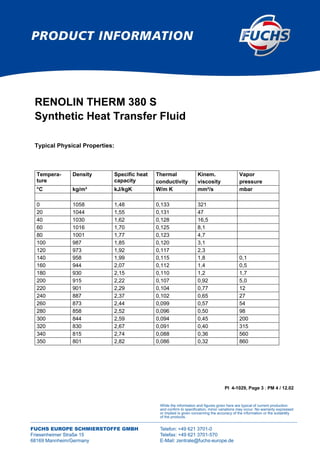

RENOLIN THERM 380 S is a synthetic heat transfer fluid based on isomeric dibenzyl toluenes for use in closed heat transfer systems with forced circulation. It can be used over its entire working range without pressure overlap from 250 to 340°C, with an upper inlet temperature limit of 350°C and a maximum film temperature of 380°C. RENOLIN THERM 380 S has excellent thermal stability, is extremely low-coking, and has a wide service temperature range, low residue formation, good heat transfer properties, protects against corrosion, and has a long service life.