The document discusses various applications for screening buckets, including:

1) Topsoil preparation by screening out stones and debris to produce clean, high-quality topsoil.

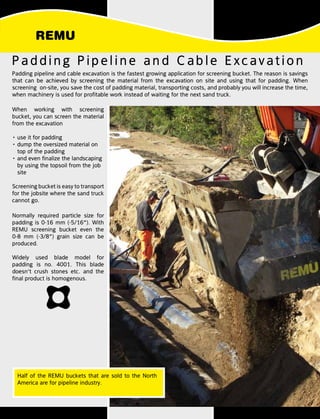

2) Padding pipeline and cable excavations by screening material on-site for padding, saving on transport and material costs.

3) Composting by grinding and screening raw materials and mature compost to produce a homogenous final product.

4) Industrial applications like grinding and classifying chemicals or fertilizers.

5) Screening peat moss to remove stones and debris.

6) Recycling applications like separating materials for further processing.