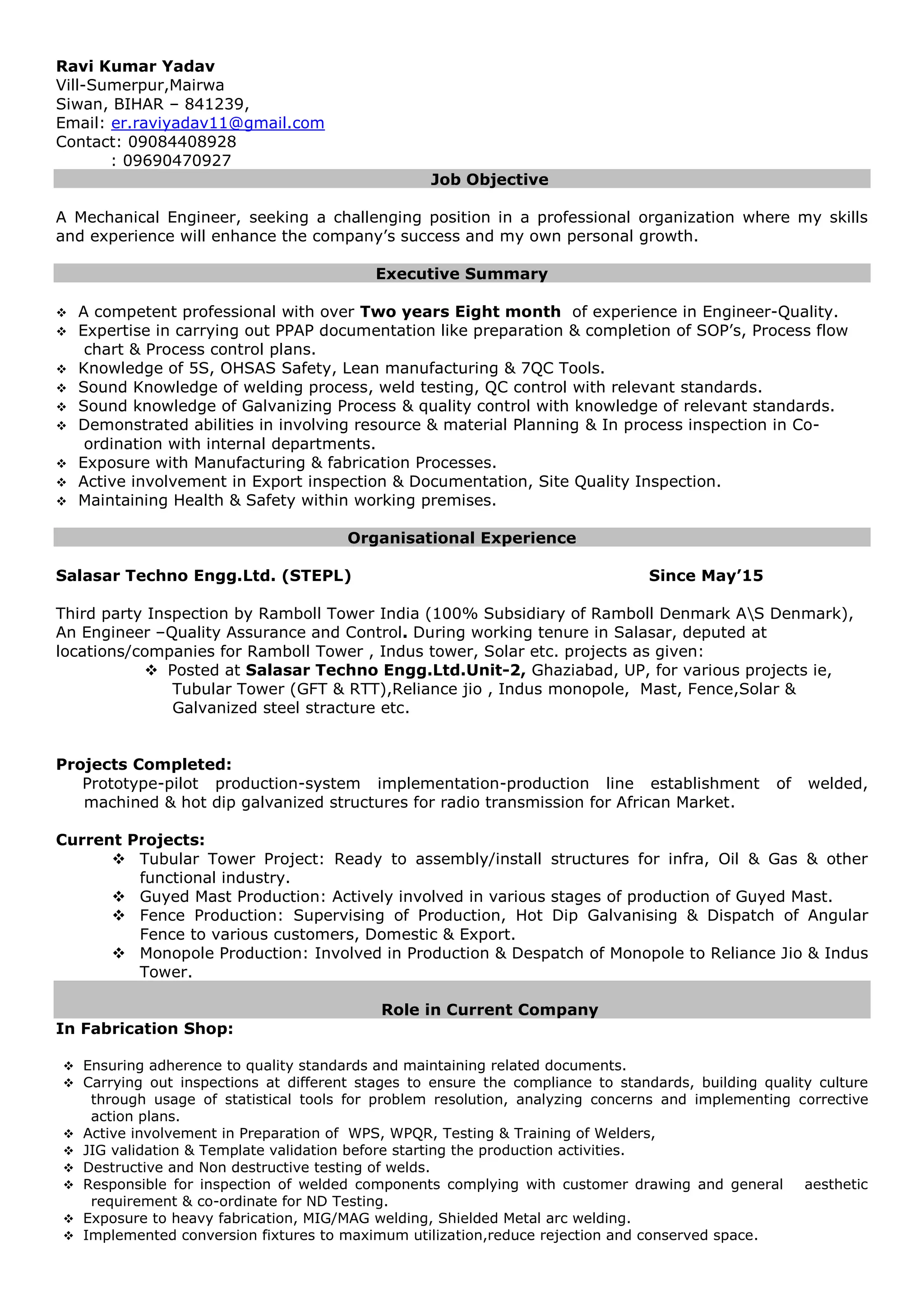

Ravi Kumar Yadav is a mechanical engineer with over two years of experience in quality assurance and control. He currently works for Salasar Techno Engineering where he ensures quality standards are followed across fabrication, welding, galvanizing, and other production processes. Some of his key responsibilities include preparing quality documentation, conducting inspections, training welders, and implementing improvement initiatives. Previously he worked for Balaji Enterprises conducting inspections and quality checks for mechanical and electrical components.