This document outlines a quality control management procedure with 5 key parts:

1) Quality control policy focusing on customer satisfaction and quality improvement.

2) Objectives and targets around customer satisfaction, continuous quality improvement, and building quality.

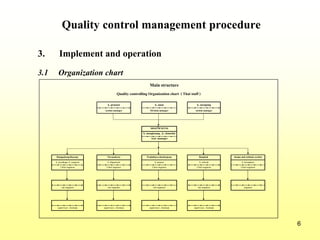

3) Implementation including organization charts, design and procurement responsibilities, and construction process checks.

4) Checking and corrective actions to monitor for issues and make improvements.

5) Management reviews to ensure effective quality control systemwide.