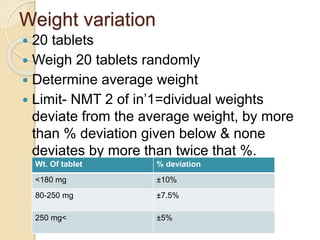

This document discusses quality control tests for tablets, including diffusion, osmosis, hardness, and weight variation. It describes diffusion as the movement of substances from high to low concentration. Osmosis is defined as the movement of solvent molecules through a selectively permeable membrane. Hardness tests involve measuring the load to crush tablets and factors like compressive force and binders. Weight variation tests weigh 20 tablets to check for deviations from the average weight within specified limits based on tablet weight. Methods and equipment for hardness tests, like Pfizer and Monsento hardness testers, are also outlined.