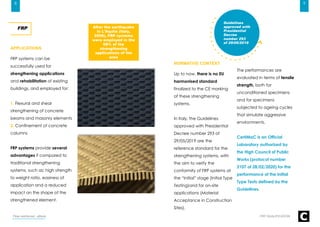

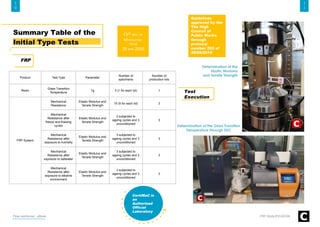

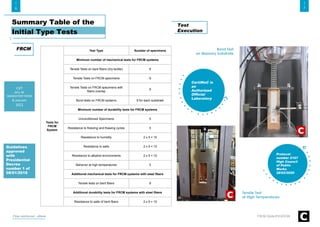

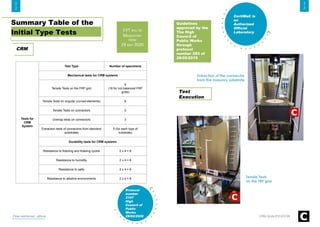

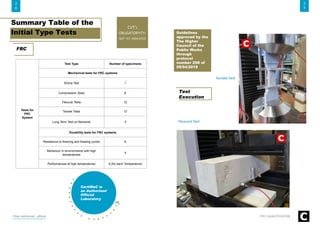

The document outlines the qualifications and guidelines for the use of composite materials in structural applications in Italy, emphasizing the need for a technical assessment certificate (CVT) for these materials not CE marked or lacking European Technical Assessment. It details the mandatory qualifications for four main types of composite materials (FRP, FRCM, CRM, and FRC), which include tests conducted by authorized laboratories like Certimac, to ensure compliance with national standards. The document also highlights the advantages of these composite materials in construction, such as improved strength, reduced weight, and compatibility with existing structures.

![QUALIFICATION

OF COMPOSITE

MATERIALS FOR

STRUCTURAL USE

Guidelines of the Italian High Council of Public Works

E-book by CertiMaC

Authorized official laboratory

for the qualification tests

and the issue of certificates

Protocol No. 2107 - 28/02/2020

E-book|QualificationOfCompositeMaterialsForStructuralUse

[founded and participated by]](https://image.slidesharecdn.com/qualificationofcompositematerialsforstructuralusecertimac-200901102713/85/Qualification-of-composite-materials-for-structural-use_CertiMaC-1-320.jpg)