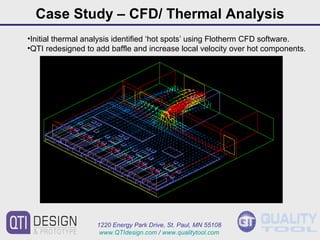

Quality Tool provides mechanical and industrial design services as well as contract manufacturing of metal products. They have two facilities in South Dakota and Minnesota. They specialize in sheet metal enclosures, chassis design, mechanism design, plastic design, electro-mechanical design, bus bar design, and design for manufacturability. Quality Tool works with companies as a design partner from concept through production. They also provide quick-turn prototyping and production verification. Several case studies are presented showing Quality Tool's work on projects such as an electronic enclosure, DFM analysis, CFD/thermal analysis, rivets, latches and levers, an electro-mechanical design, and a coordinate measuring machine.