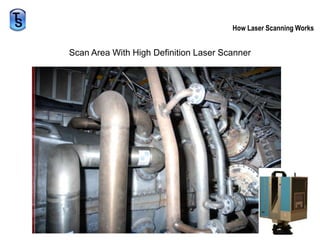

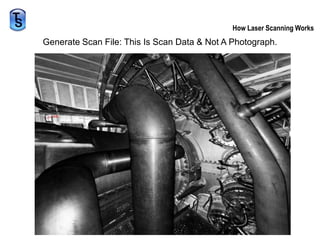

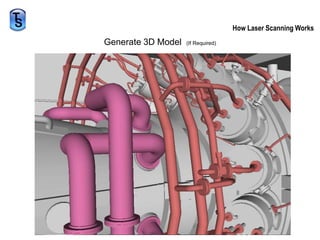

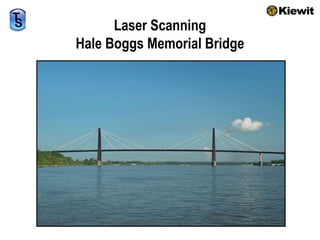

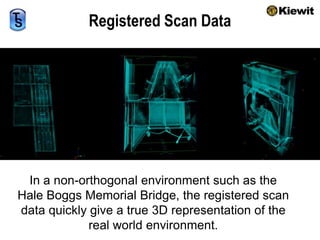

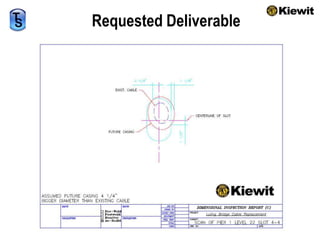

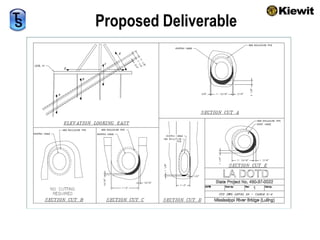

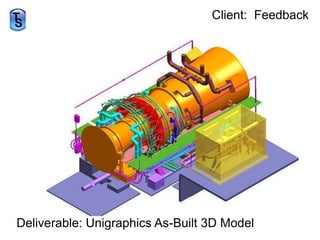

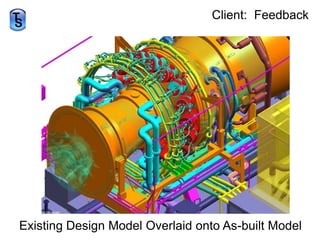

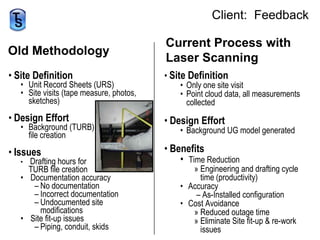

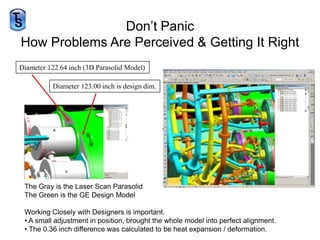

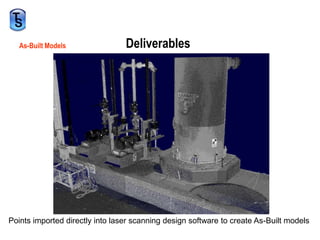

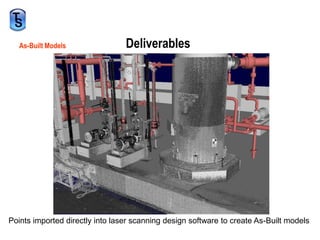

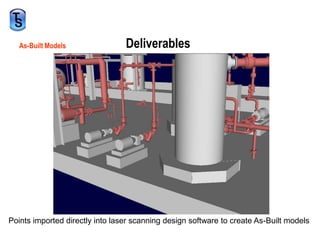

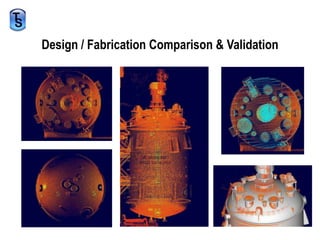

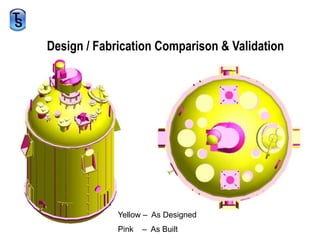

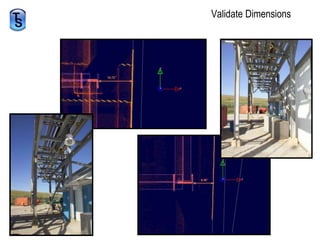

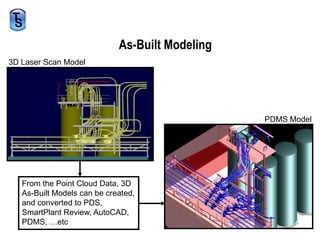

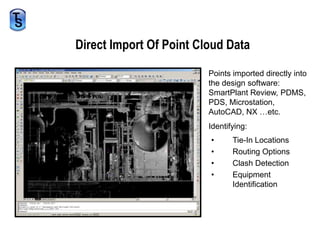

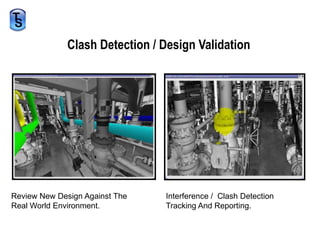

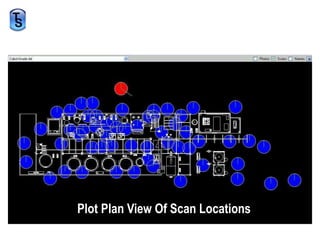

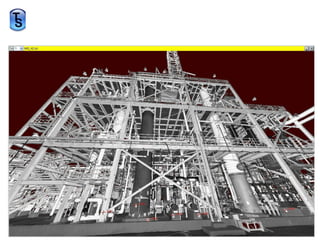

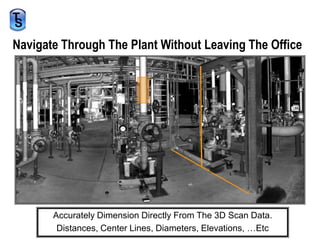

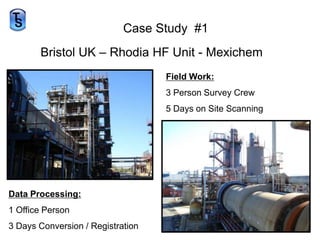

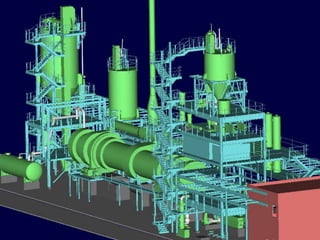

Simon Atkinson has over 15 years of experience providing laser scanning services for as-built modeling. His company, High Definition Digital Survey, uses laser scanning to quickly and safely capture detailed 3D point cloud data on site. This data is then processed and converted into accurate 3D as-built models and other deliverables for engineering design and validation. Laser scanning provides benefits like reduced time and costs, increased safety, and better documentation compared to traditional measurement techniques.