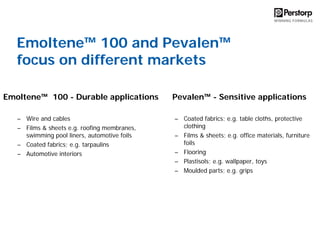

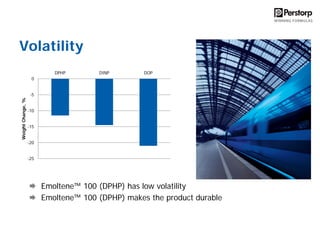

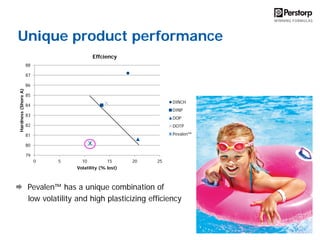

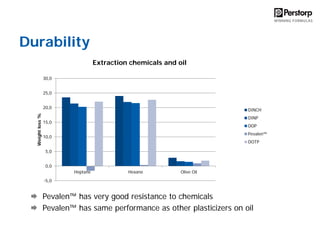

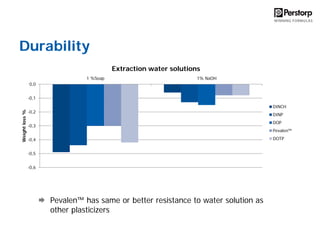

Perstorp, a leading specialty chemicals company, has invested in sustainable plasticizers for the PVC industry, particularly emoltenetm 100 and pevalentm, to enhance product performance and durability. With a focus on European markets, these products are designed for various applications, offering low volatility, high compatibility, and resistance to outdoor conditions. This investment aims to meet rising customer demand and provide innovative, environmentally-friendly solutions in plastic manufacturing.