Embed presentation

Download to read offline

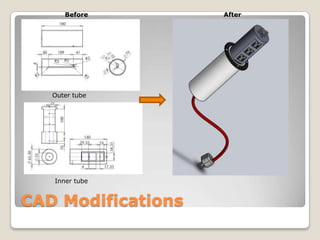

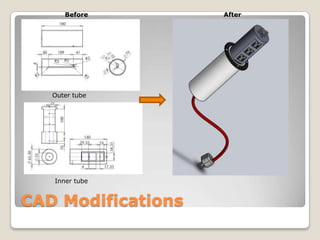

The document summarizes the project first prototype for Group NJT2C. It involved injection molding, joining, and assembling many parts to create the initial model. The manufacturing process included cutting, pushing, joining, and decorating parts. CAD modifications were made to the outer and inner tubes. Problems encountered included parts not fitting due to design limitations and material availability. Solutions involved modifying the CAD and using precise machines for high resolution assembly of smaller parts.