Embed presentation

Download to read offline

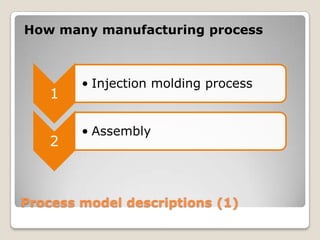

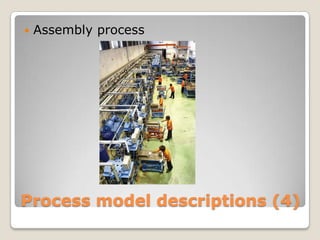

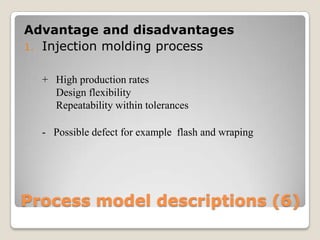

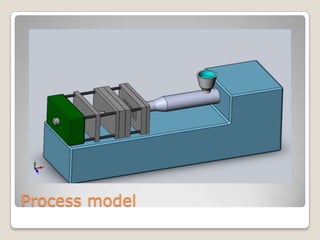

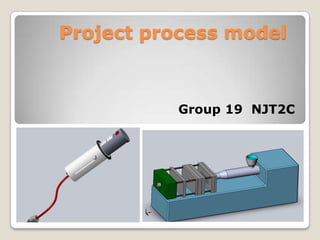

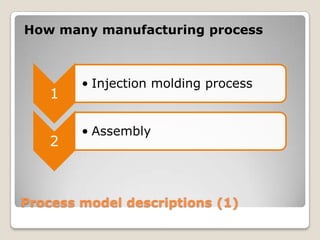

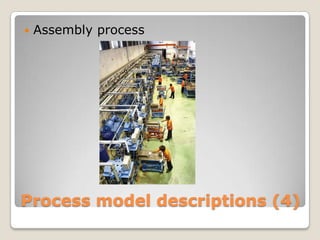

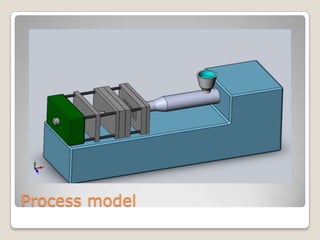

The document describes two manufacturing processes - injection molding and assembly. The injection molding process involves plastic pellets being fed into a hopper, melted, and forced into a mold to form parts, which are then cooled and ejected. The assembly process involves transferring molded parts from the injection molding process using a conveyor belt for further assembly.