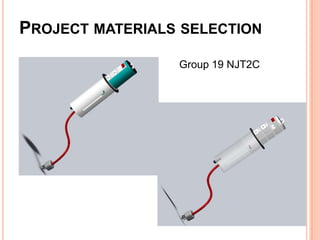

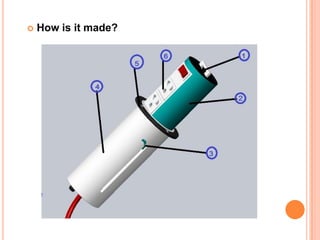

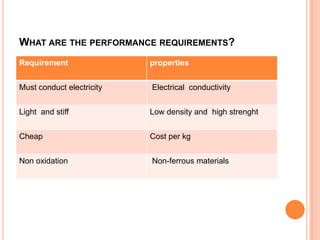

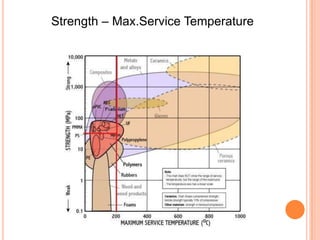

This document discusses the material selection process for a group project to design a universal electrical outlet. It begins by outlining the product requirements, including its intended function of supporting 6 sockets and sliding in/out of a table, costing less than 200 baht, and having a modern appearance. Next, it examines the interacting components and manufacturing process. It then evaluates the performance requirements and suitable materials based on charts of material properties. Several plastic materials are considered based on their mechanical, electrical and thermal properties as well as cost. Finally, the document discusses suitable manufacturing processes and estimates the per-unit manufacturing cost.