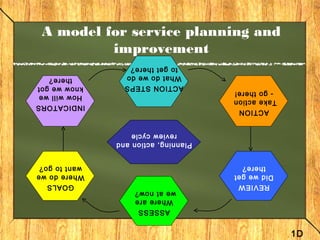

The document discusses strategies for improving productivity. It defines productivity as the ratio of output to input. Productivity can be improved by:

1) Increasing output while keeping input the same.

2) Decreasing input while keeping output the same.

3) Increasing output more than any increase in input.

Some examples provided include shortening production flow paths to increase output without increasing input, using more cost-effective materials to decrease input, and producing new products using existing facilities. Other strategies mentioned are modern manufacturing techniques, waste minimization, training, and supply chain optimization.