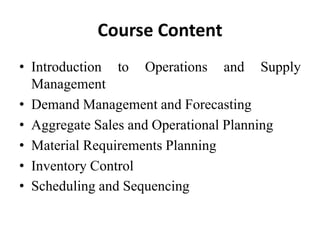

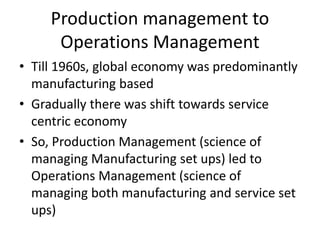

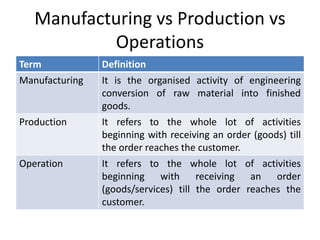

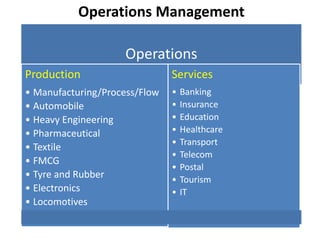

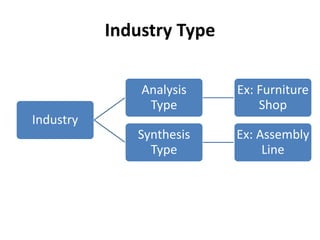

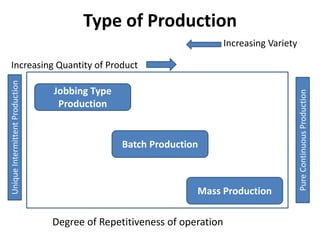

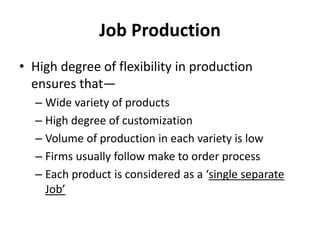

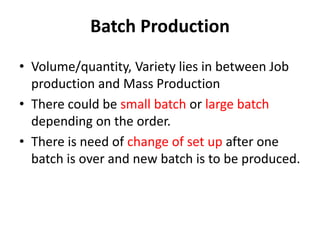

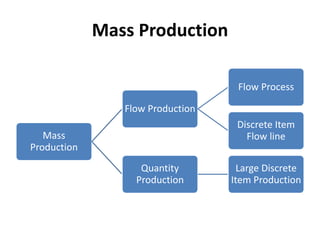

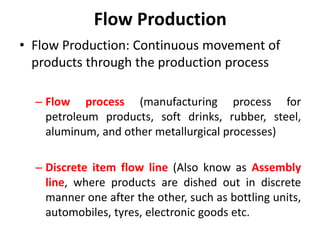

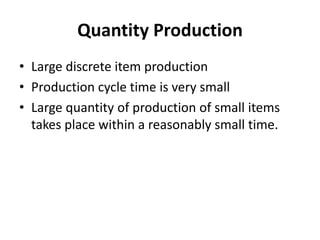

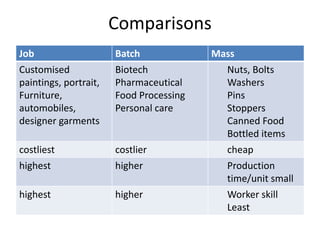

The document outlines the objectives and content of a course on operations management, focusing on production systems, planning, and resource utilization. It distinguishes between manufacturing, production, and operations, and describes various production strategies, including job production, batch production, and mass production. Additionally, it introduces concepts like design to order, make to order, assemble to order, and make to stock, each catering to different customer needs and inventory strategies.