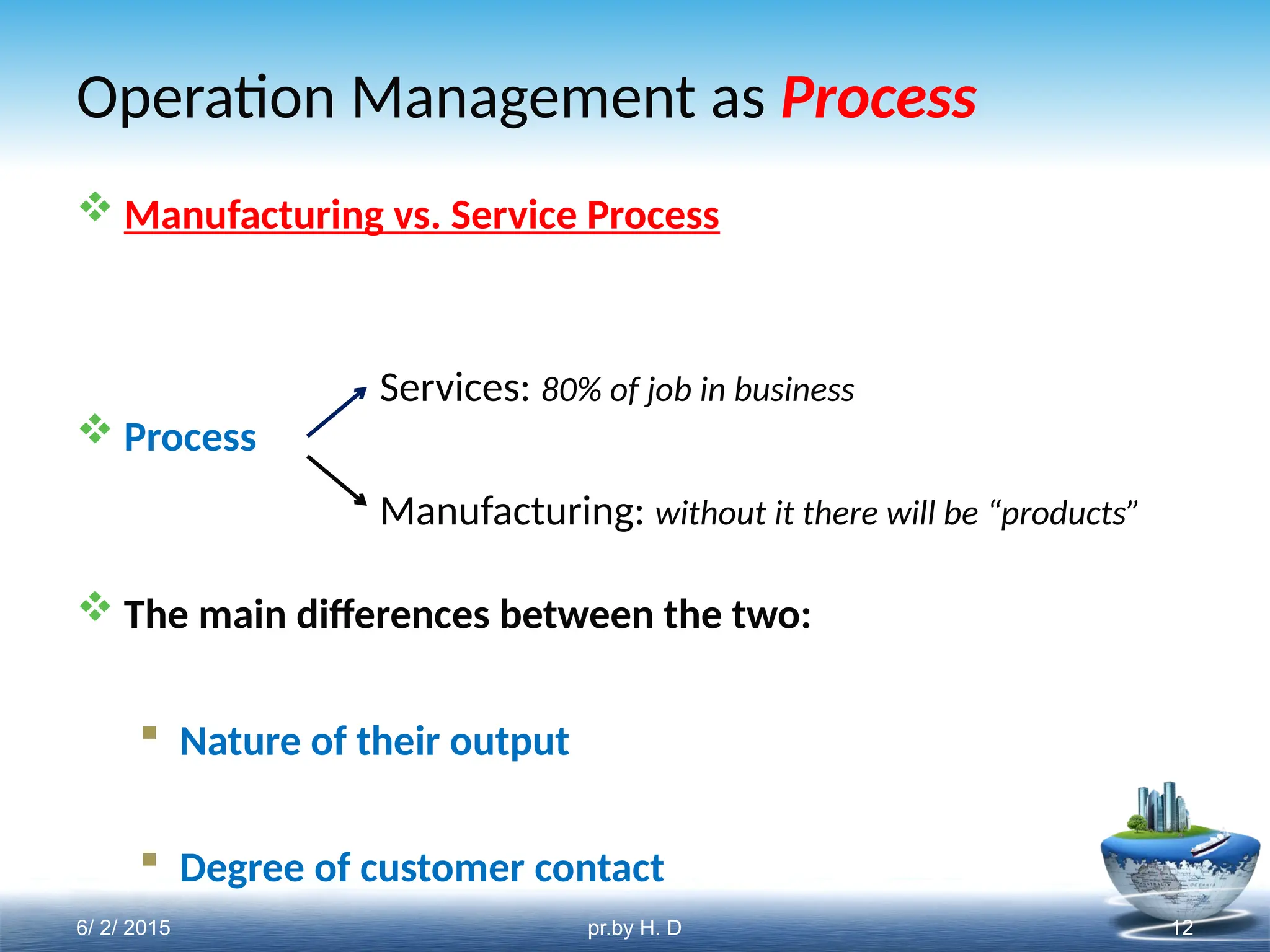

The document outlines the principles of operations management and production systems, highlighting the processes involved in converting inputs into outputs, either goods or services. It differentiates between manufacturing and service operations, emphasizing the importance of understanding customer needs and optimizing production efficiency. Key production types such as job shop, batch, mass, and continuous production are discussed along with their advantages and limitations.