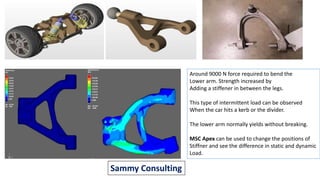

Sammy Consulting leverages Simufact software for simulating various mechanical processes including forming, welding, and 3D printing, achieving satisfactory results in automotive and industrial components. The document outlines various applications of Simufact, such as analyzing stress, temperature, and behavior under loads, along with unconventional forming processes and innovative design concepts. Multiple simulation examples are provided, highlighting the software's accuracy in predicting forces and the potential for product optimization.