1. The document outlines the design process for a portable heating device called a "cuptle" that allows users to heat drinks.

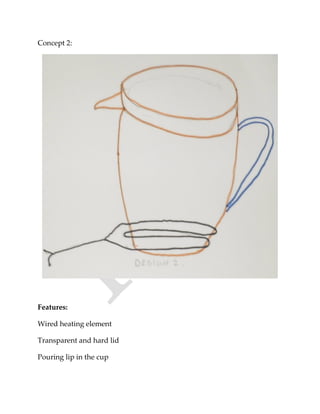

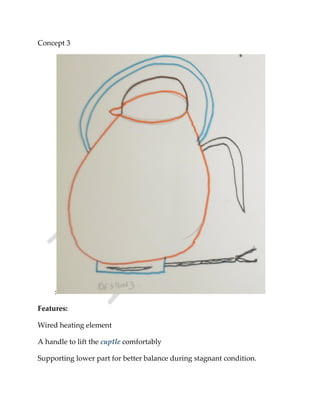

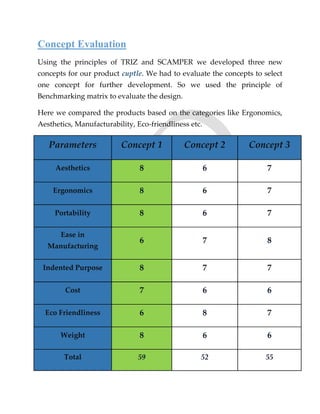

2. Three concepts for the cuptle were developed using tools like mind mapping, SCAMPER, and TRIZ. Concept 1 was selected which featured a segregated heating coil and cup with temperature sensors and timers.

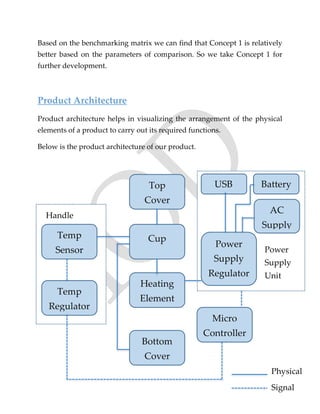

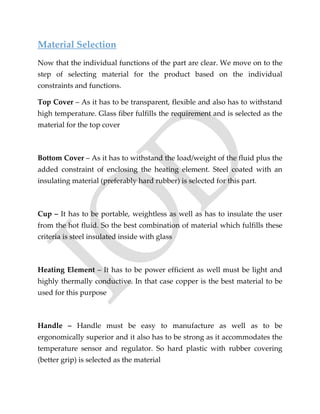

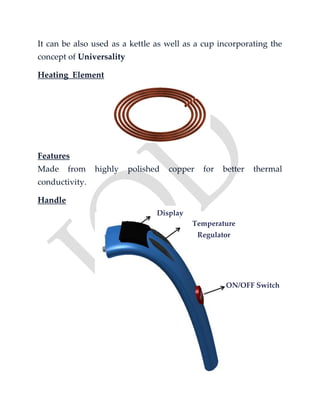

3. The final design of the cuptle has a transparent top cover, strong steel bottom cover enclosing the heating element, and an insulated steel cup that can be used as a kettle or cup. It is powered by batteries or USB and has a temperature display and regulator.