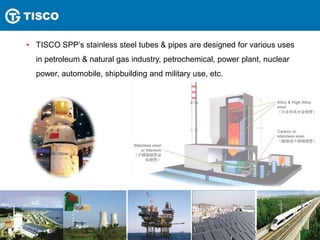

TISCO SPP produces stainless steel tubes and pipes for various industries including petroleum, natural gas, petrochemicals, power plants, automobiles, and ships. The plant has an annual production capacity of 50,000 tons for seamless pipes and 10,000 tons for welded pipes in diameters ranging from 6-762 mm and wall thicknesses from 0.5-40 mm. Products are made from various stainless steel grades including austenitic, martensitic, ferritic, duplex, and nickel alloys. The plant has extensive production facilities including extrusion presses, rolling mills, heat treatment systems, non-destructive testing equipment, and a technology research center to ensure high quality products.

![Inner and outer Seamless

surfaces smooth (Ra 1.0 μm)

304 pitting corrosion

(6%FeCl3+0.05mol/L of

HCl,35℃,24 hour)

15.58

14.65

0 3 6 9 12 15

A厂

太钢

平均腐蚀率g/(m2·h)

TP347H expanding

rate :50%, taper

reaming:60 °

Good cold performanceGood corrosion resistance Excellent surface quality

Small number of inclusions, the

maximum size of less than 10μm[O] Content compared

Physical quality of the main products

Compared products quality with foreign counterparts enterprises, the main quality

characteristics is roughly equal.](https://image.slidesharecdn.com/bb502481-00c2-4045-9bd2-75da73e2d461-160322054158/85/Product-Catalog-27-320.jpg)