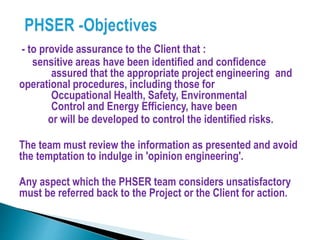

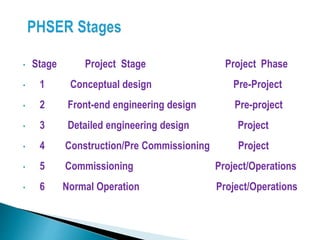

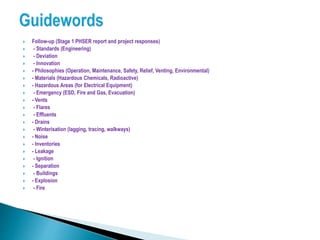

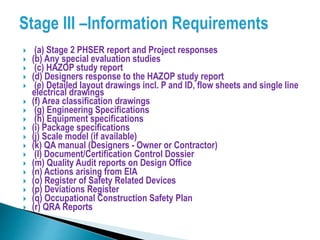

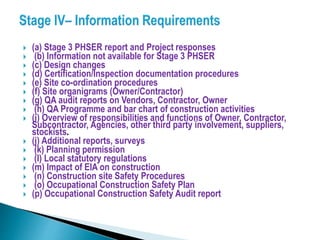

The document outlines a comprehensive approach to risk and safety studies for projects, emphasizing the importance of identifying sensitive areas and implementing appropriate engineering and operational procedures to manage risks. It details various project stages, required documentation, evaluation criteria, and safety measures, particularly concerning hazardous environments such as battery rooms. The focus is on ensuring safety during construction and normal operations while adhering to environmental standards and health regulations.