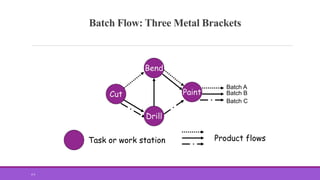

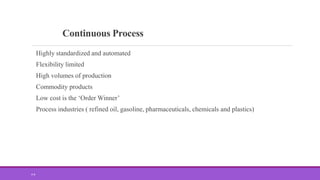

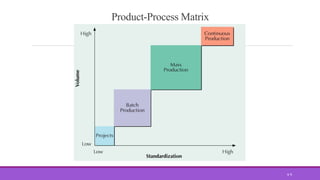

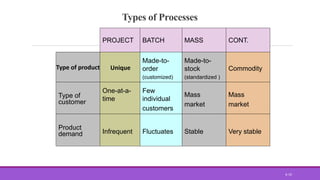

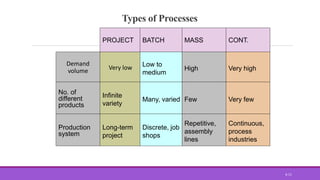

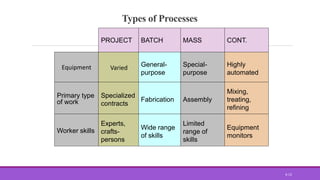

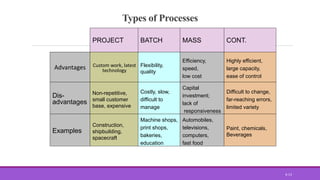

There are four main types of production processes: project, batch, assembly line, and continuous. Project processes involve unique one-of-a-kind products like bridges or aircraft built on-site. Batch processes produce batches of products that flow together through work centers like furniture or dishes. Assembly lines use automation to produce high volumes of standardized discrete products like cars or appliances. Continuous processes are highly automated and standardized to produce high volumes of commodity products like oil, chemicals, or plastics.