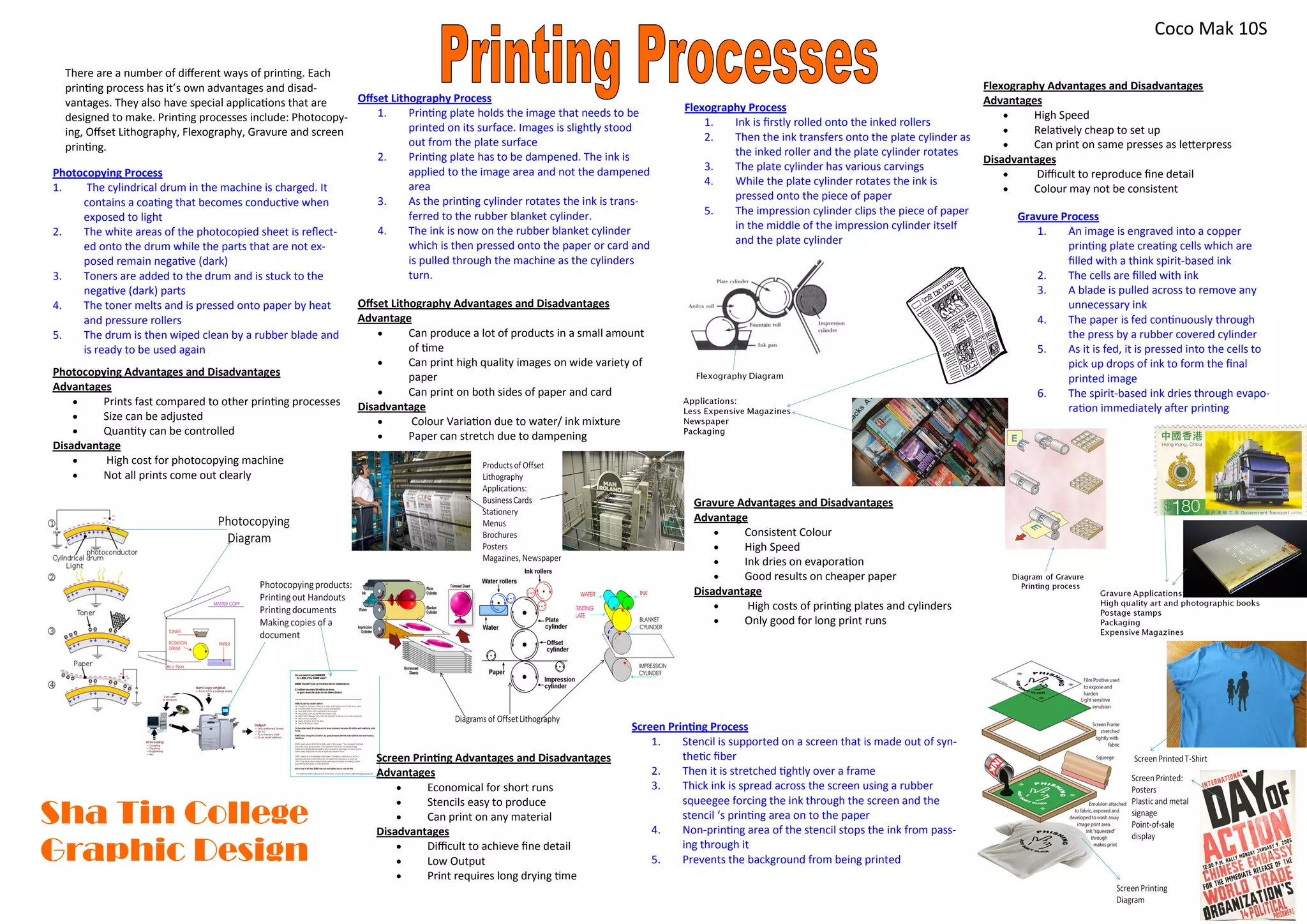

The document discusses several printing processes and their advantages and disadvantages:

1) Offset lithography allows for high quality printing on various papers and can print on both sides. However, it is susceptible to color variation.

2) Flexography is a high speed process but has difficulty reproducing fine detail and consistent color.

3) Gravure provides consistent color and works well on cheaper papers, but the printing plates and cylinders are expensive to produce. It is best for long print runs.

4) Screen printing is economical for short runs and stencils are easy to produce, but it has limited applications.