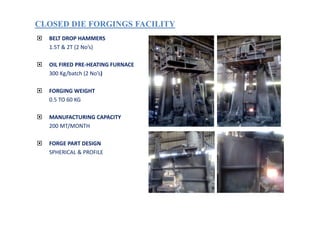

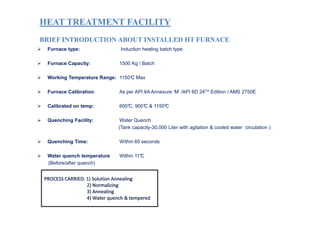

Pressfab Engineering India Pvt. Ltd. is a forging and heat treatment company established in 1995. They operate closed die forging hammers up to 2 tons and can heat treat over 1 metric ton per batch. The company serves domestic and international customers in industries such as oil and gas, valves, automotive, and gears. Their quality management system is certified to ISO 9001:2008 and they specialize in forged, heat treated, and machined components from various alloy grades.