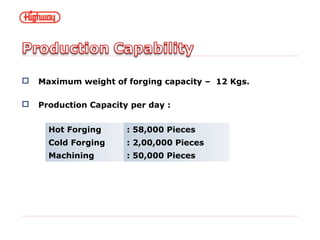

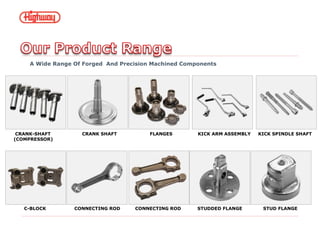

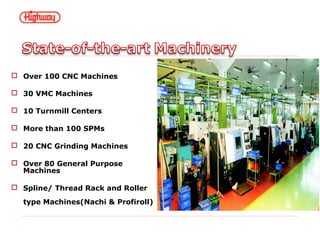

This document summarizes information about a manufacturing company with three production units. The company produces forged and machined components for automotive and engineering industries. Unit I has 9,000 square meters of space and 500 employees working in precision machining and hot/cold forging. Unit II has 5,300 square meters of space and also has 500 employees working in precision machining, hot forging, and SPM manufacturing. Unit III is the largest with 22,000 square meters of space and 1,100 employees working in precision machining and hot/warm forging. The company was incorporated in 1971 and has over 2,200 employees and an annual turnover of $60 million. It supplies components to several major automotive companies.