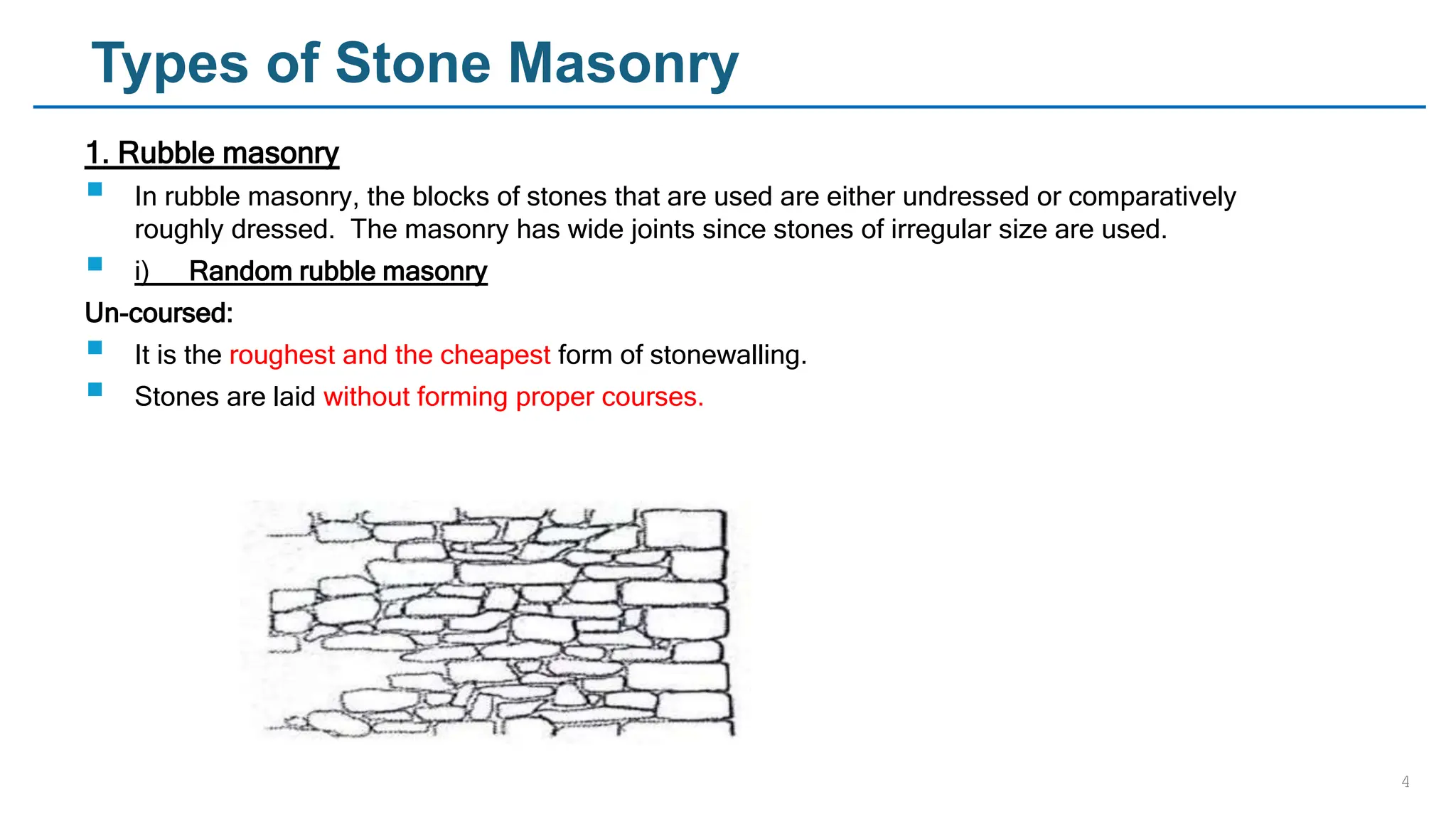

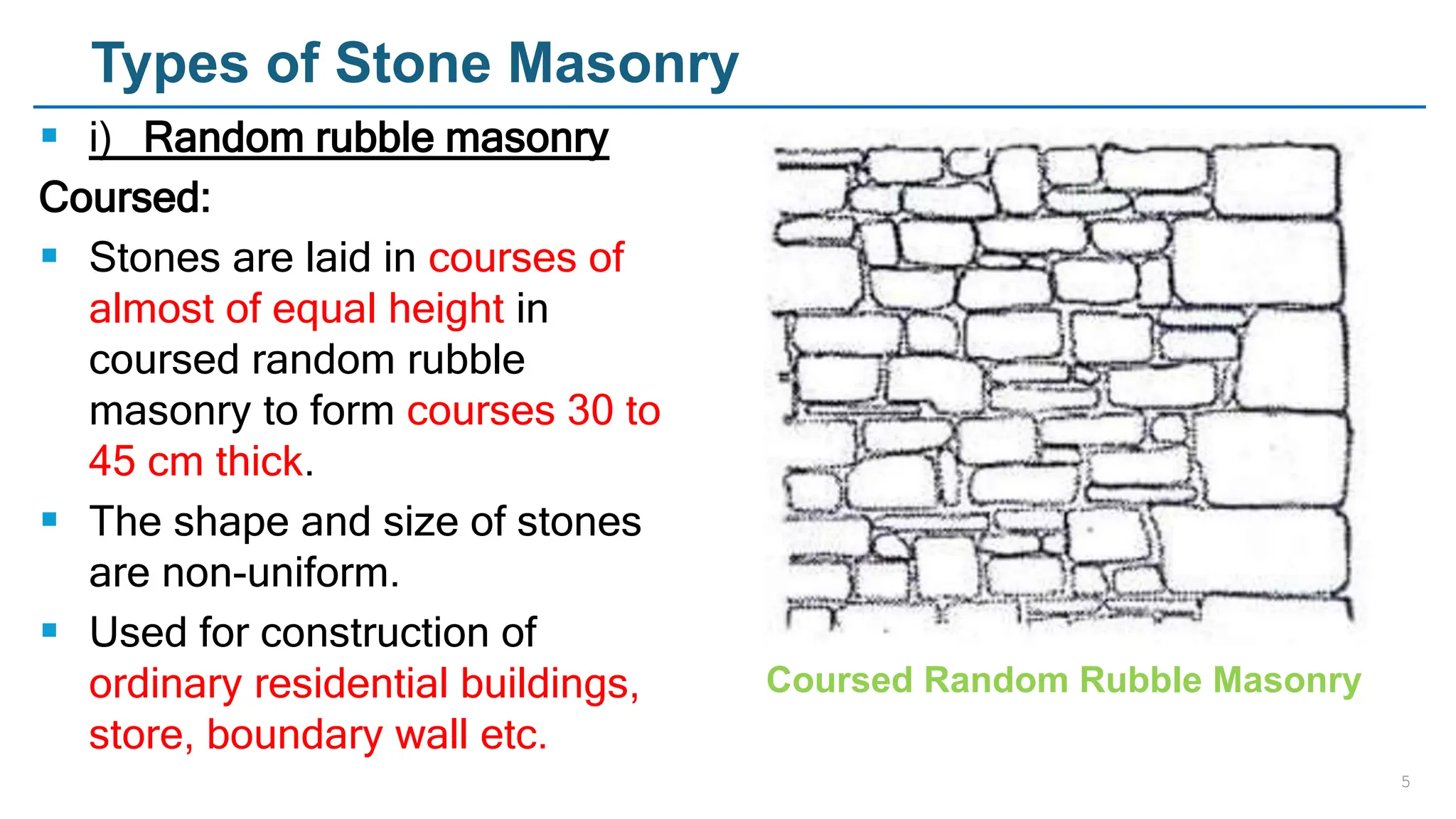

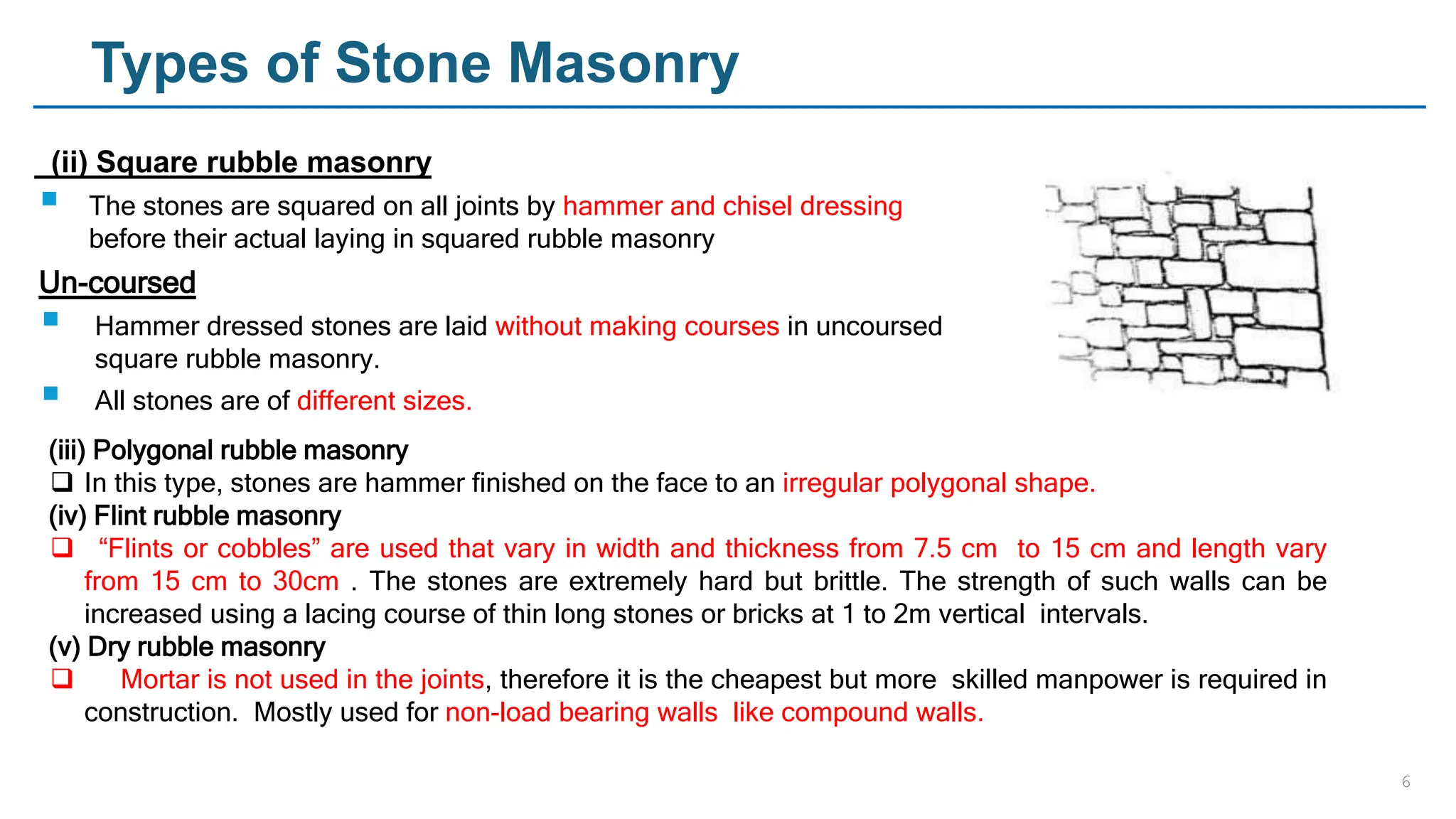

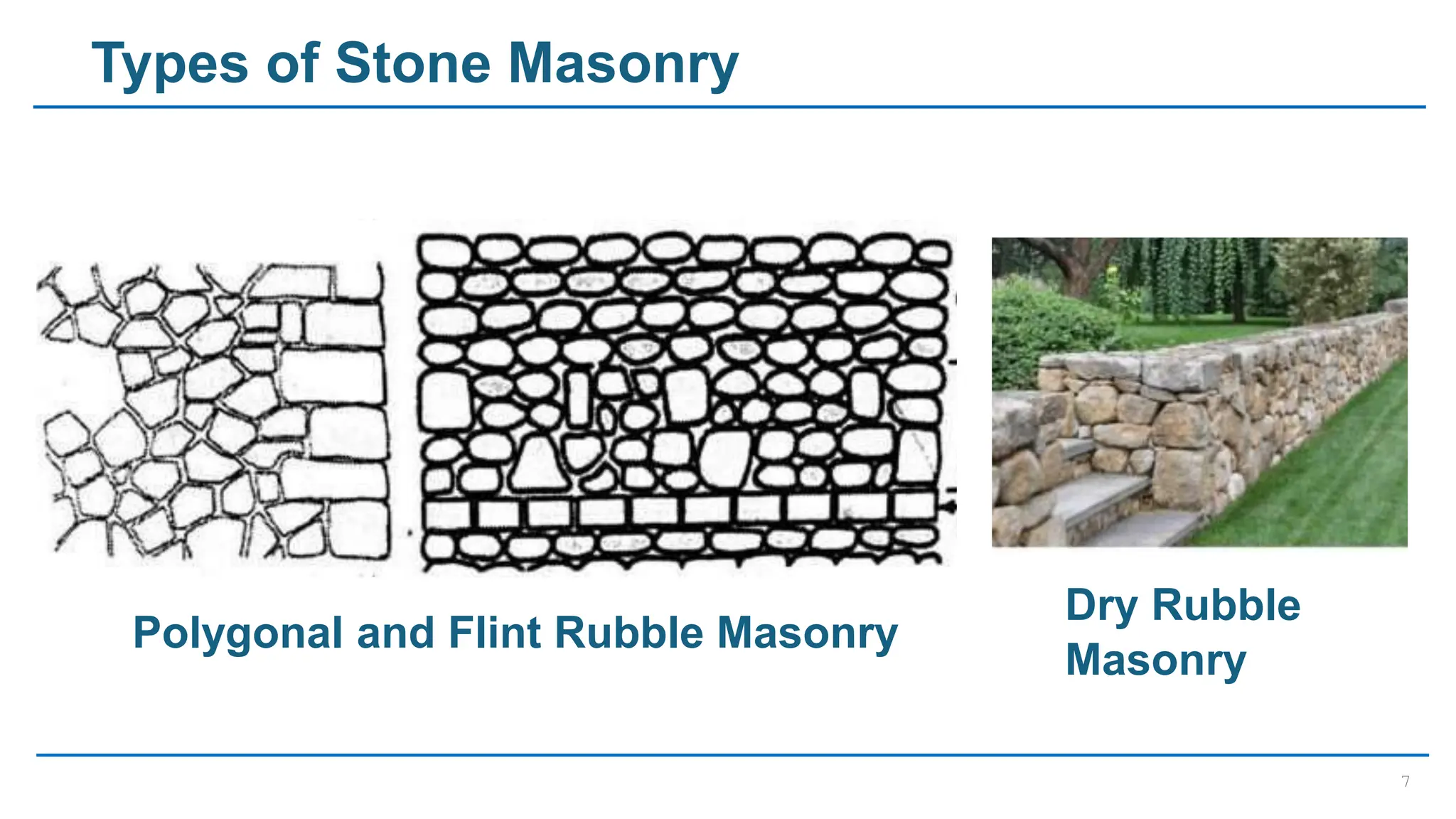

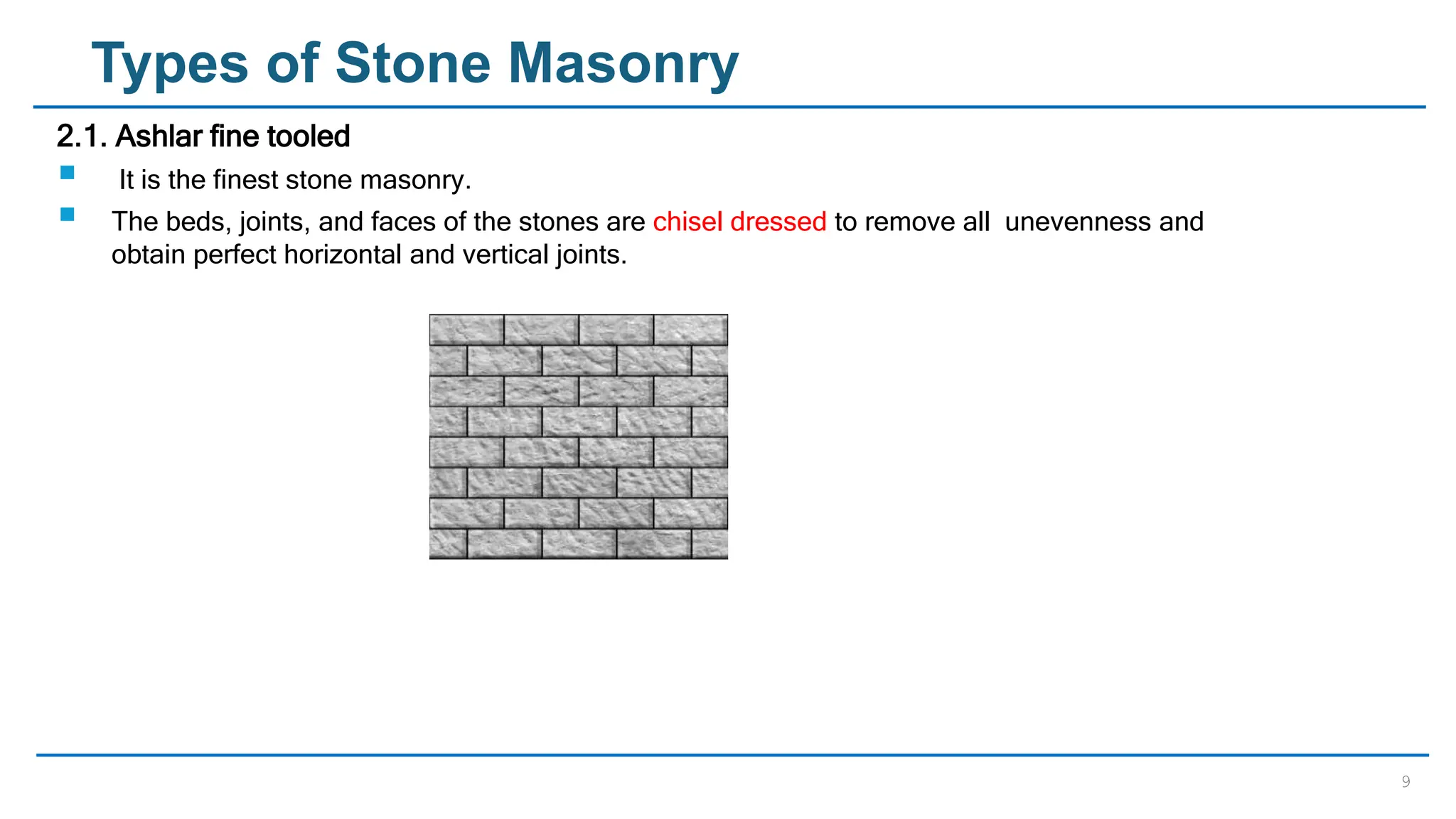

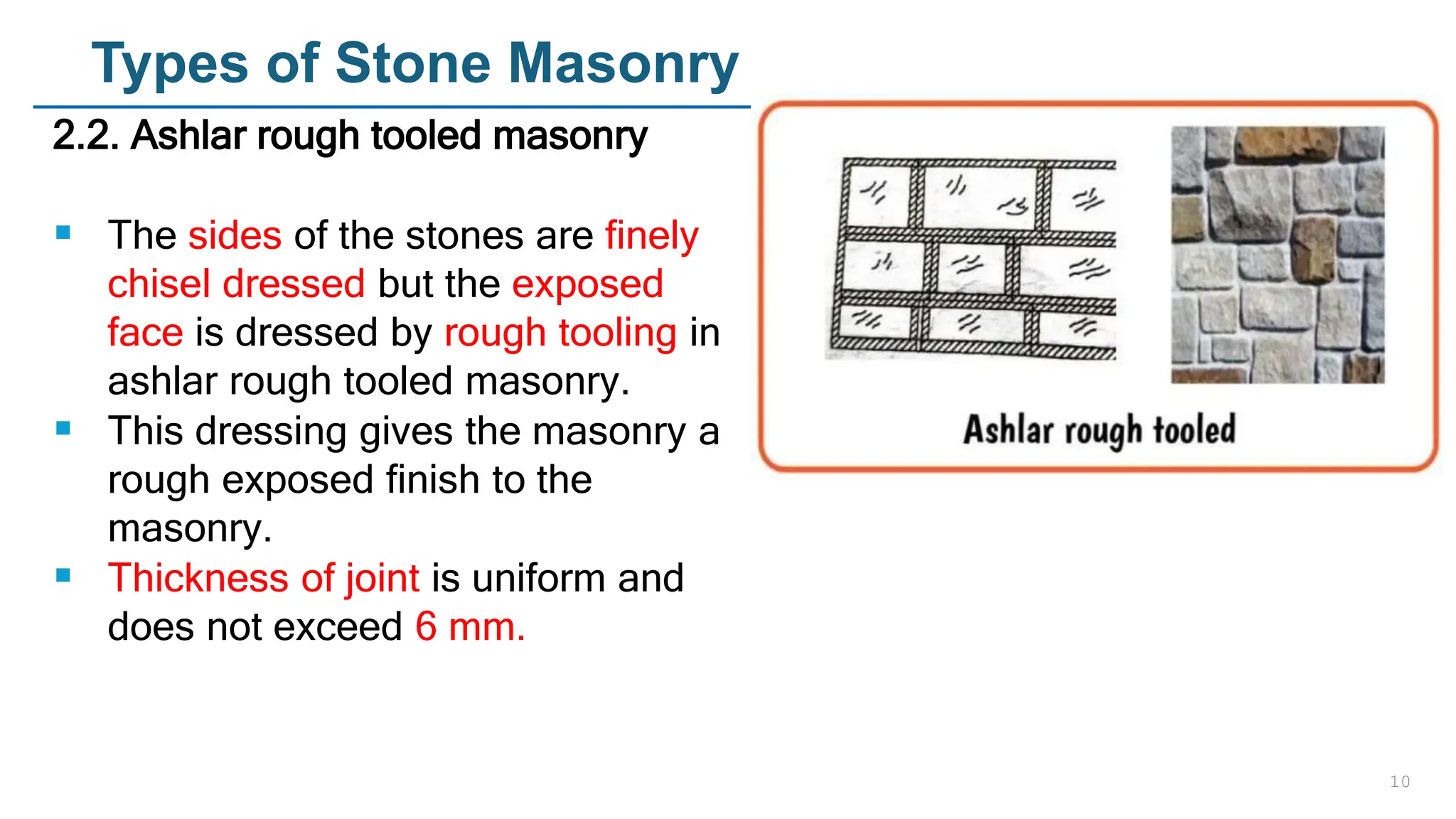

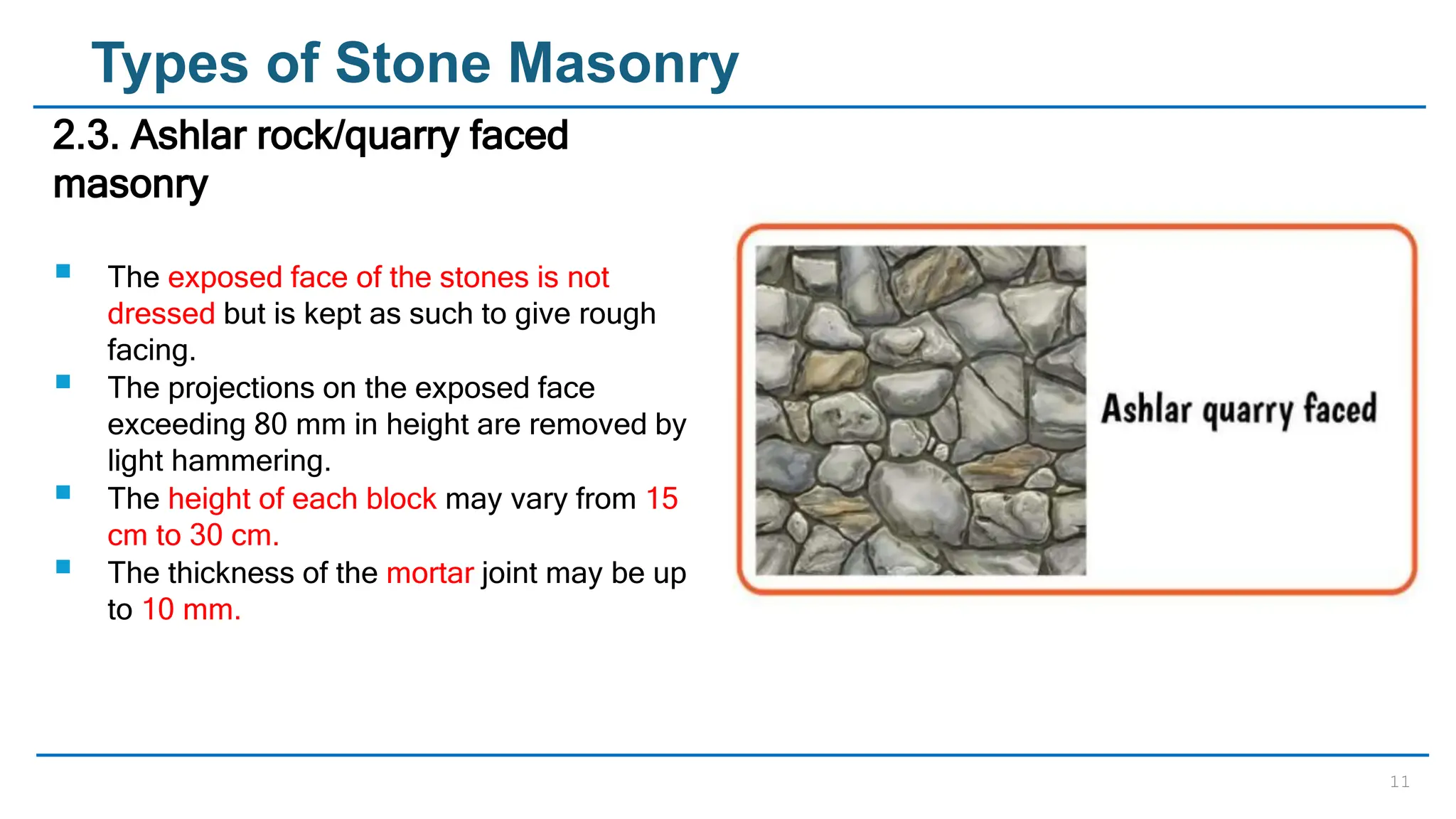

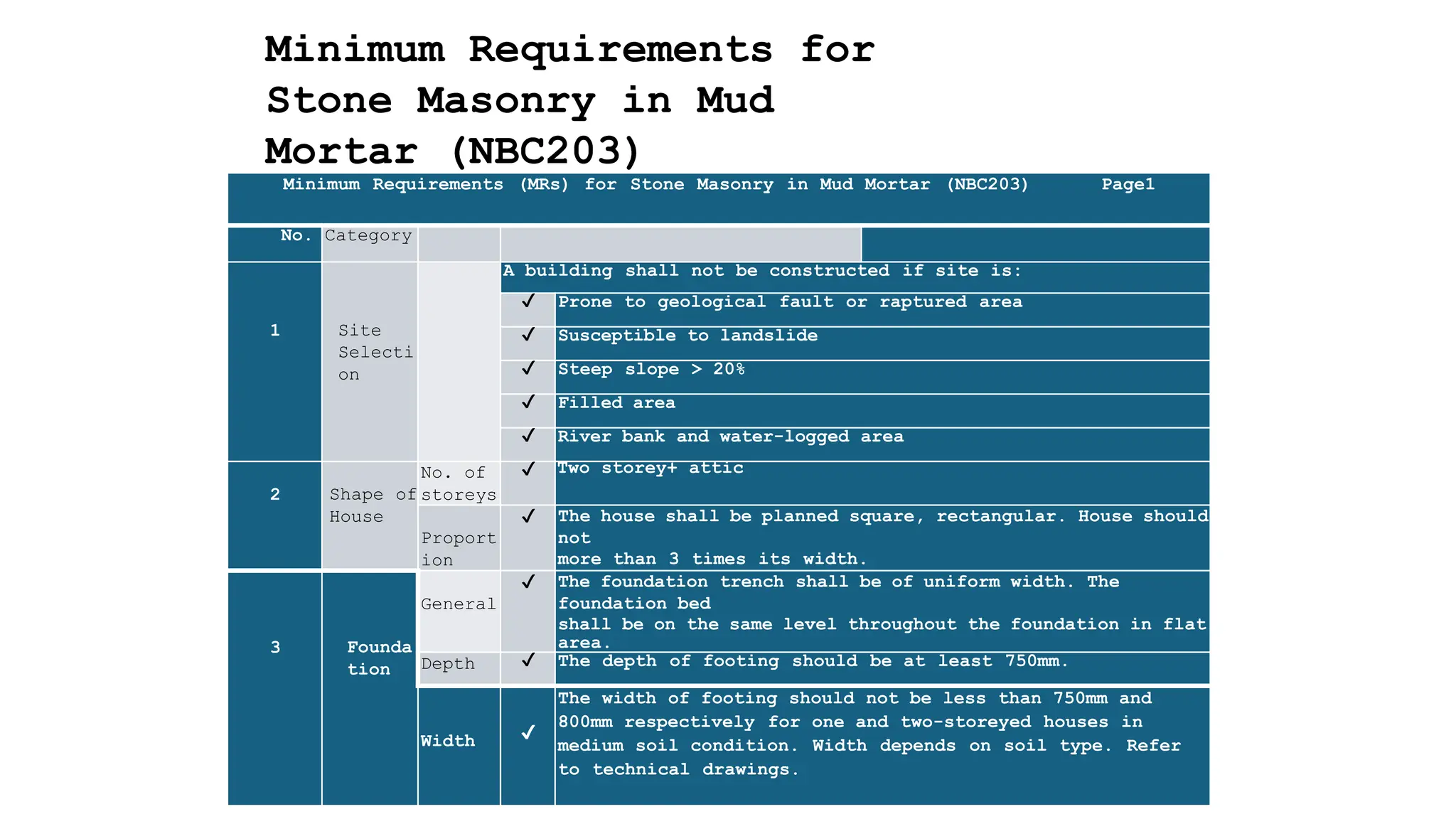

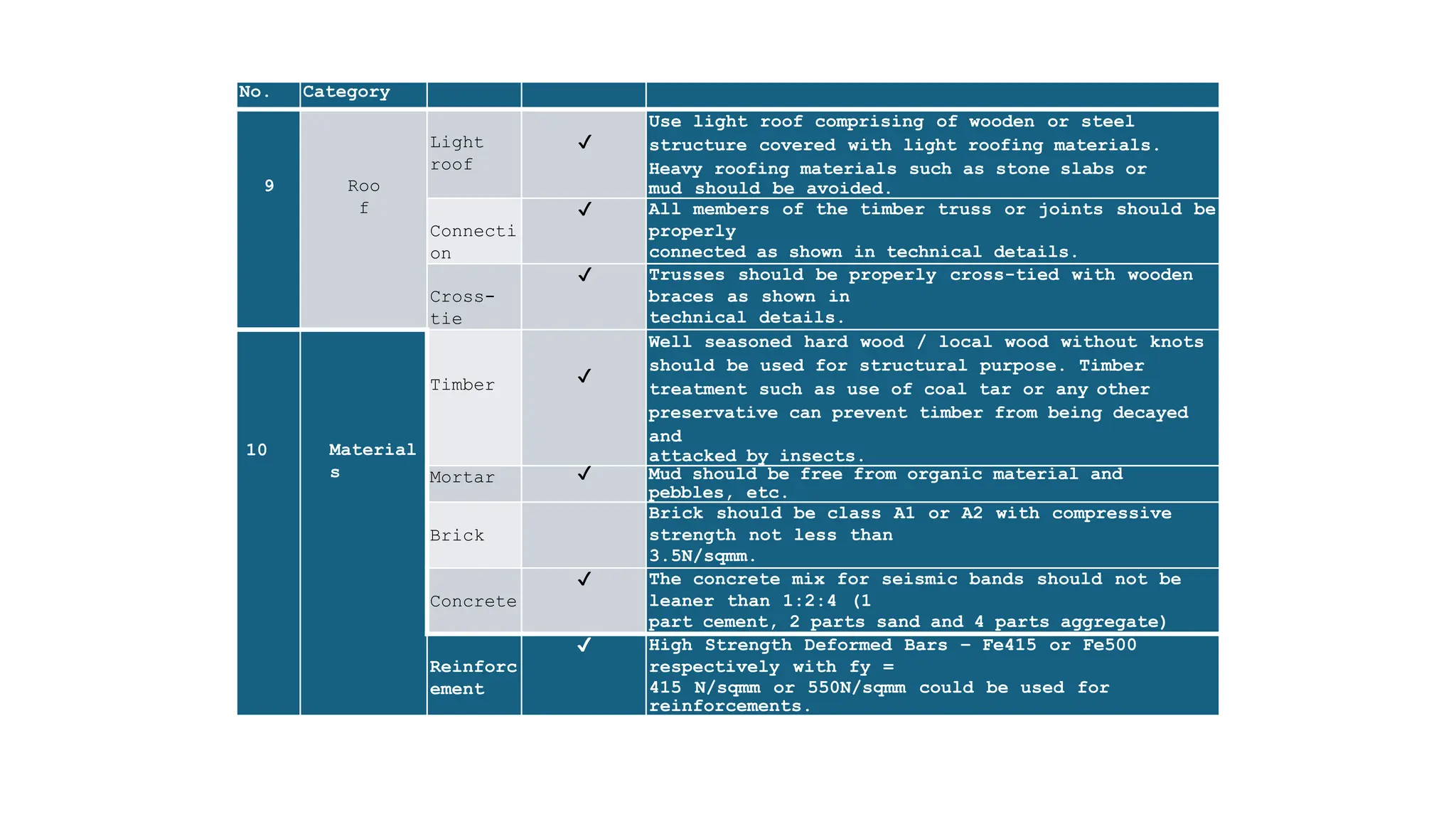

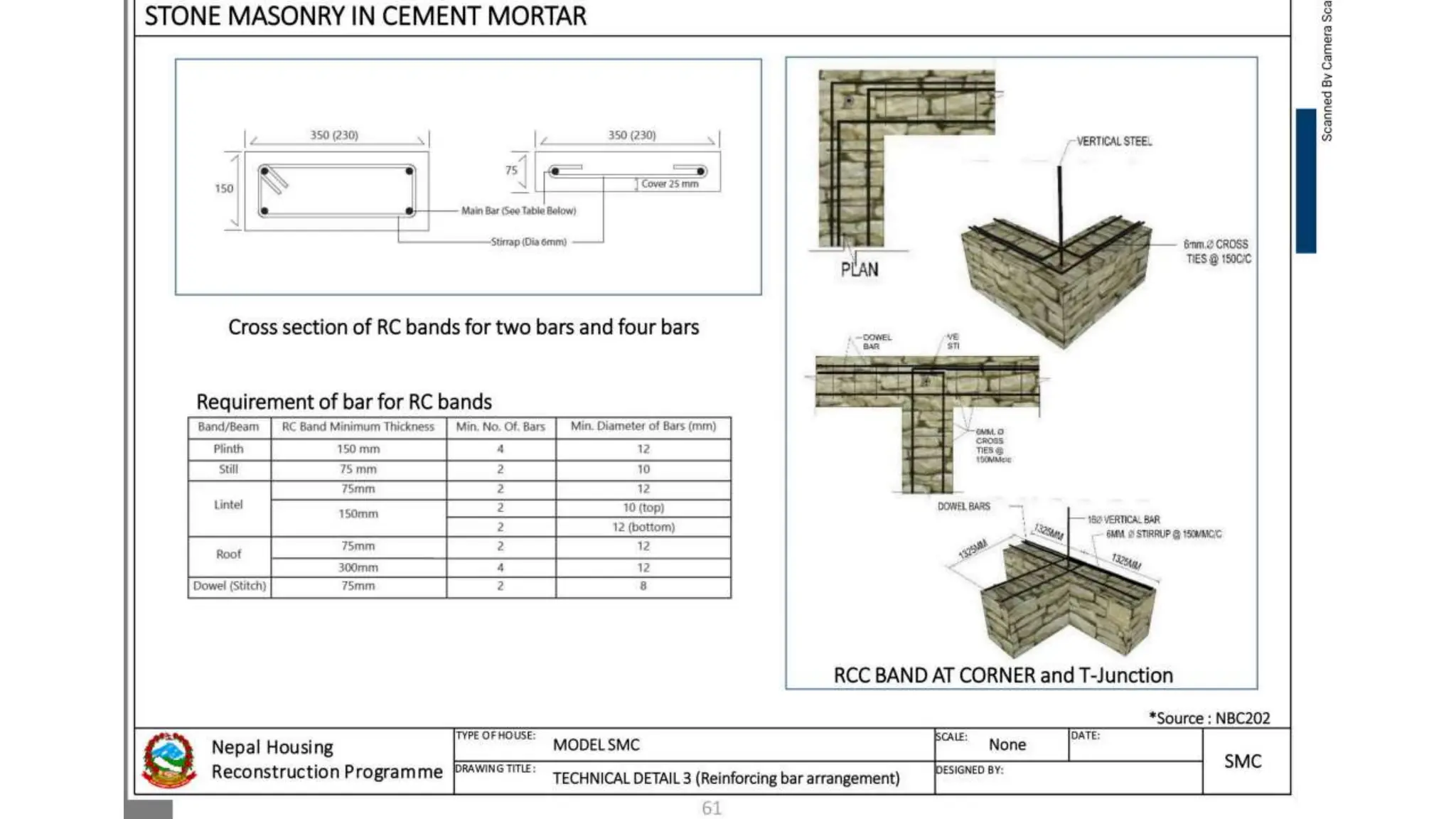

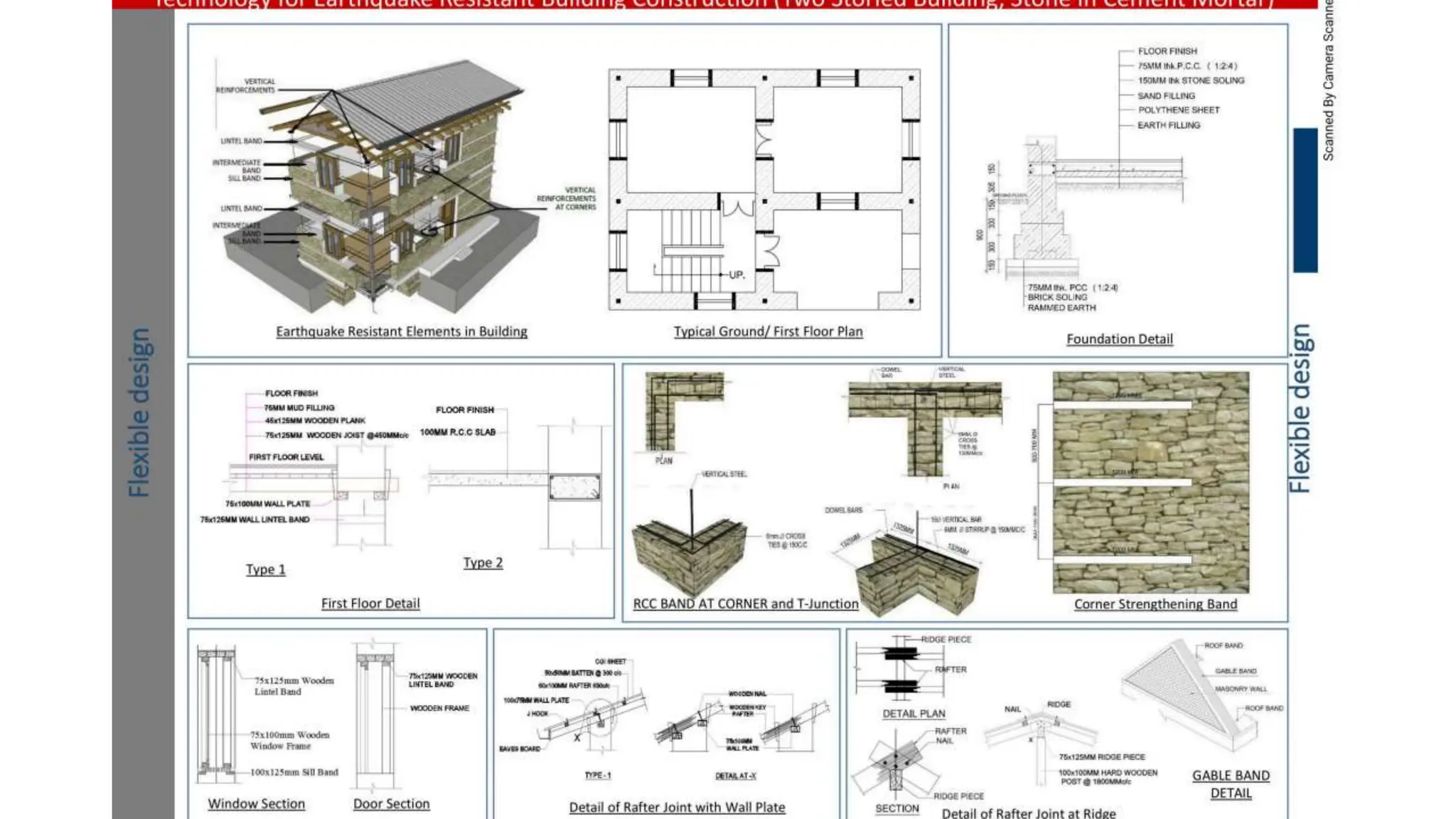

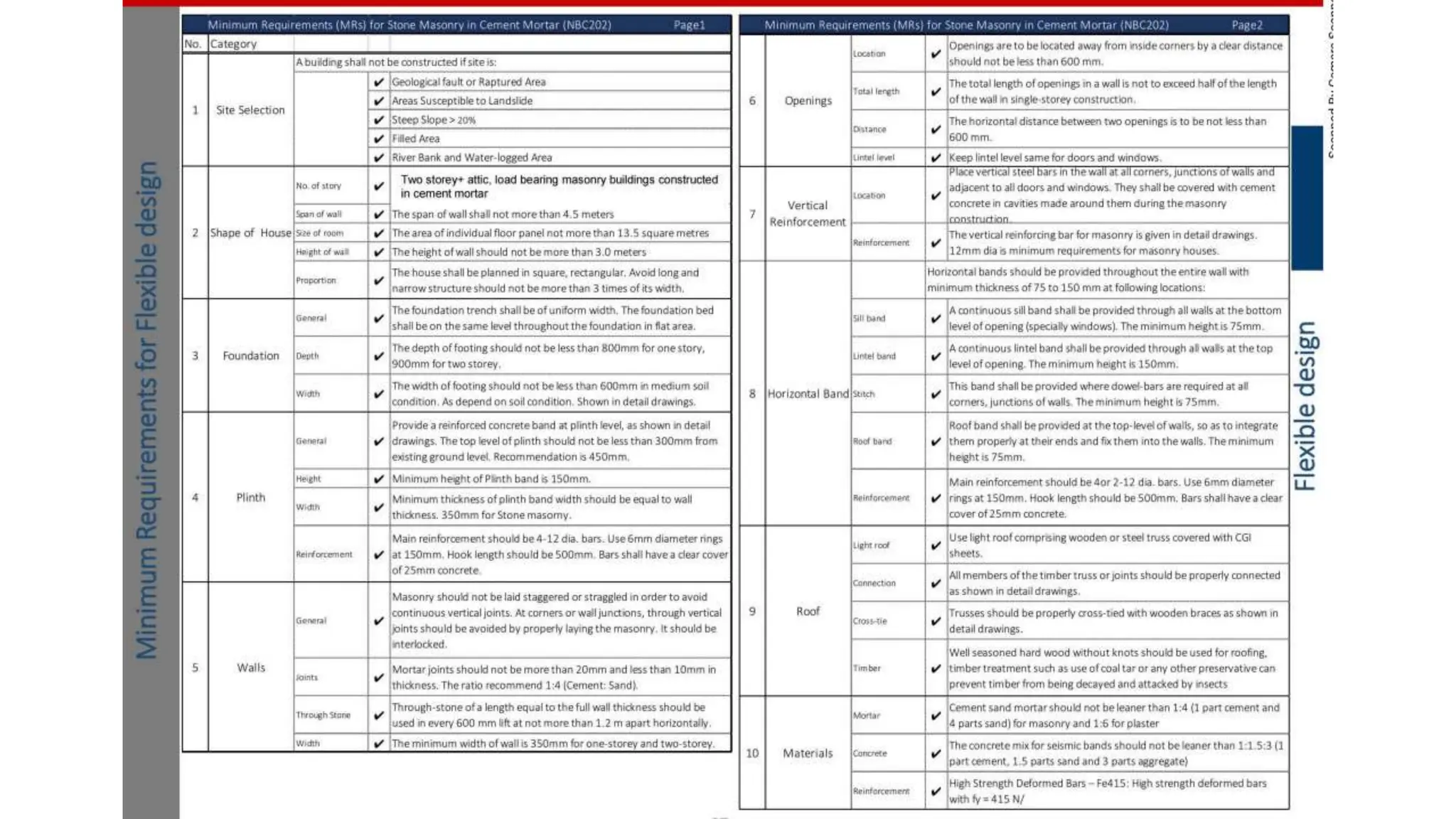

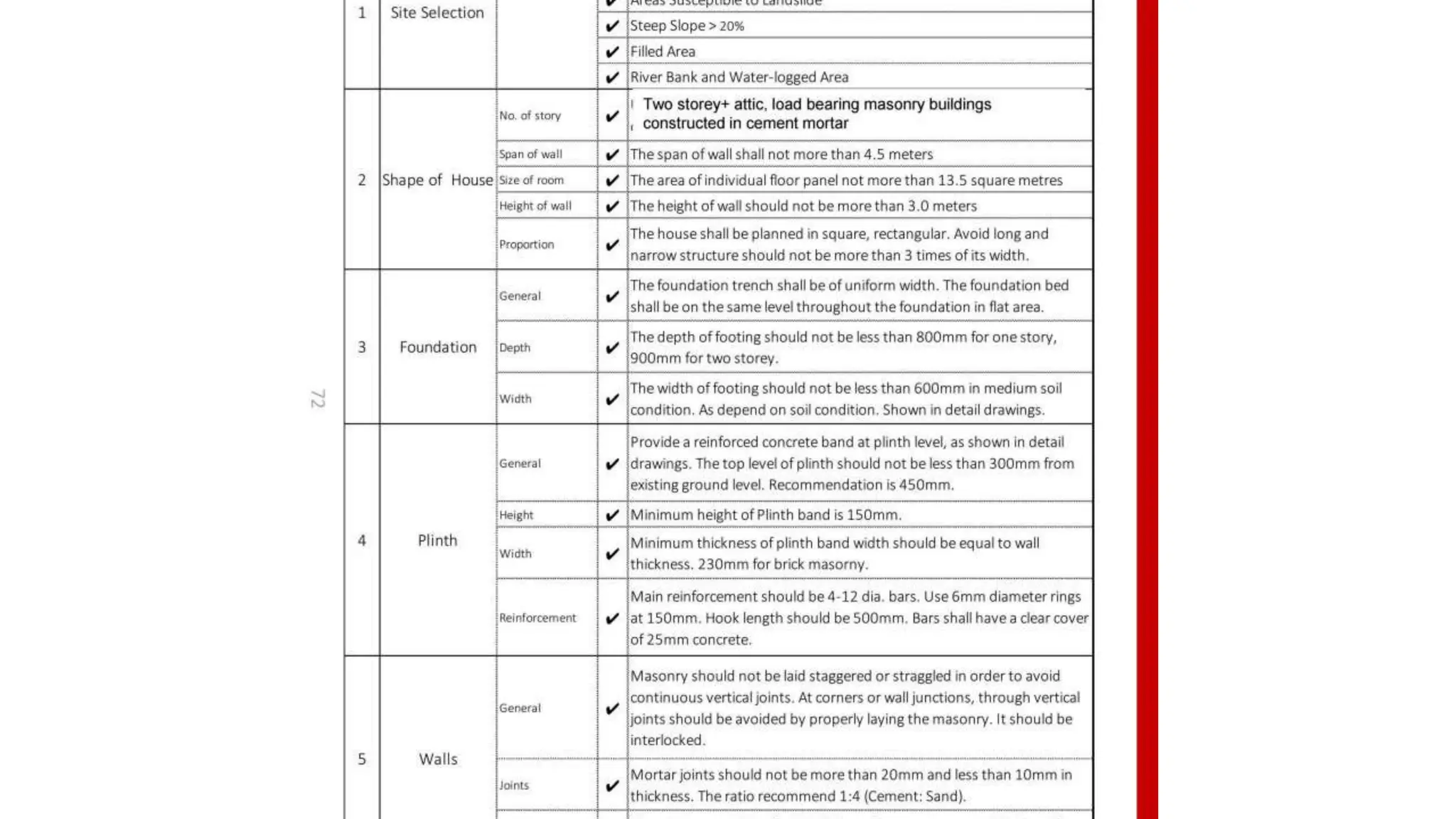

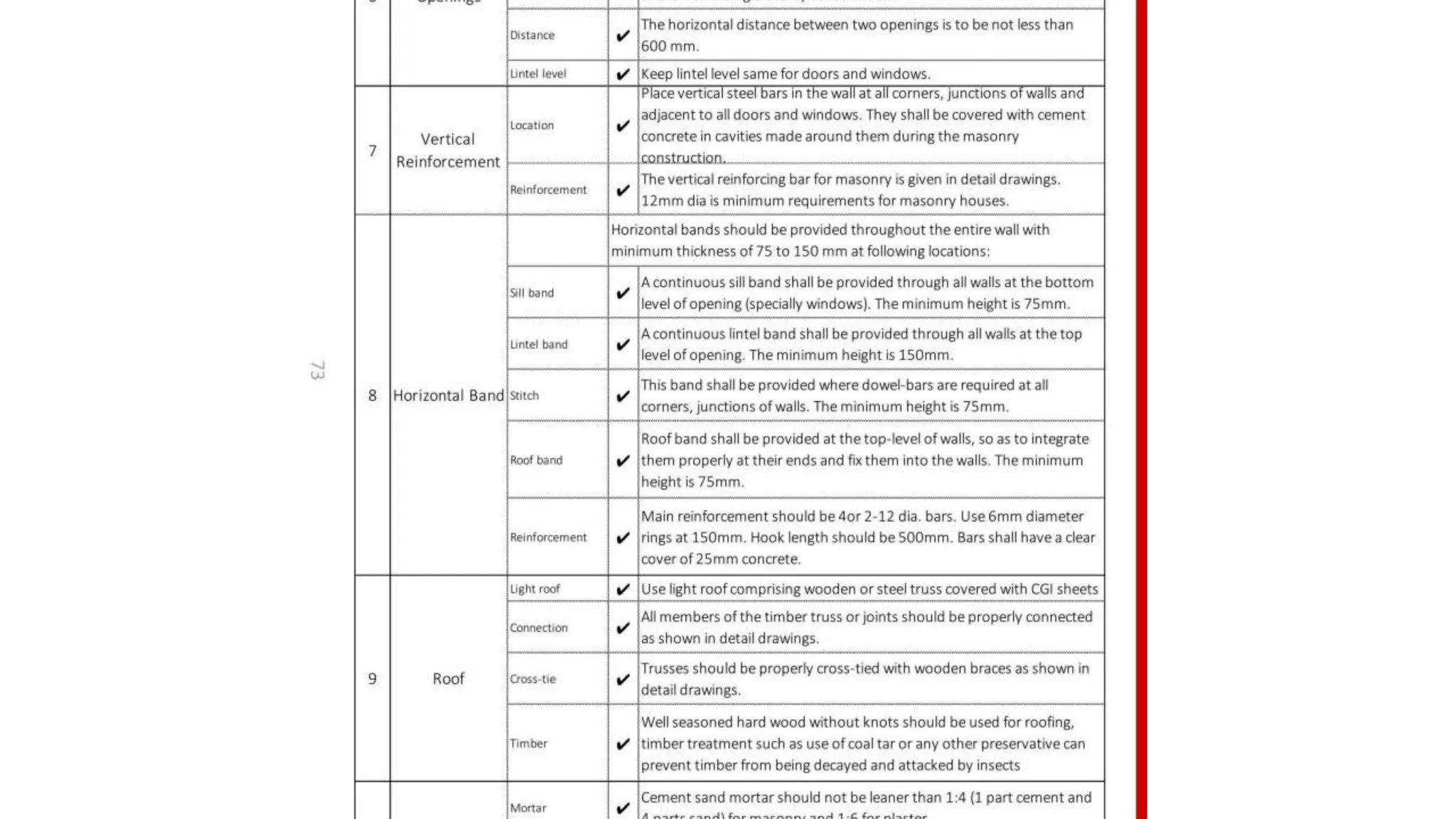

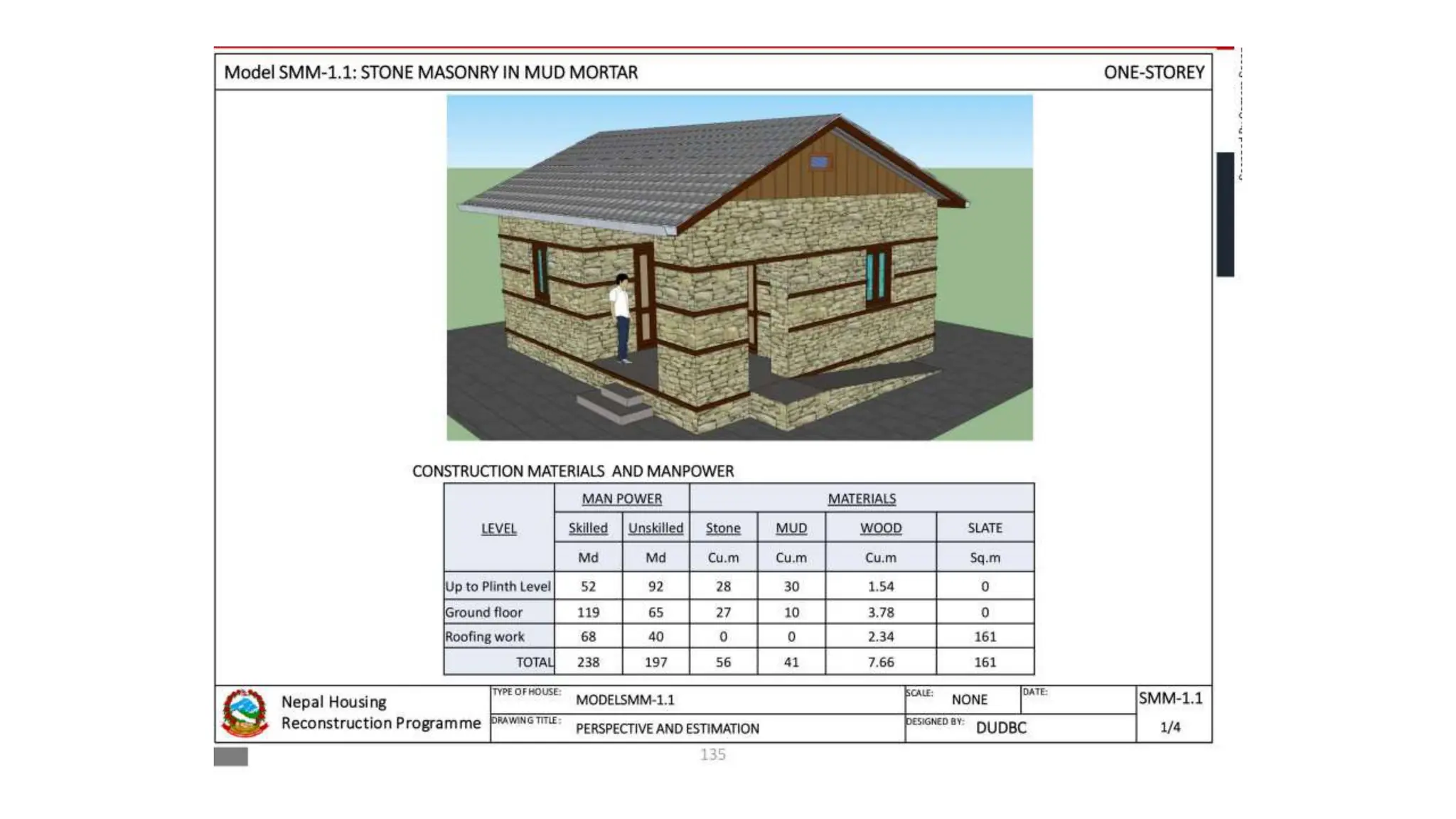

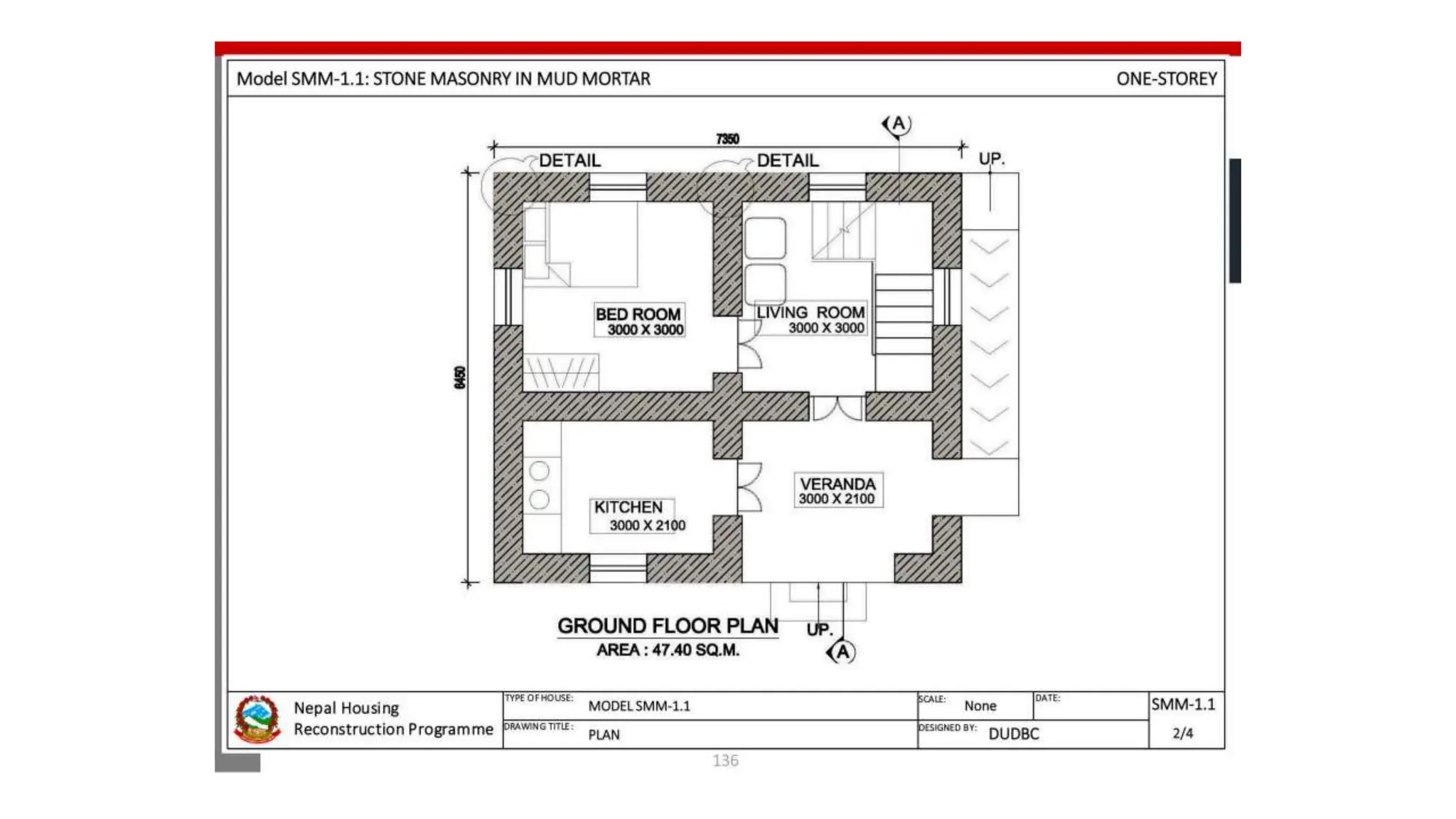

The document discusses masonry construction, focusing on types of stone masonry and their characteristics, particularly in rural Nepal. Five types of stone masonry, including rubble and ashlar masonry, are described along with construction requirements and comparisons to brick masonry. It highlights the durability, cost, and usage differences between stone and brick masonry, concluding that while stone is more durable, brick masonry is generally more economical and easier to work with.