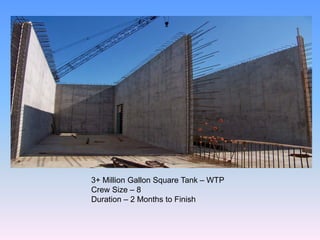

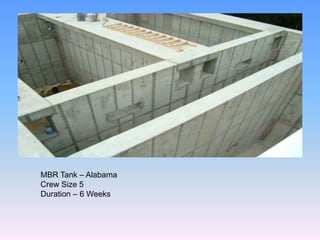

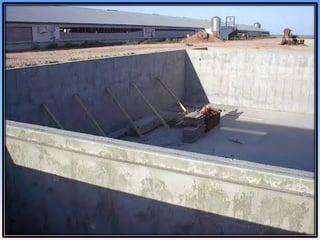

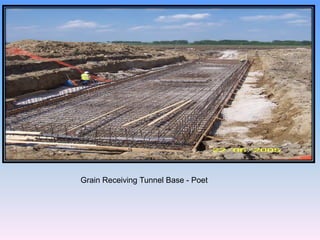

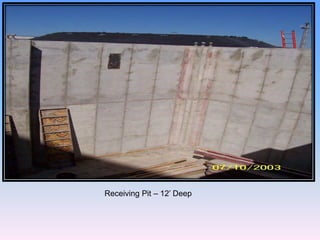

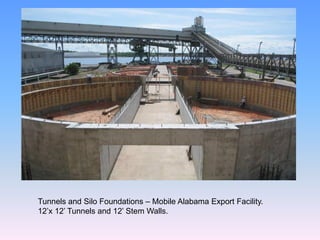

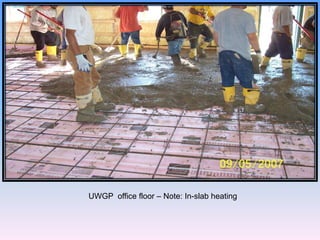

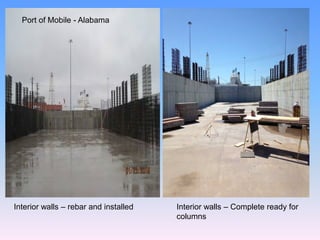

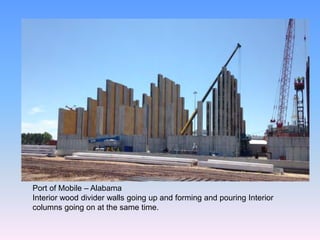

Strongform is a nationwide general contractor that specializes in industrial structural concrete construction including rebar placement, steel buildings, and structural steel erection. It serves various industries such as alternative energy, agriculture, mining, cement, fertilizer, food and beverage, and power. Strongform performs work on aggressive schedules and maintains high safety standards. It offers services for expansions and new construction projects across the country.