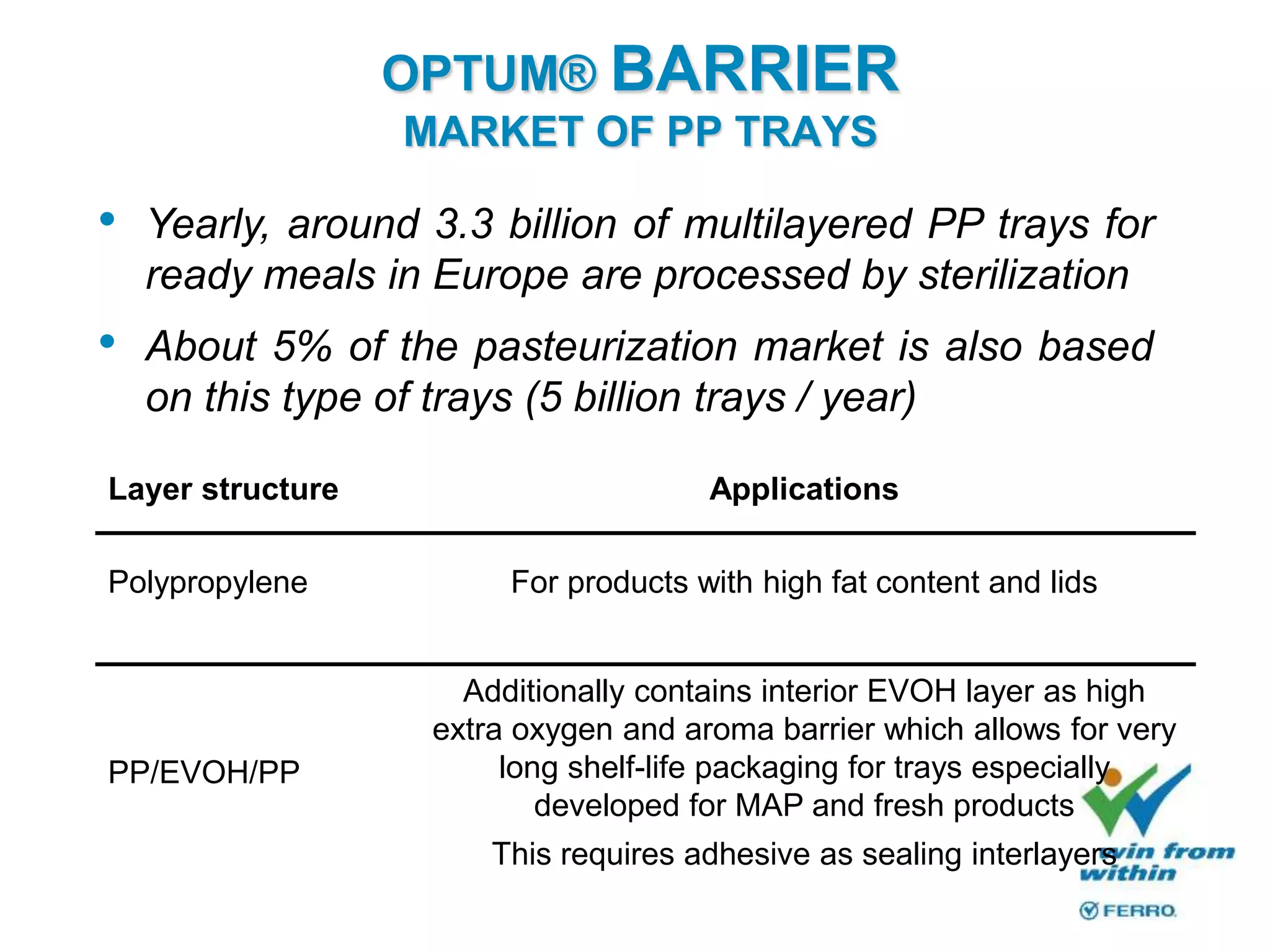

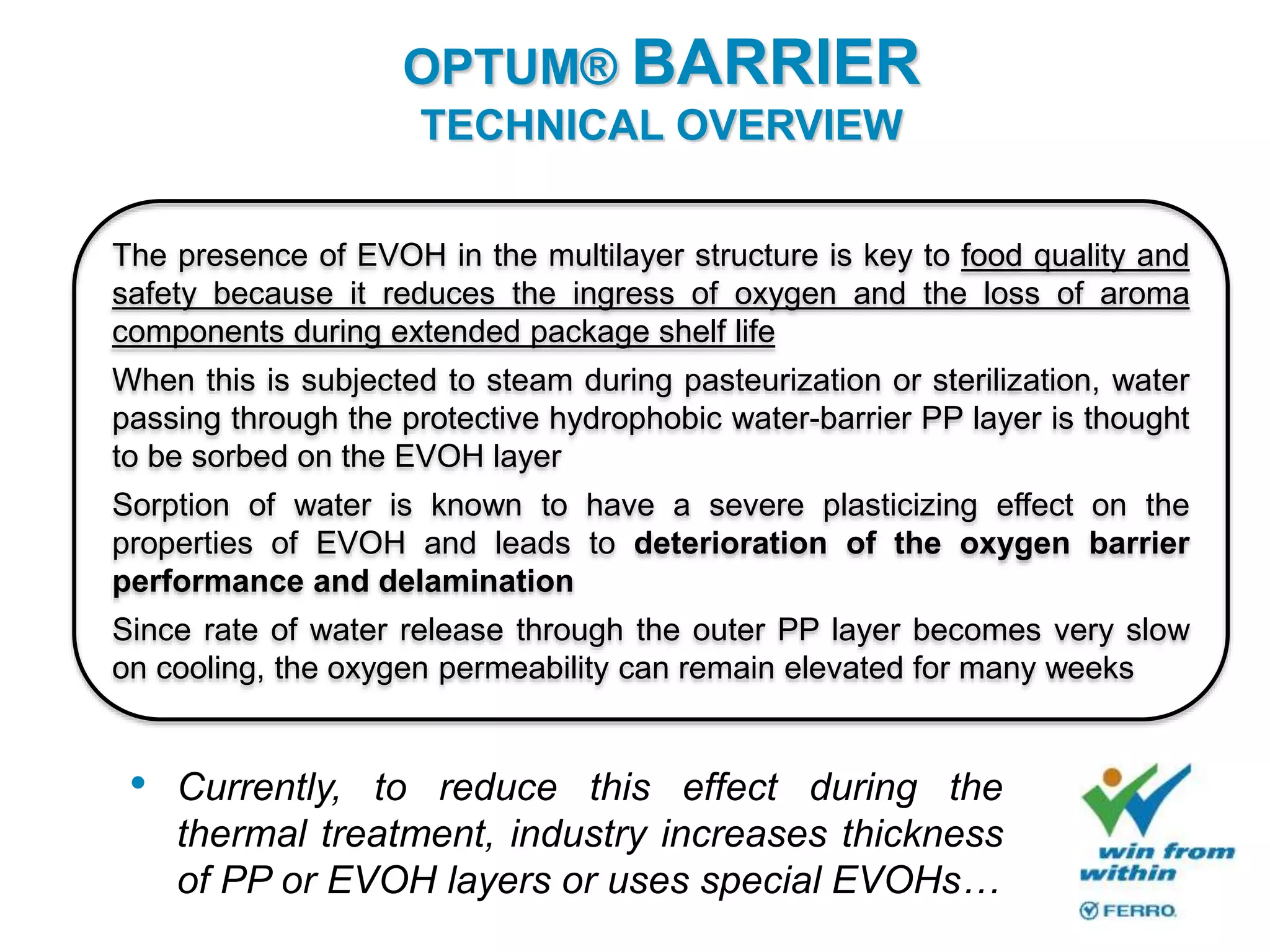

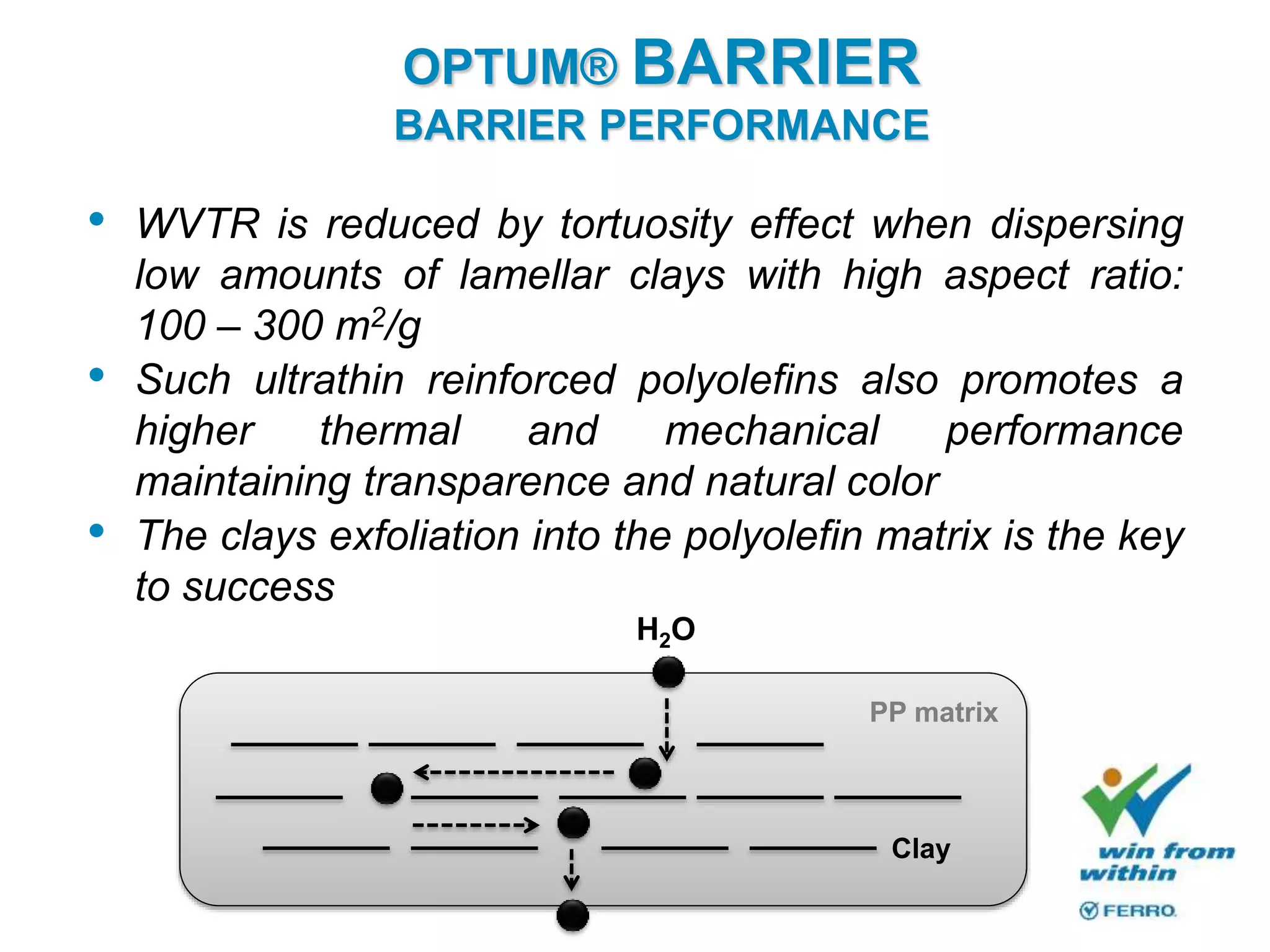

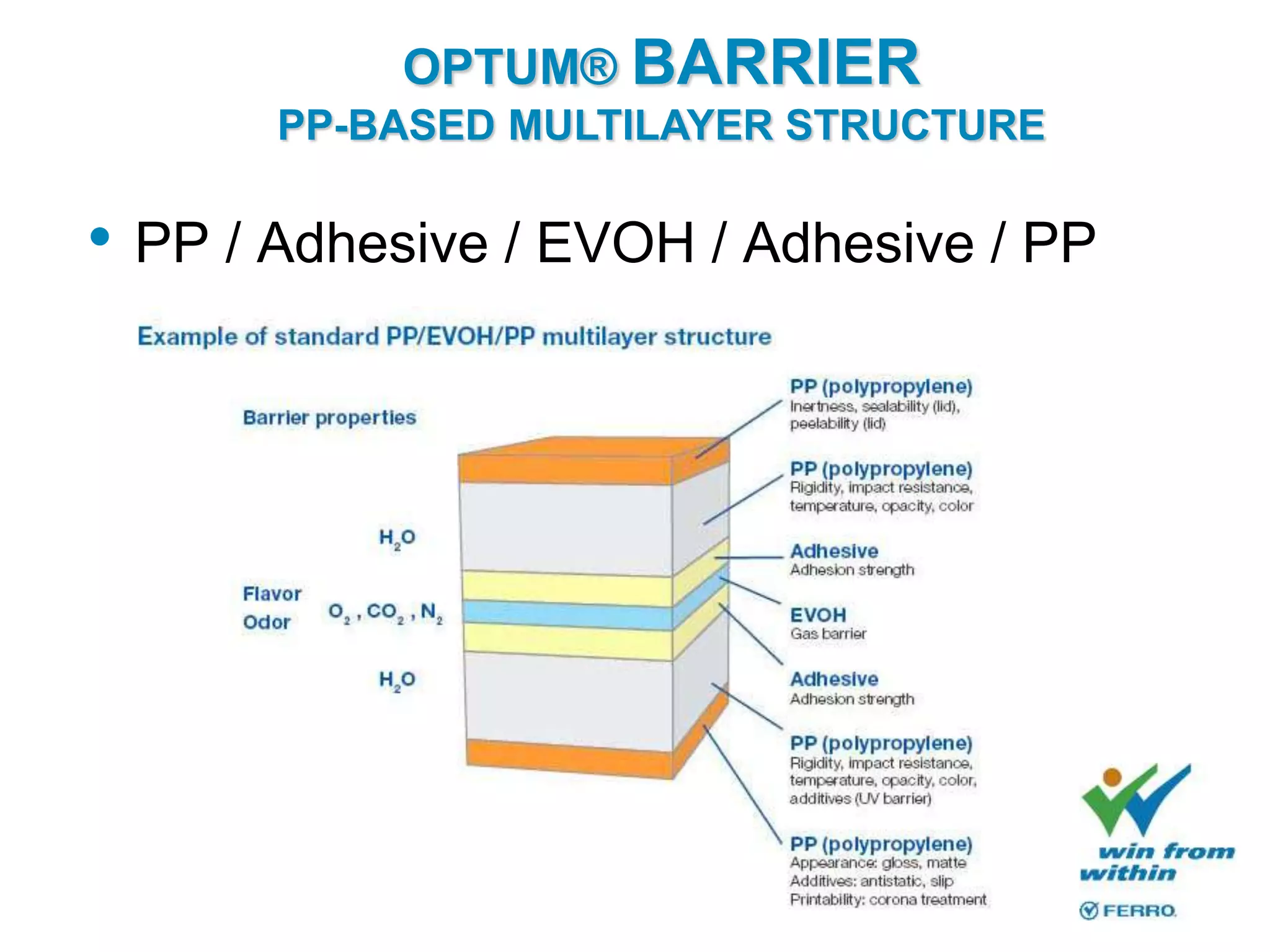

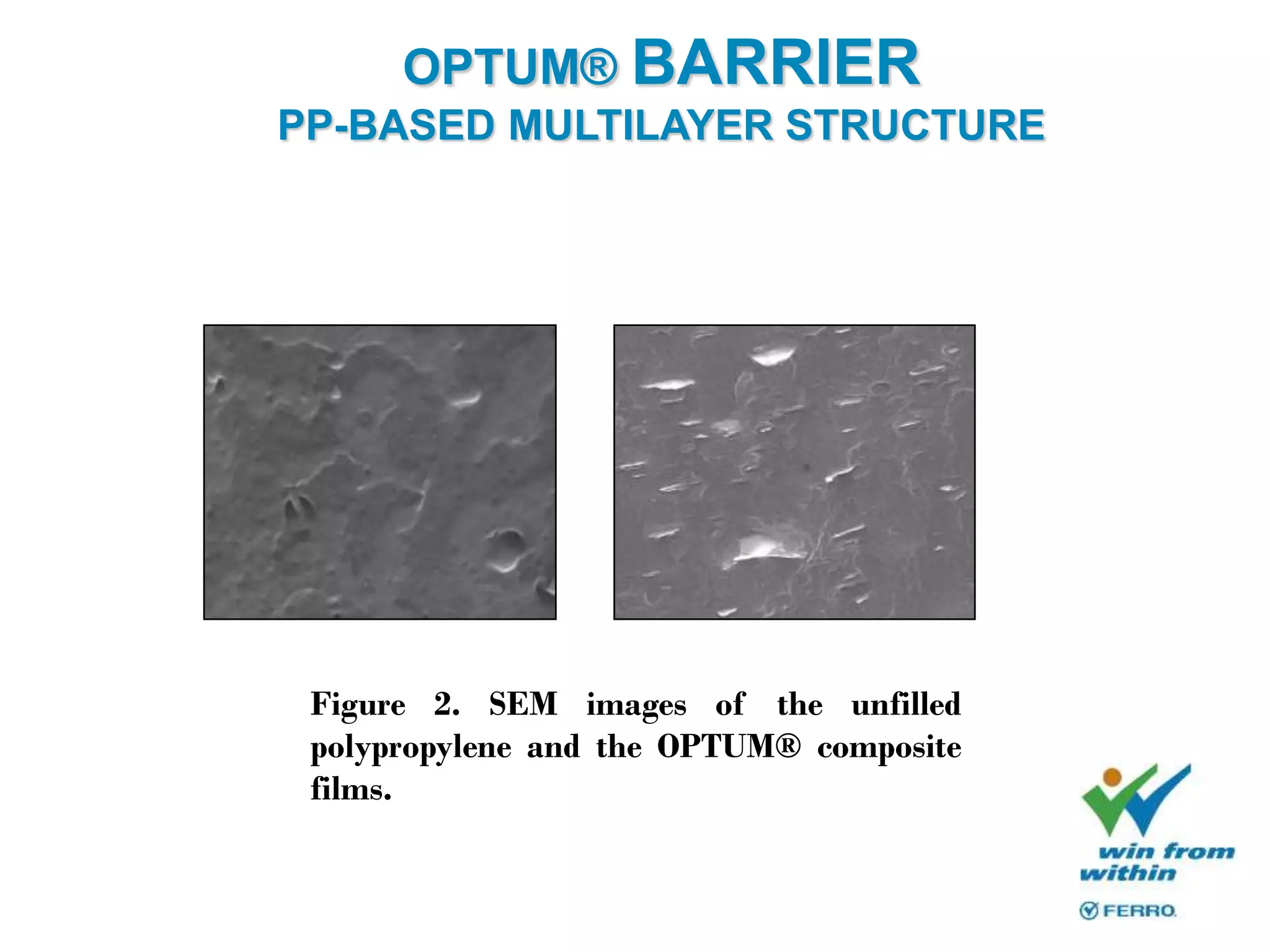

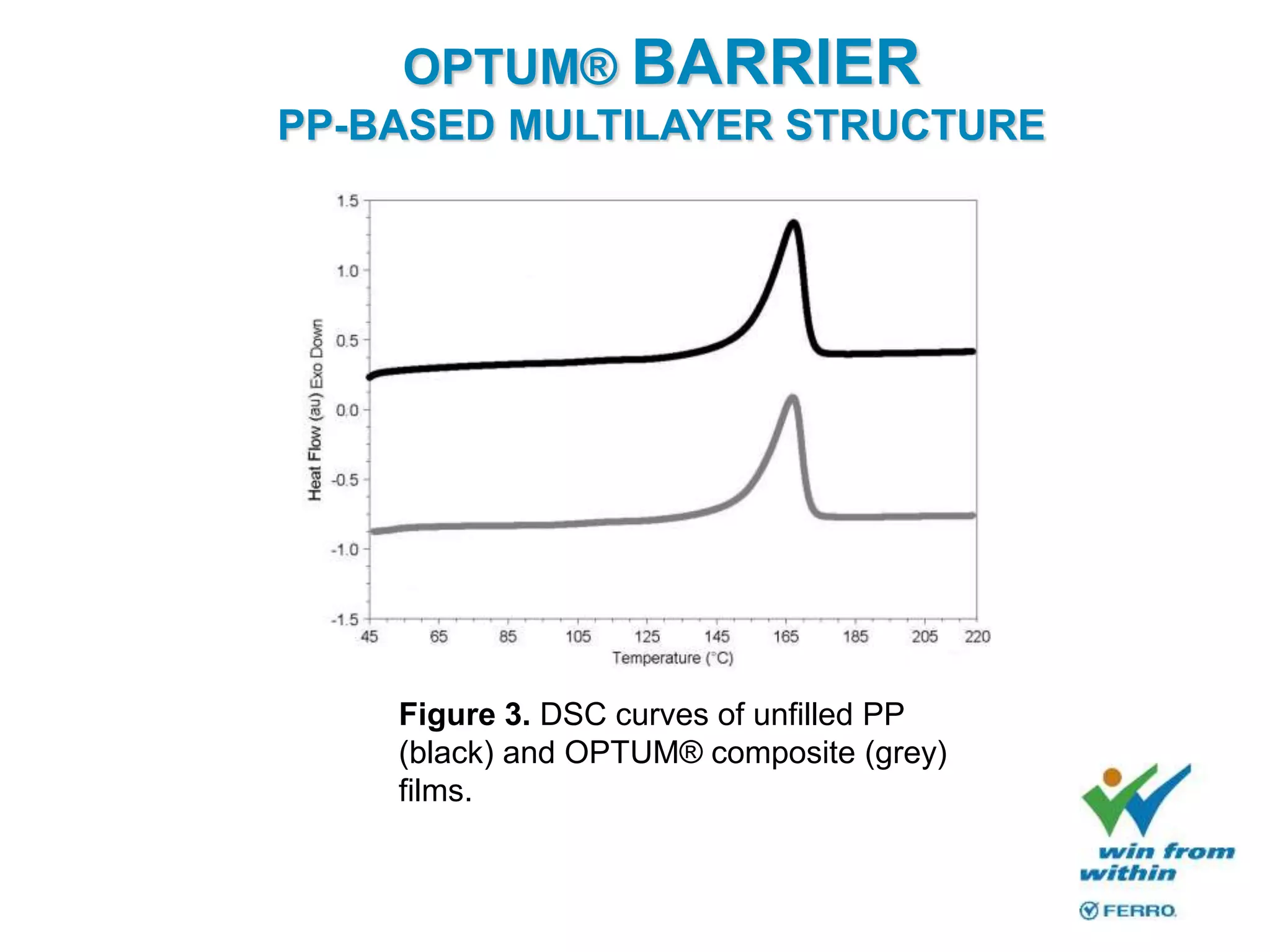

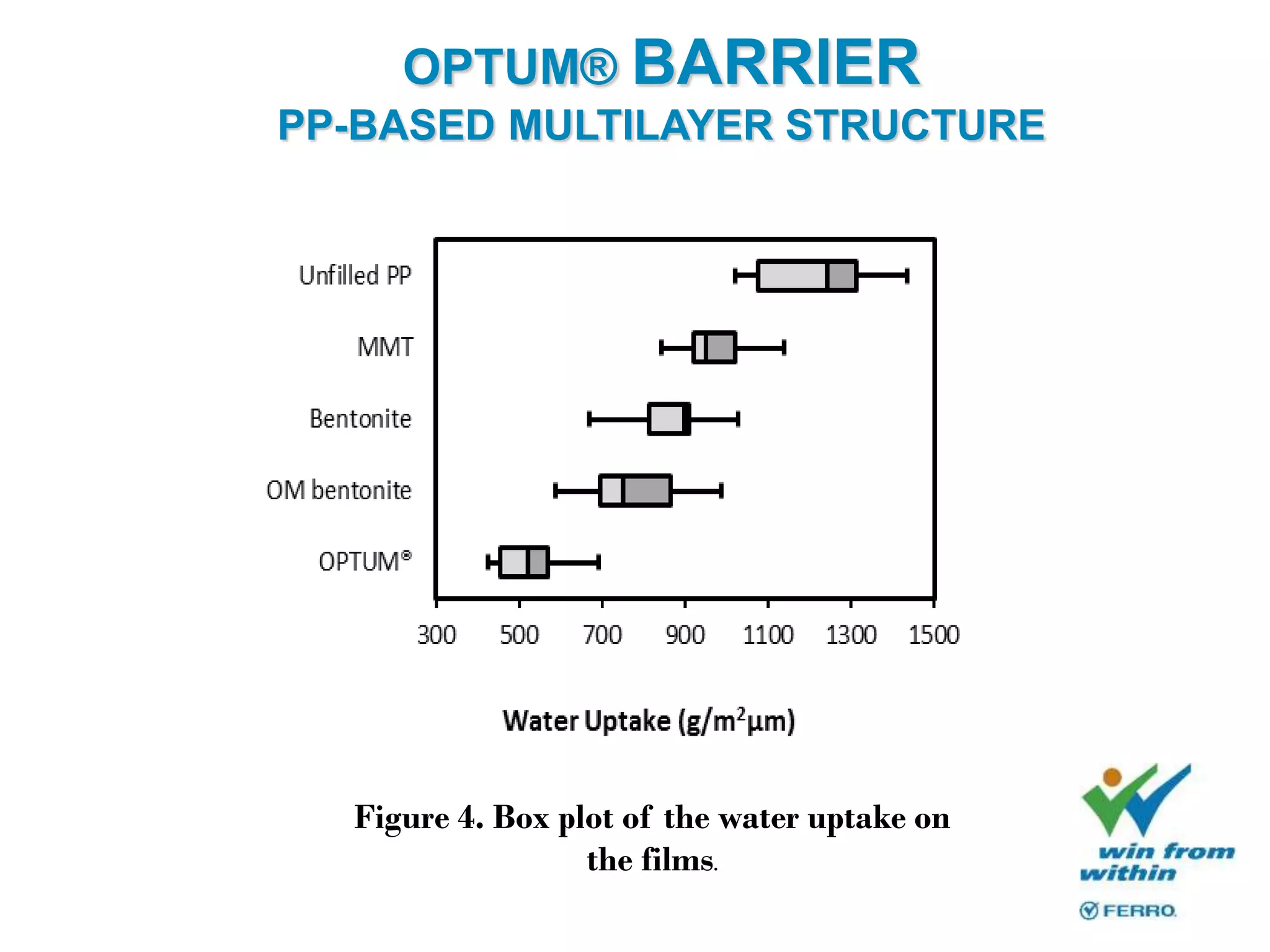

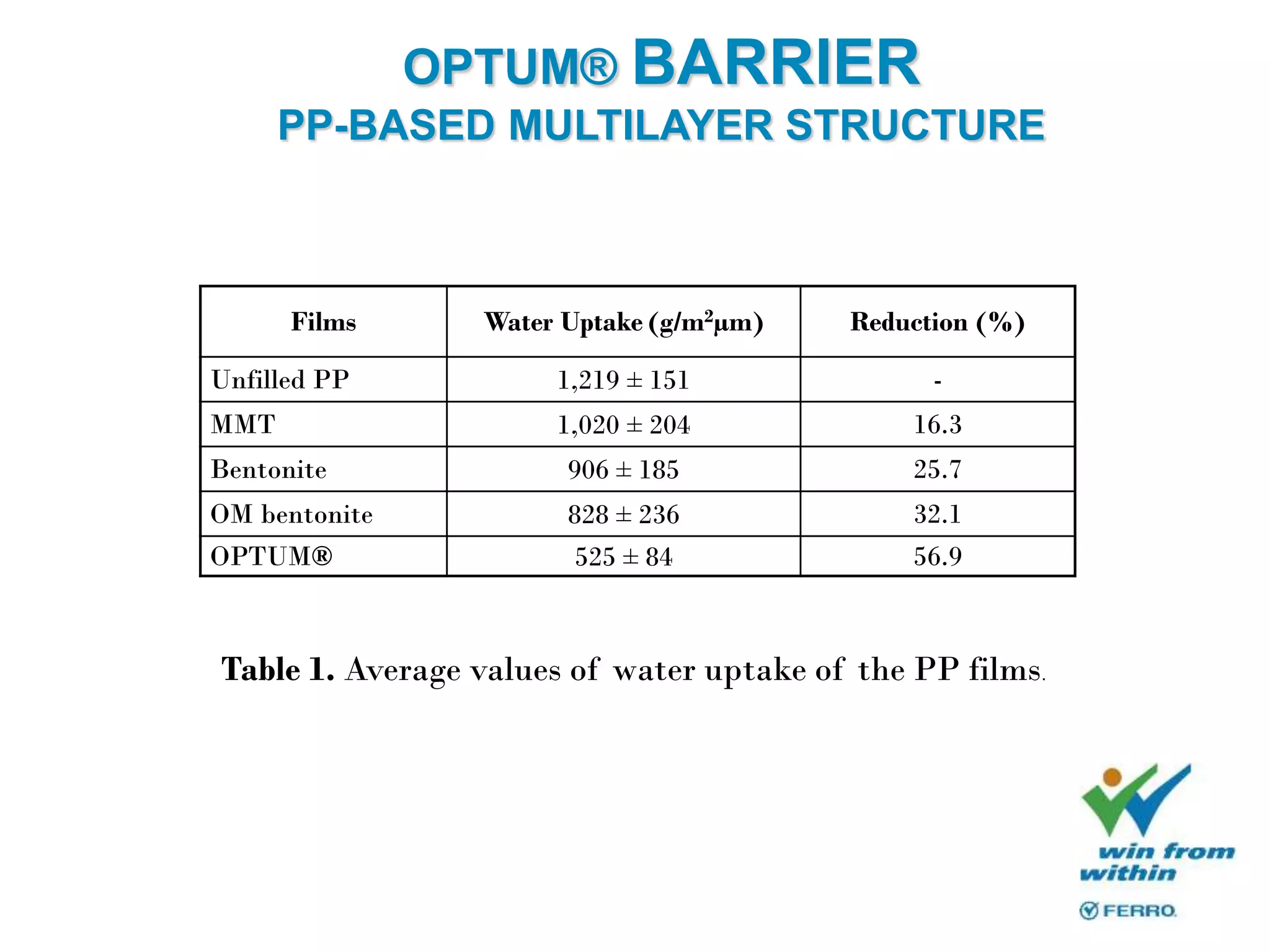

Dr. José Luis Feijoo-Gómez presented at the SPE Polyolefins Conference in February 2014 in Houston. He discussed OPTUM®, an innovative masterbatch technology from Ferro that uses non-nanosized lamellar clays to reduce the water vapor transmission rate of polypropylene-based materials used in food packaging. This allows for reduced EVOH content while maintaining barrier performance, even after thermal processing like sterilization. OPTUM® was shown to decrease the water uptake of PP films by over 50% compared to unmodified PP, protecting the barrier properties of EVOH layers during packaging shelf life.