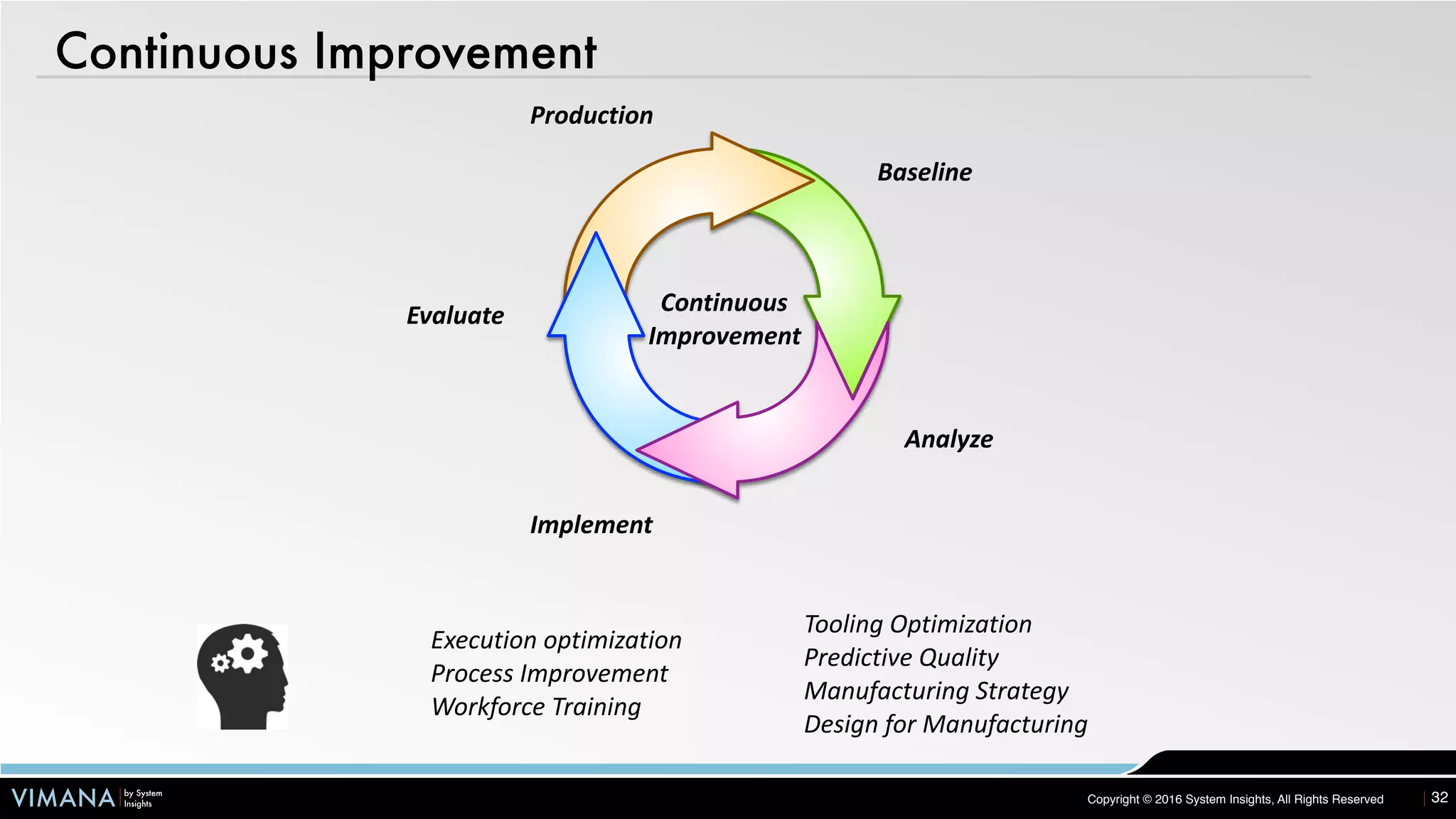

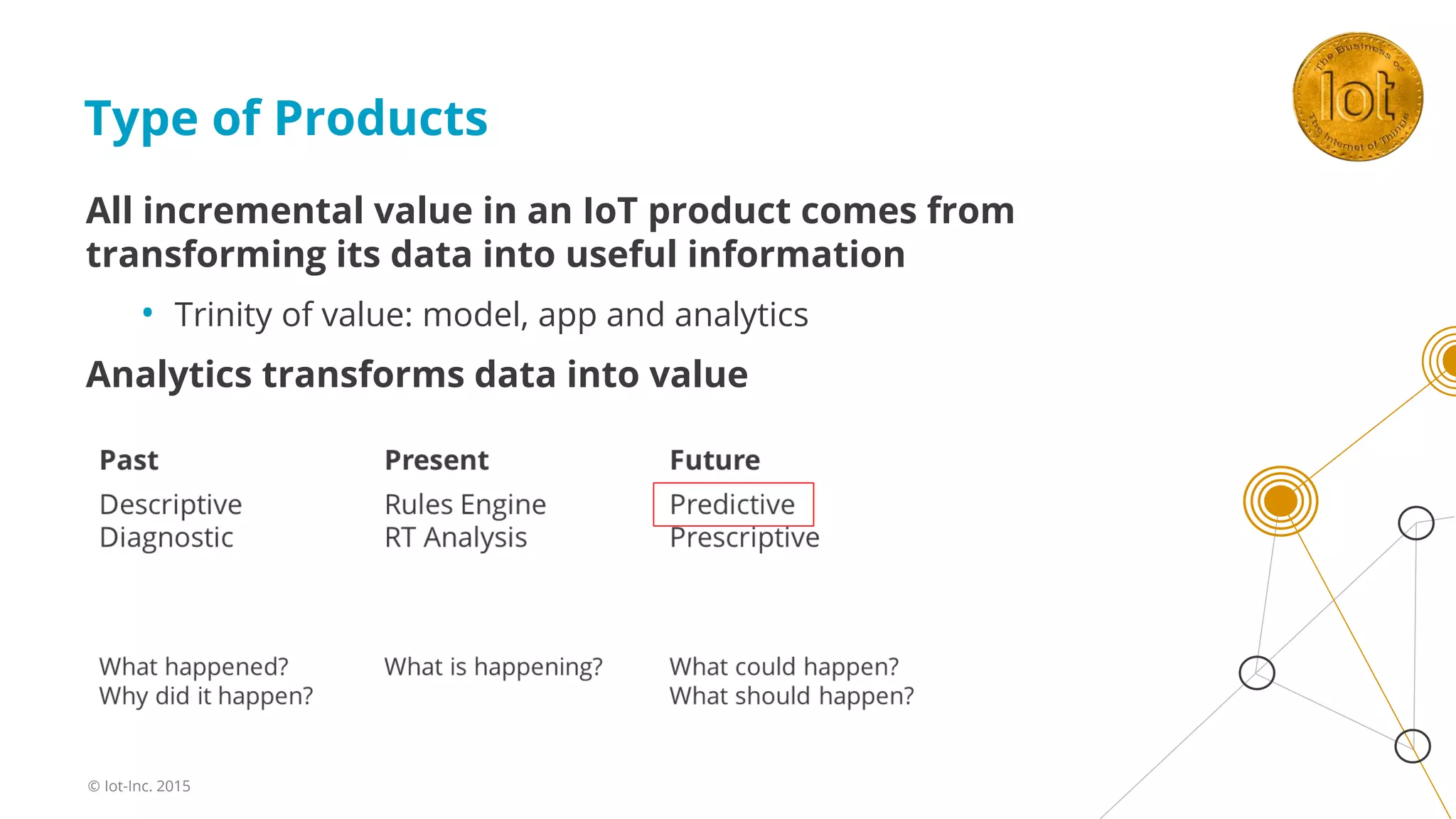

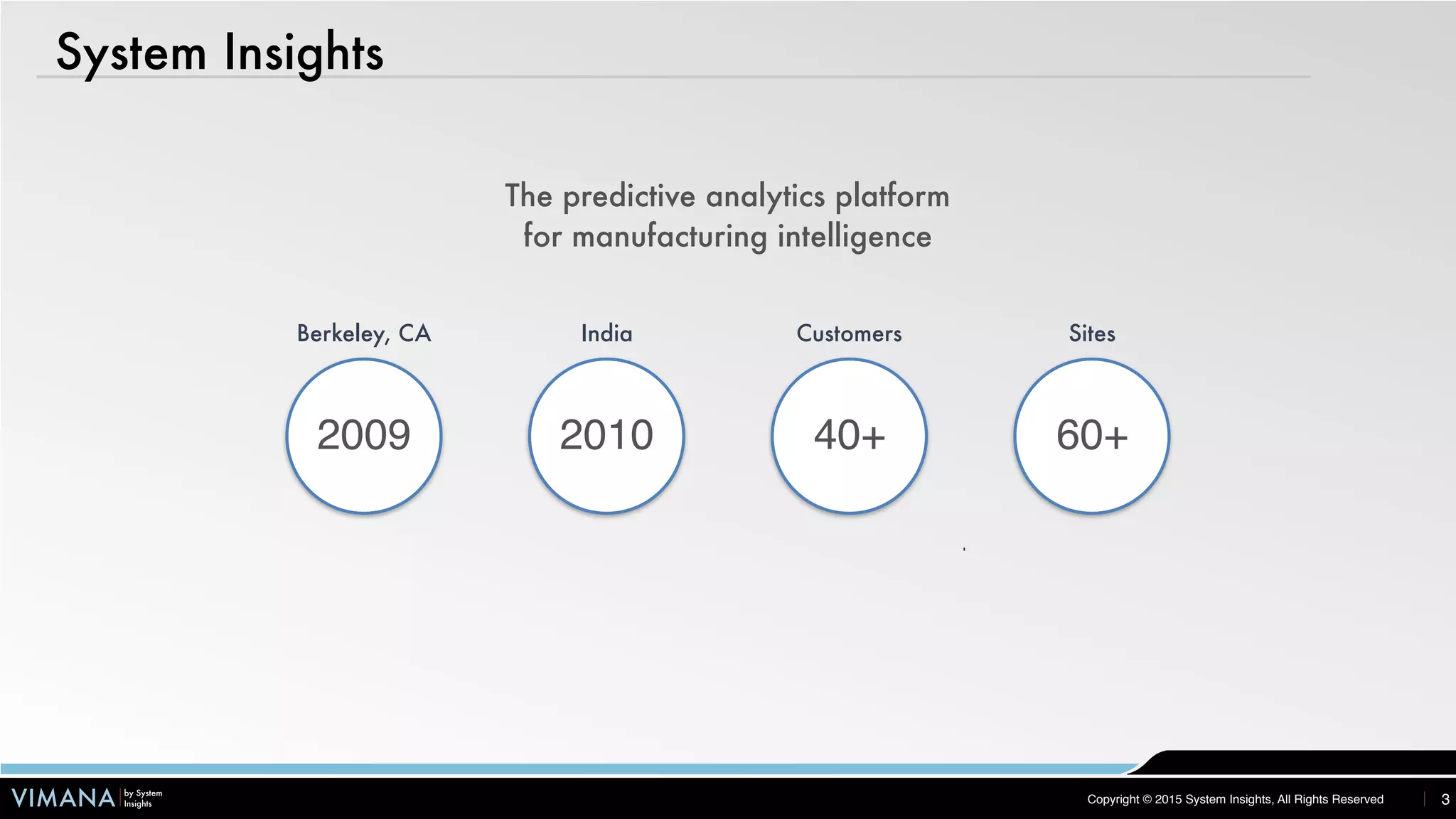

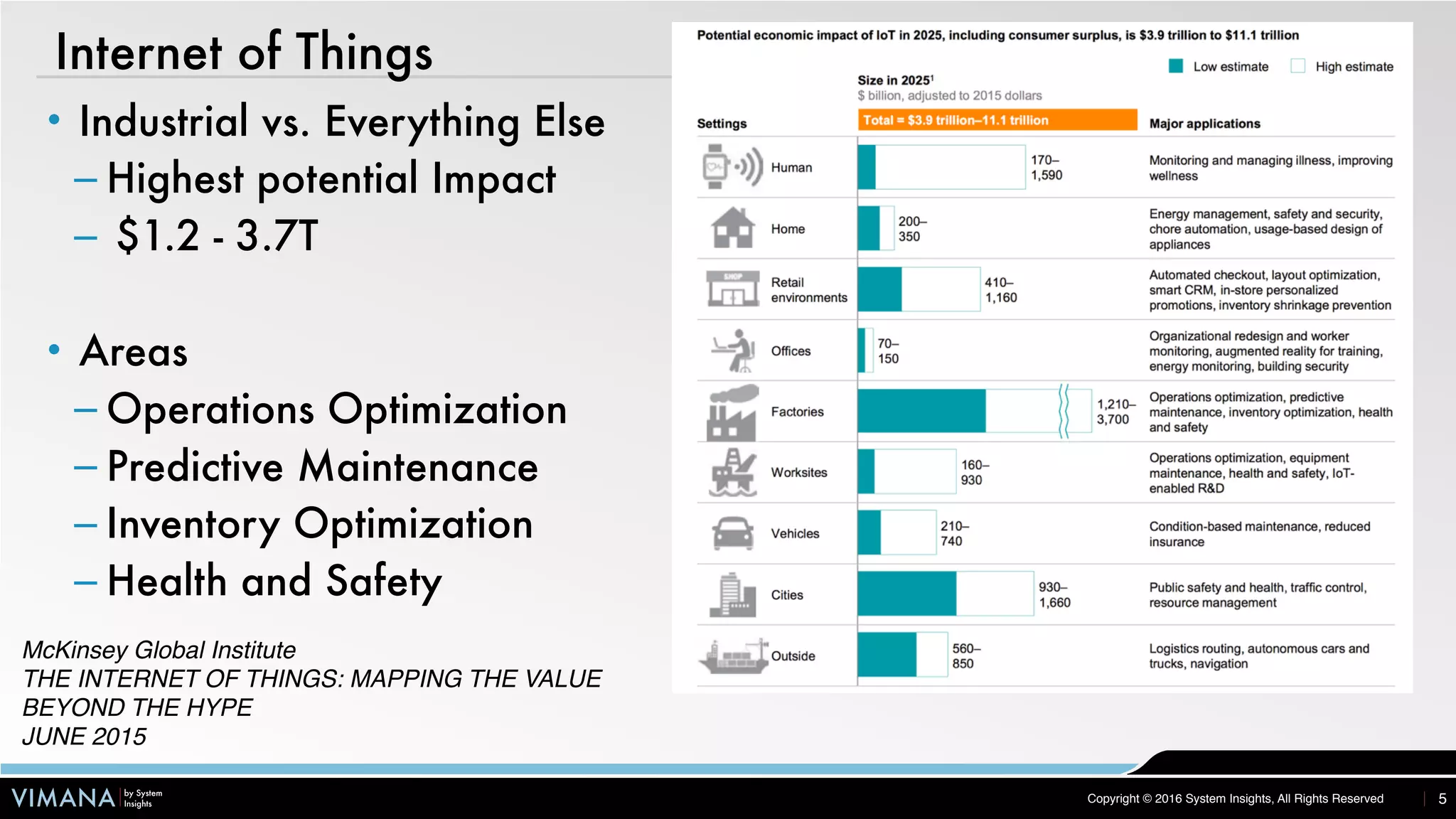

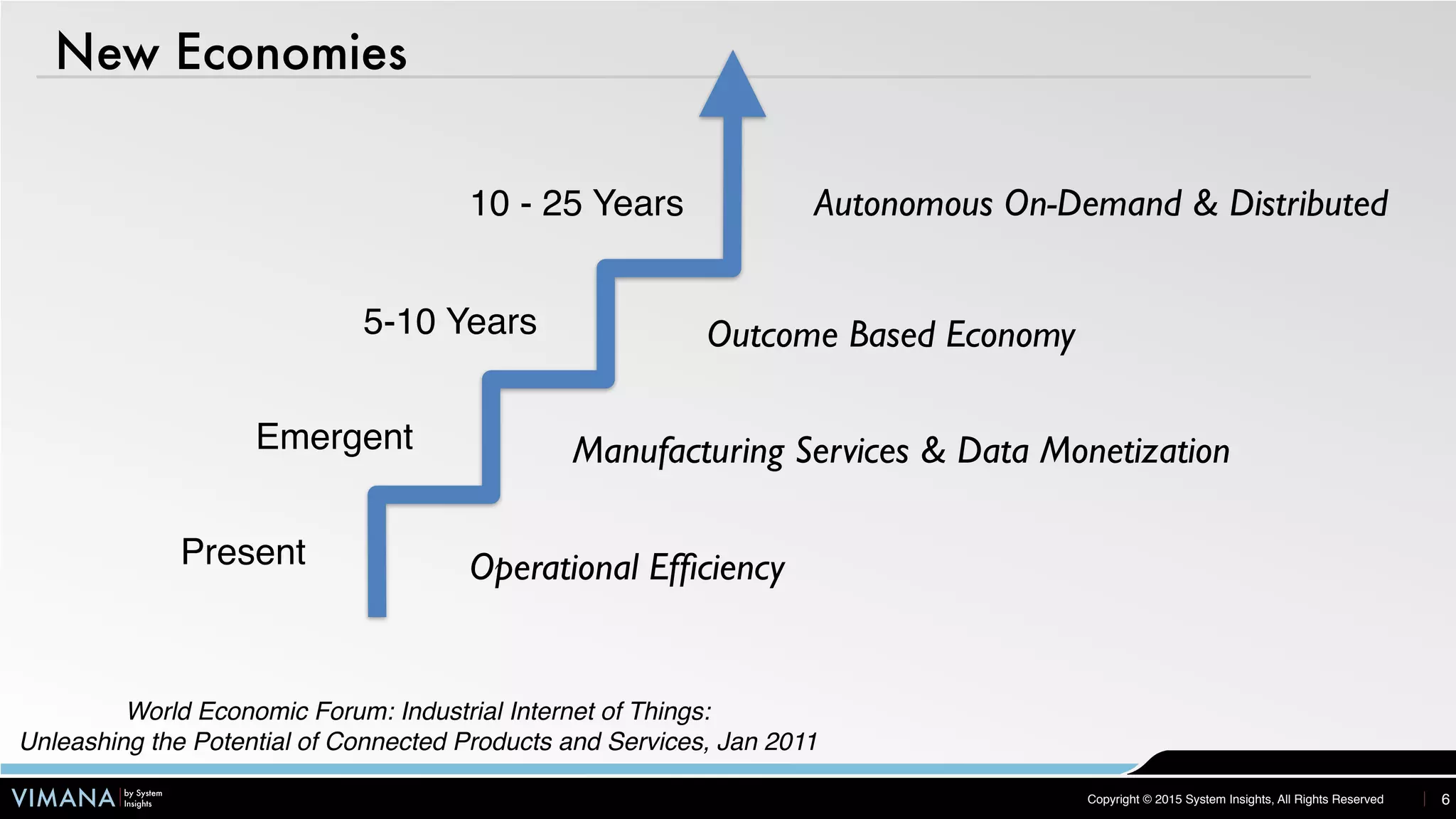

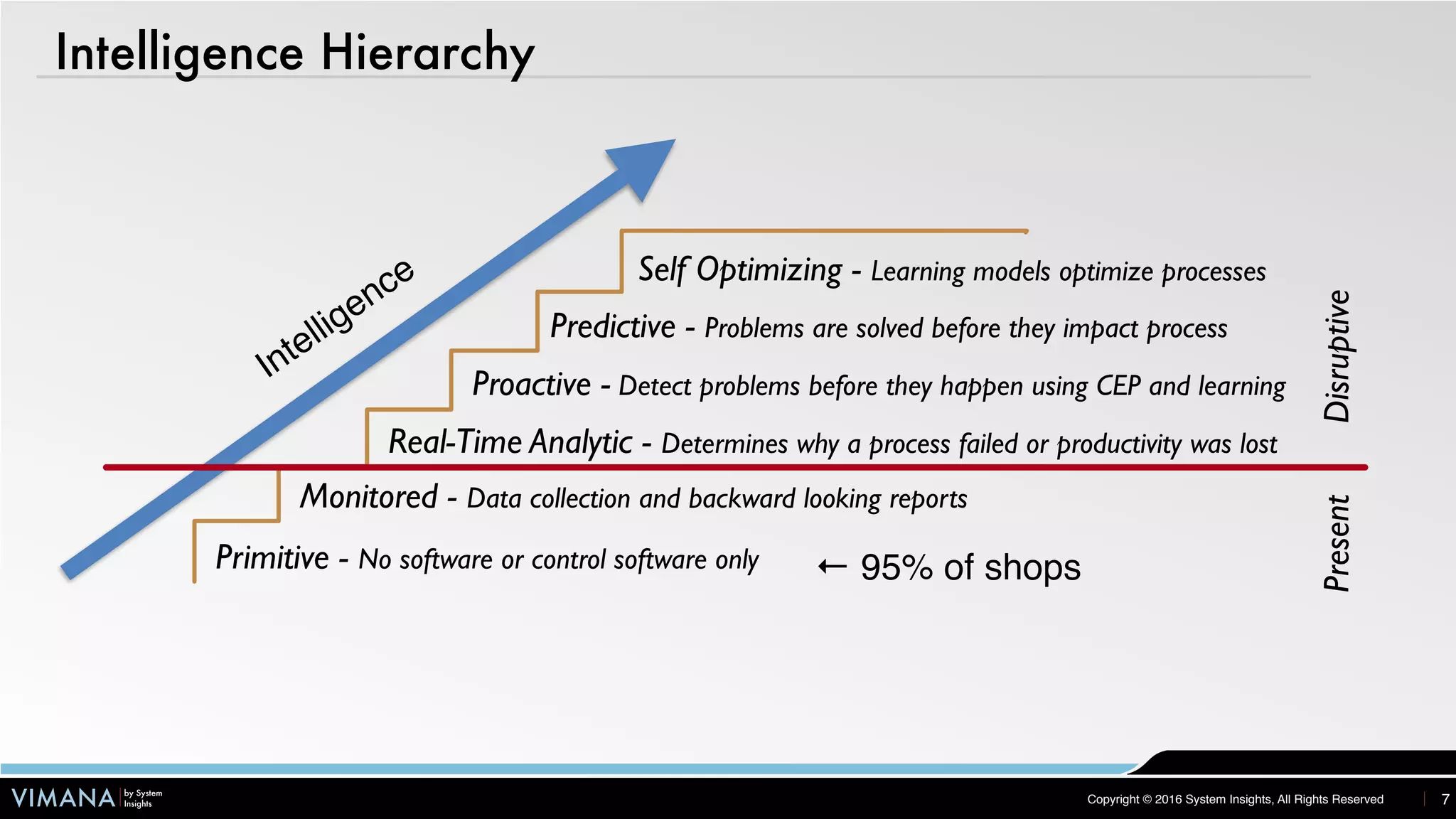

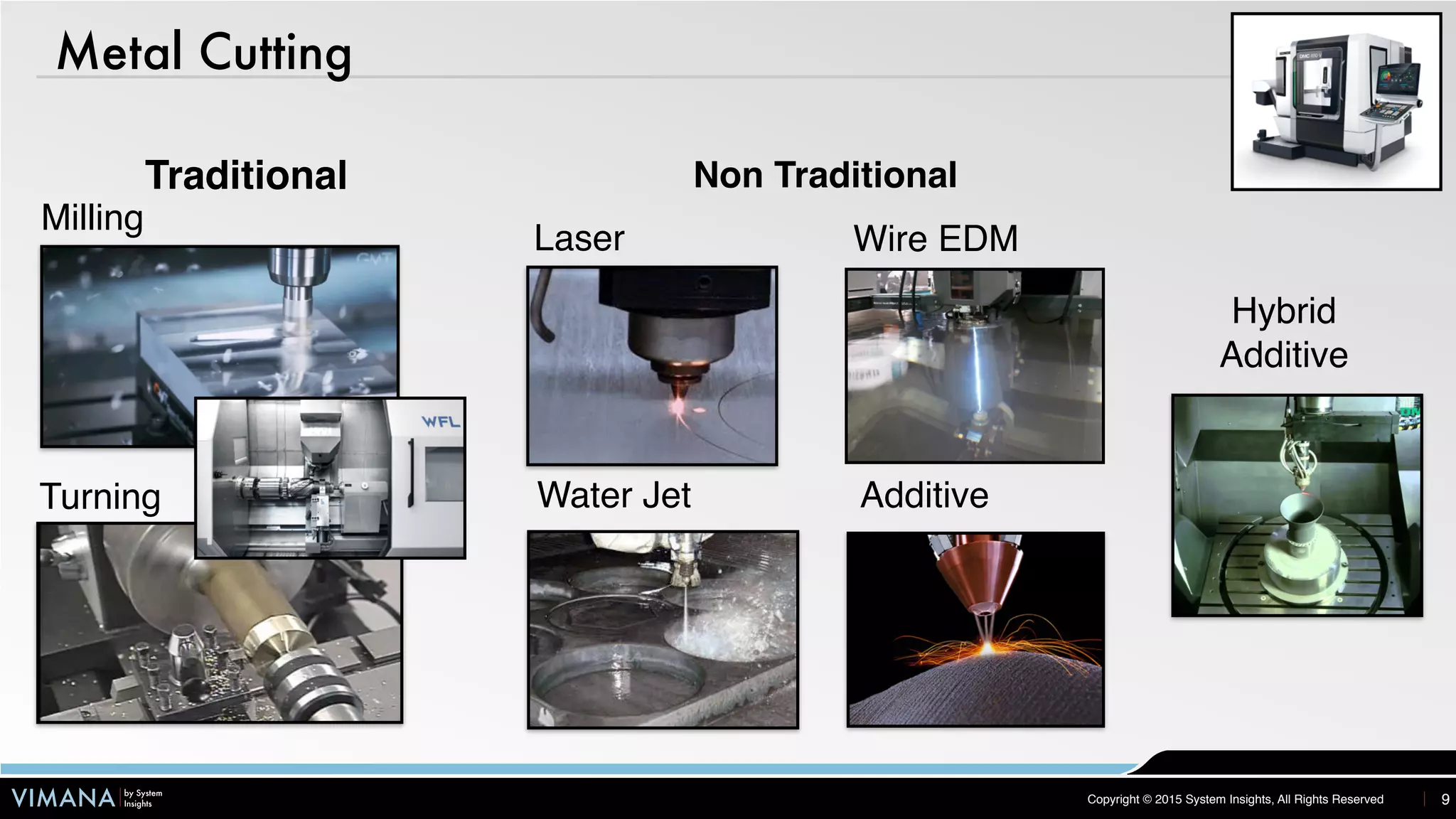

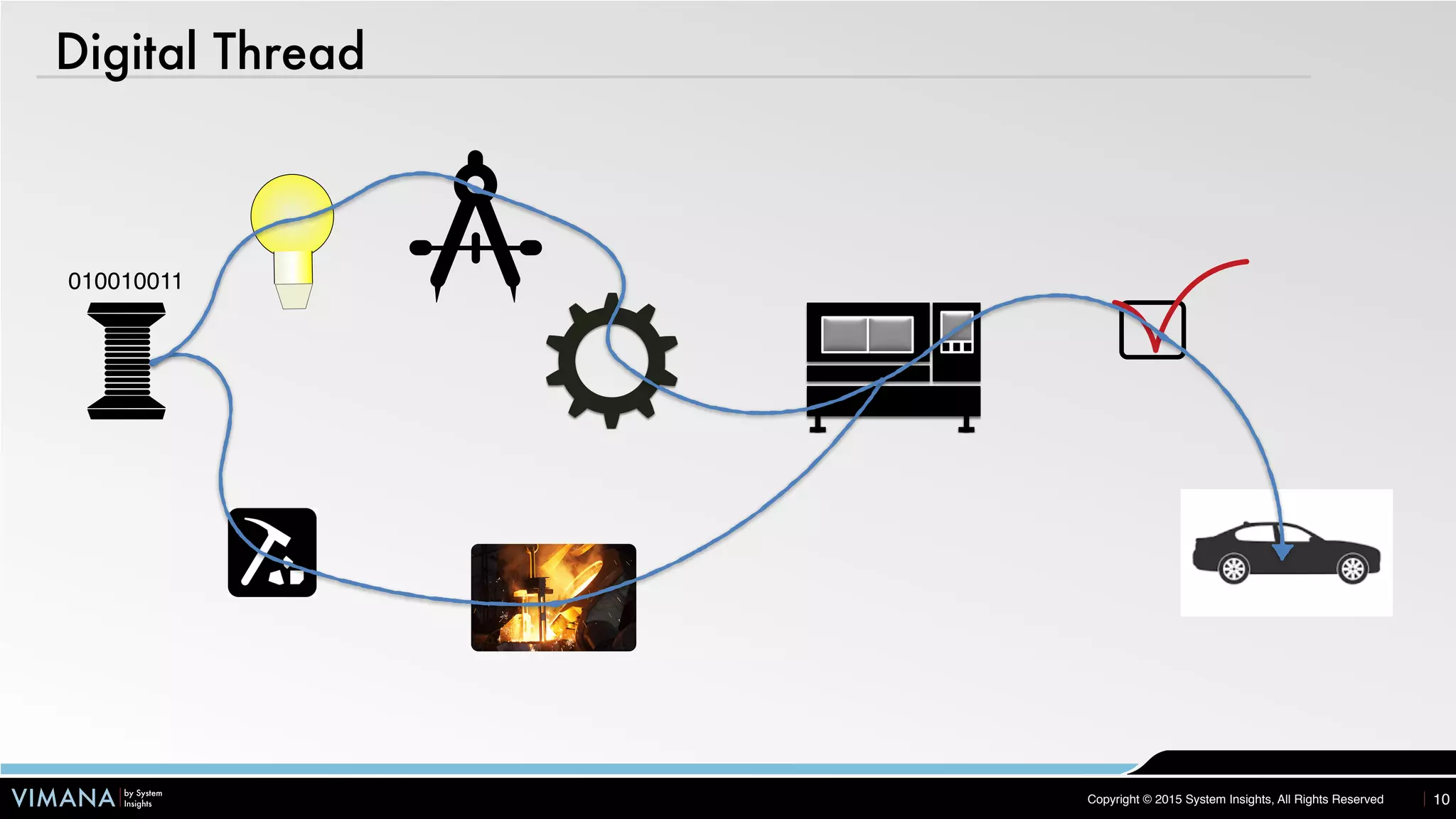

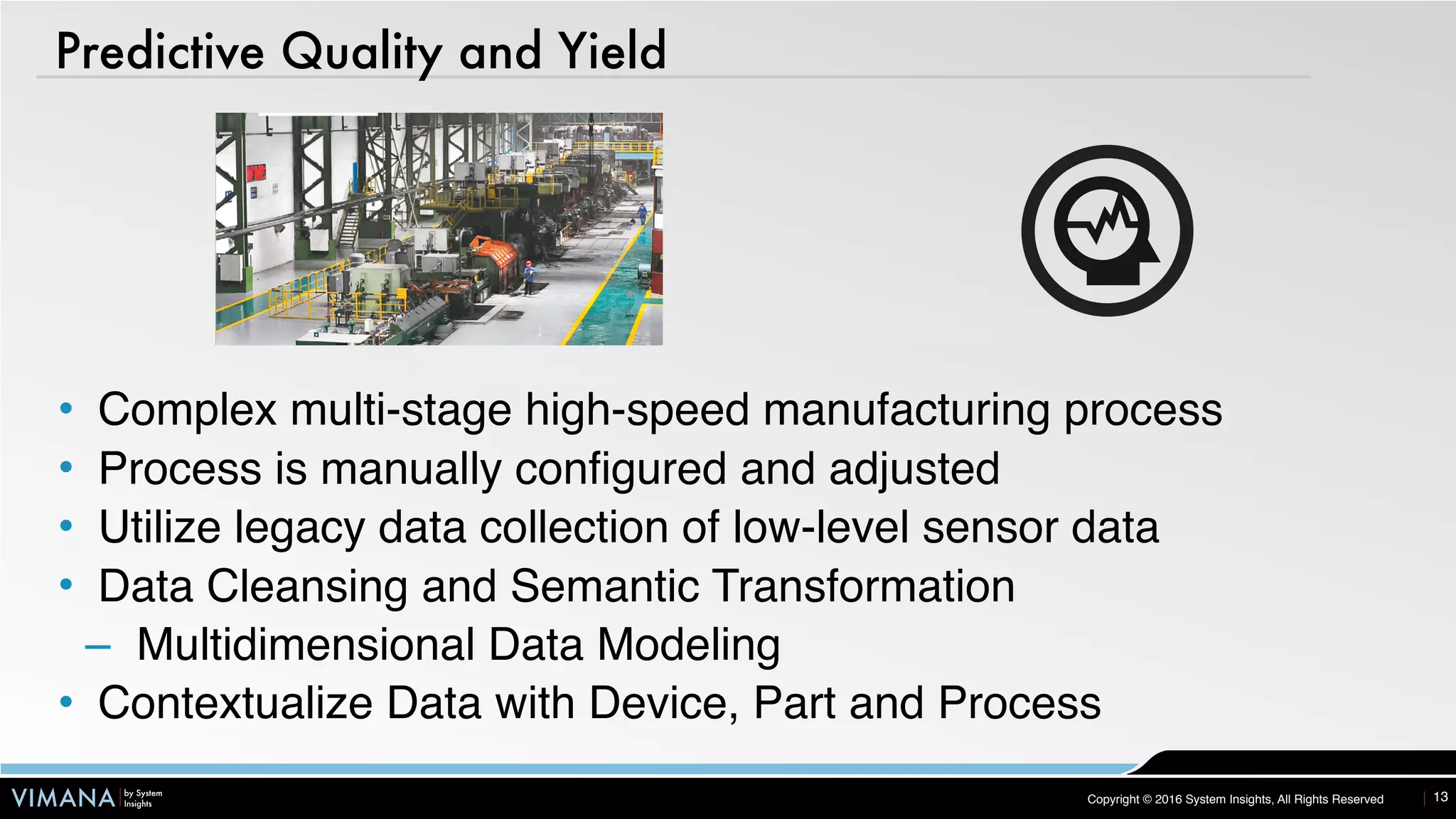

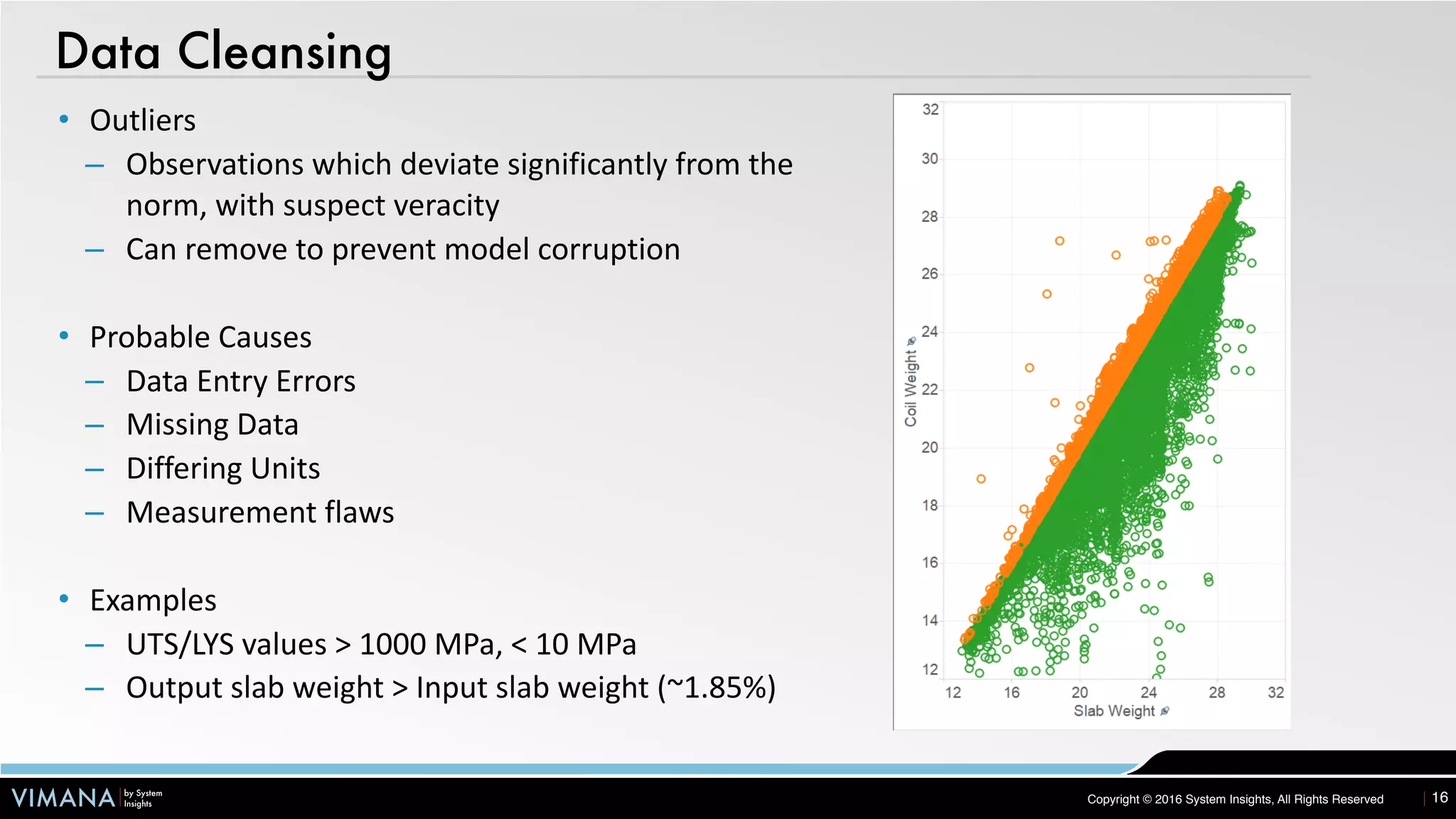

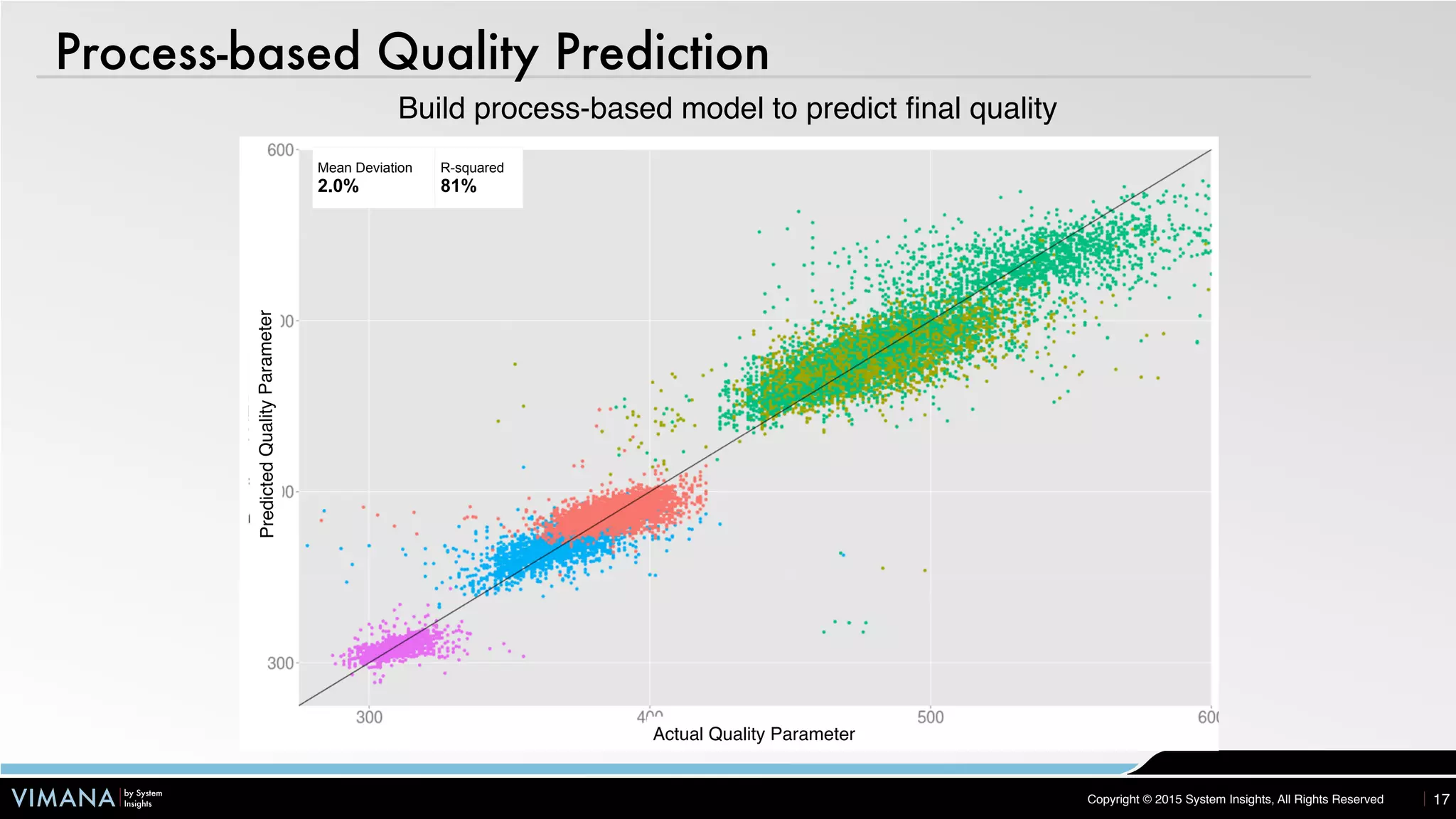

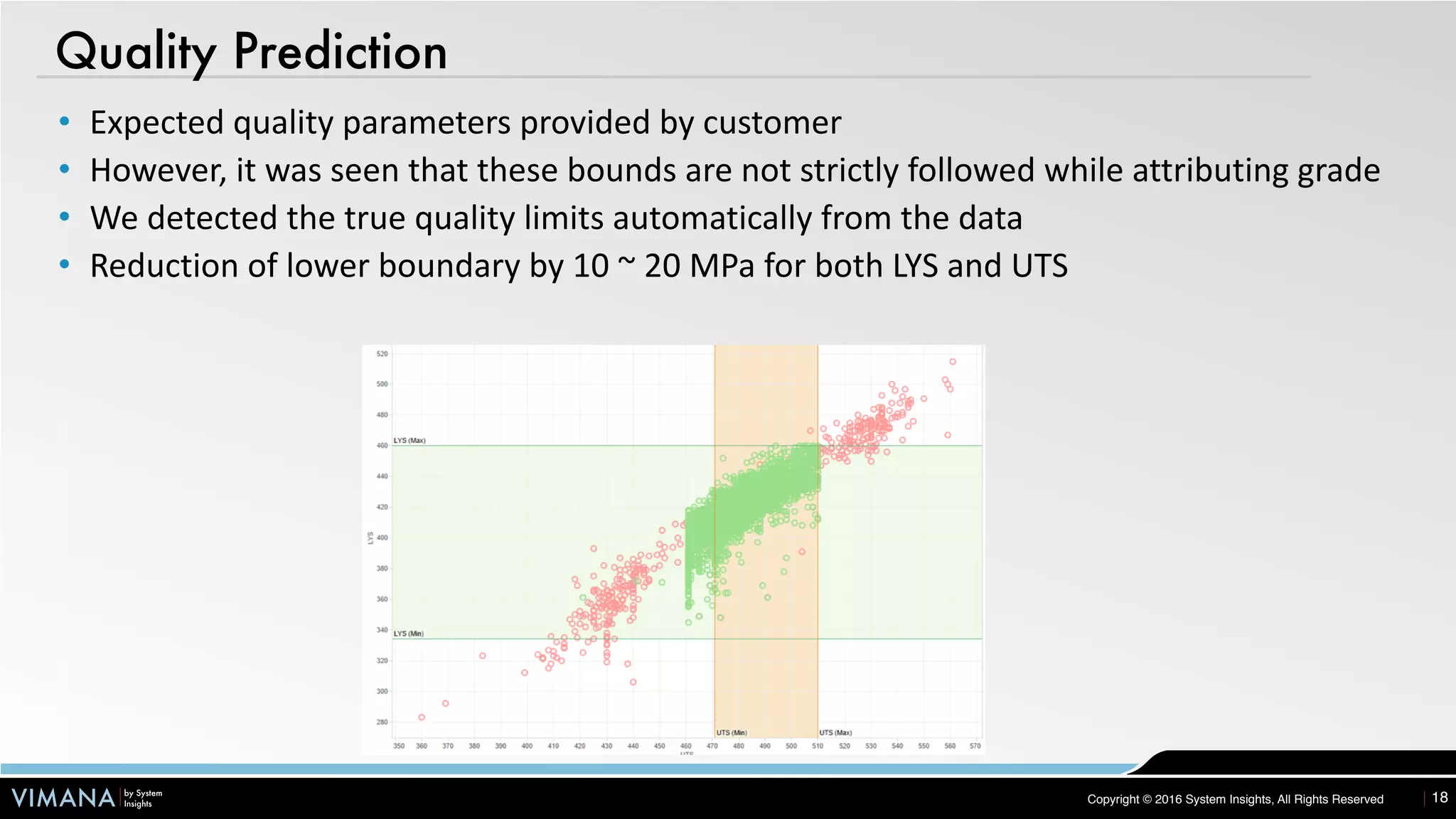

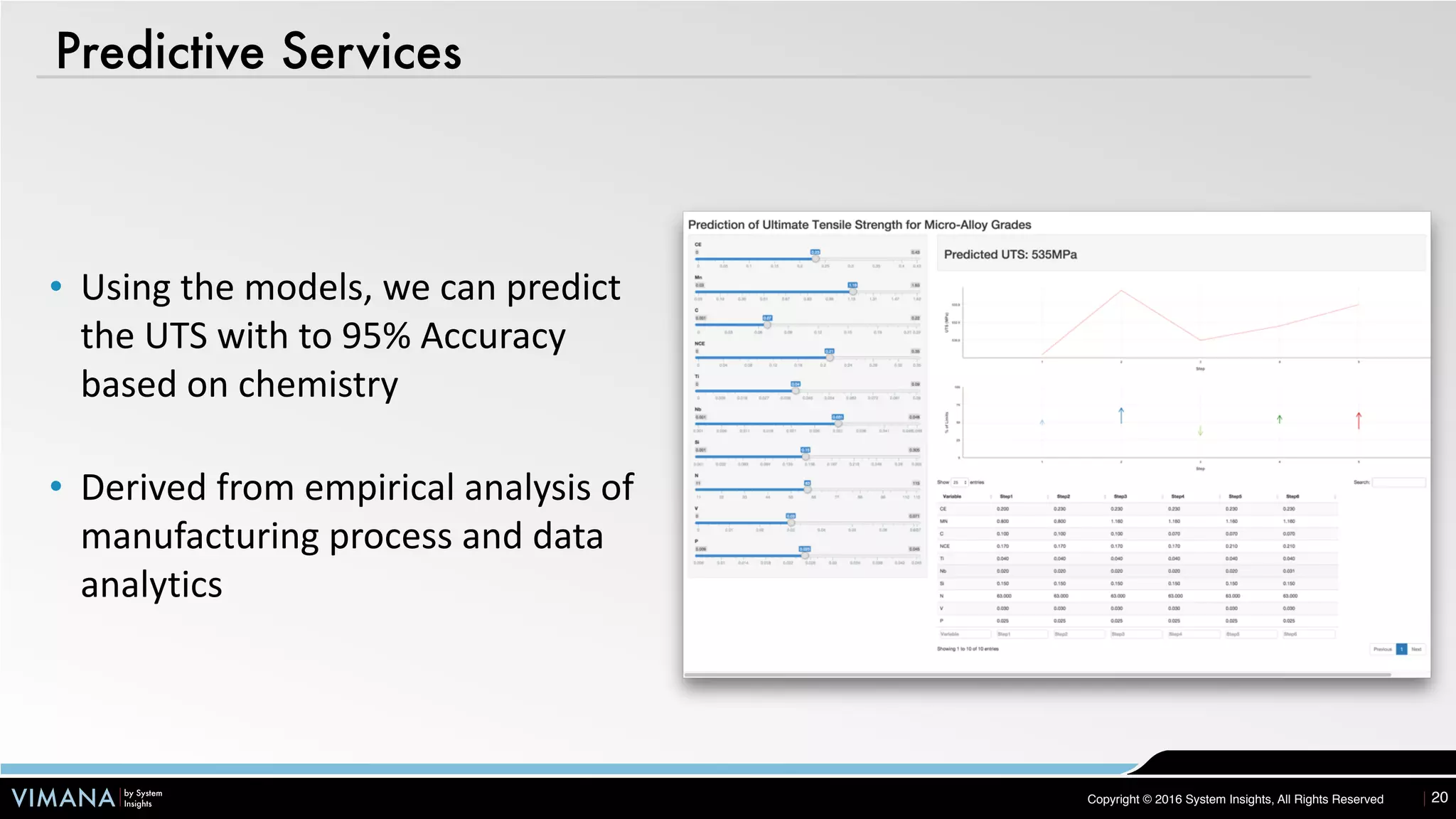

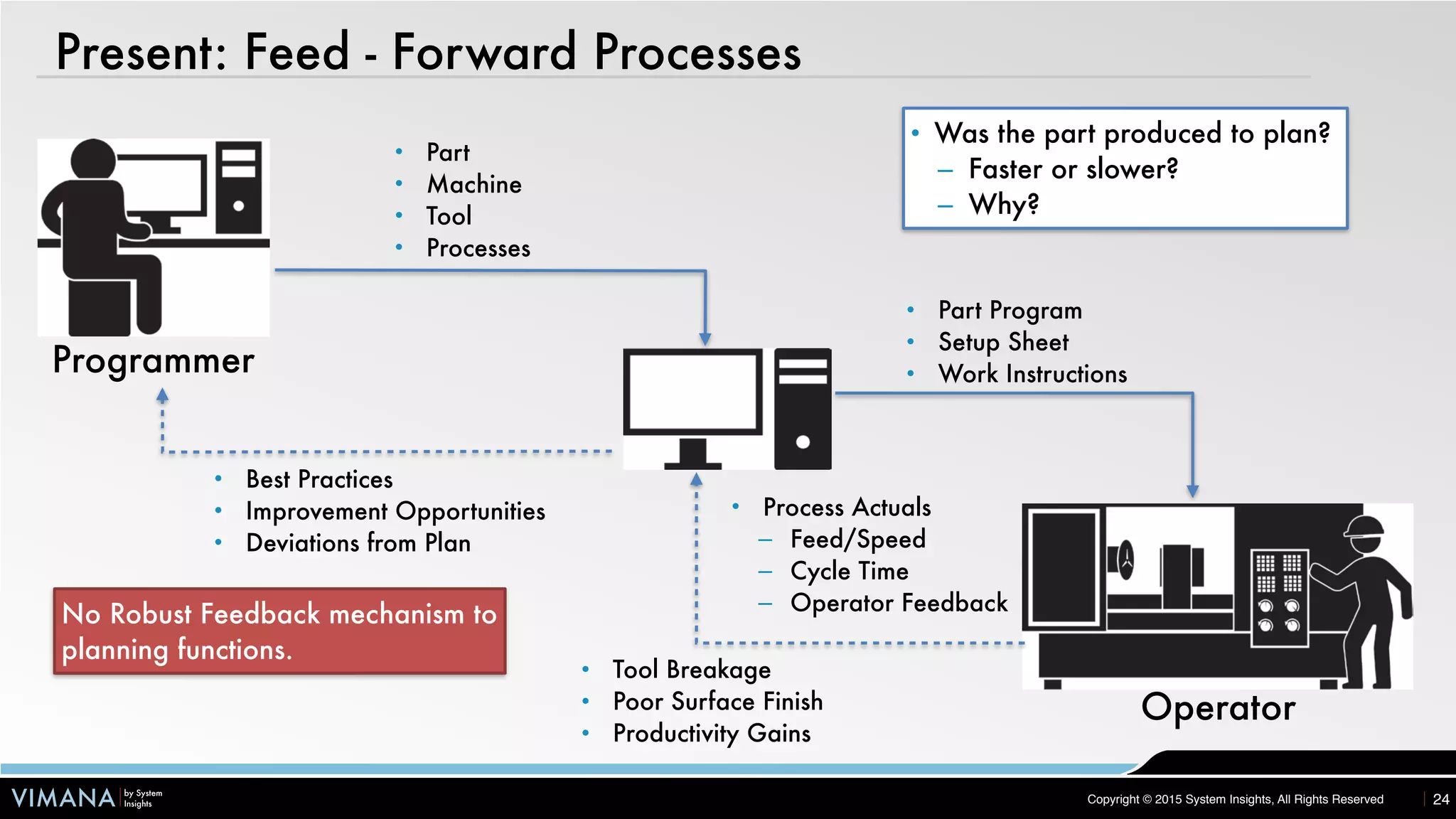

The IoT Inc Business Meetup in Silicon Valley focused on discussions around transforming data into valuable information for IoT products, highlighting the importance of analytics, modeling, and apps. Bruce Sinclair organized the meetup aiming to connect business professionals in the IoT sector, and future events are planned, including a mega meetup in July 2016. A presentation by William Sobel explored predictive analytics in manufacturing, emphasizing operational efficiencies and potential economic savings through enhanced data utilization.

![VIMANA by System

Insights Copyright © 2016 System Insights, All Rights Reserved

Semantic Transformation

31

0102030

40 50 60 70

8090100

010100100

a = 5000

b = 12.43

c = 87.22

d = 2

Device

Linear X

Position: 196.54mm

Load: 12.43%

Rotary C

Rotary Velocity: 87.22 RPM

Controller

Execution: ACTIVE

Meaning

Syntax SemanticsRaw Data

Propriatary Structure Wisdom

Bad

Good

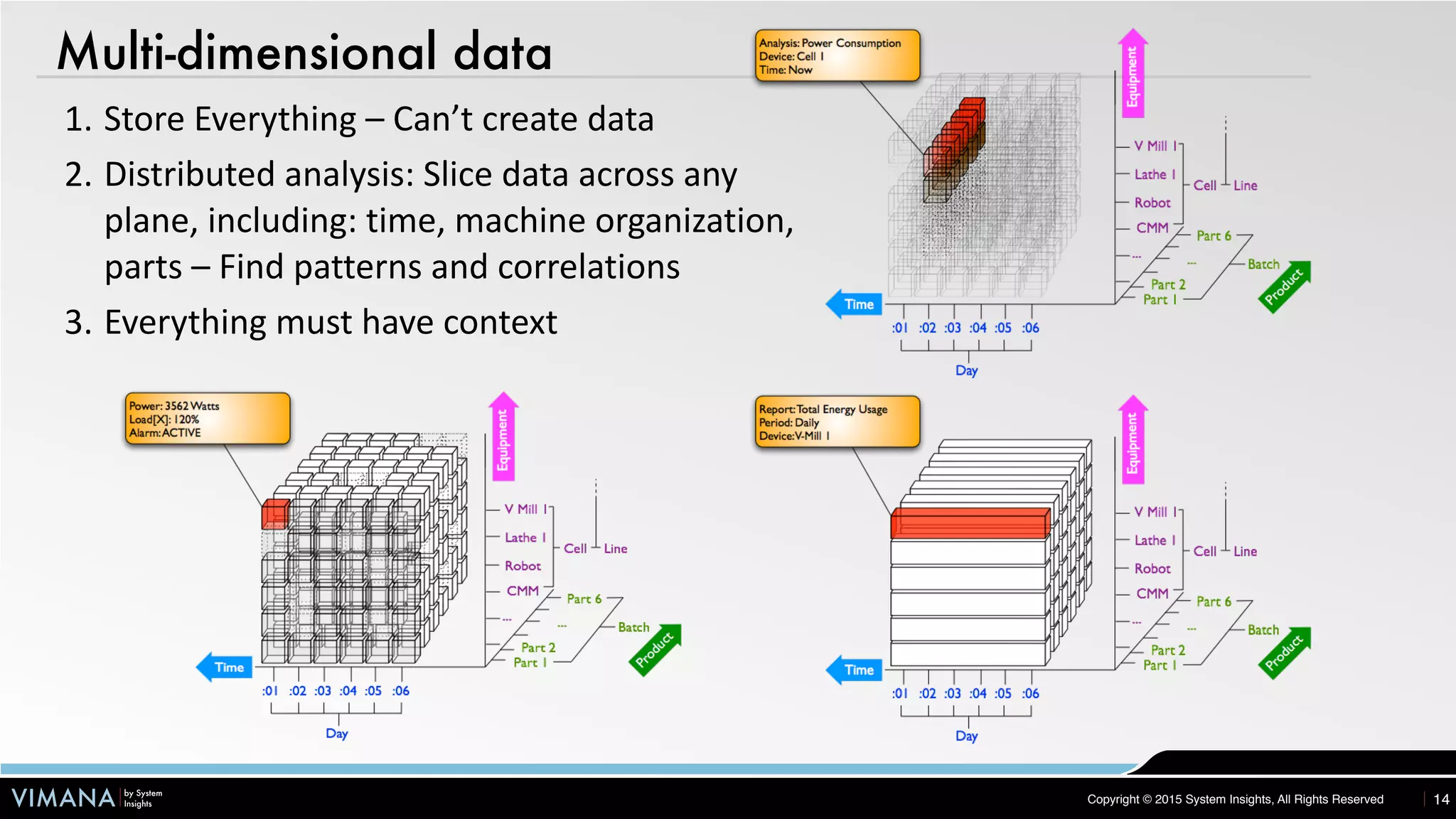

:01 :02 :03 :04 :05 :06

V Mill 1

Lathe 1

Robot

CMM

Cell

Day

Line

Part 1

Part 2

Part 6

......

Batch

Execution:ACTIVE

Load[X]: 120%

Feedrate[Override]: 80%

Time

Equipment

Product

Analysis Predictive

Prognositcs

Value

Information

Data Enrichment

part XY32 – part AB56 –

Producing part AB56

at avg. SS of 2500 RPM

Producing

unknown part

Producing part XY32

at avg. SS of 2160 RPM

–

Not Producing Producing

Producing State – Device: When All Paths Producing

Path 1

Path 2

MULTI-PATH Device

Not Producing Producing

Producing State – Device: When Any Paths Producing](https://image.slidesharecdn.com/iotbizmeetuppresentation18-160414182454/75/Predictive-Analytics-and-the-Industrial-Internet-of-Manufacturing-Things-with-Will-Sobel-37-2048.jpg)