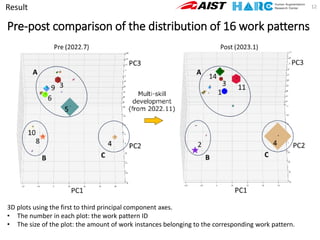

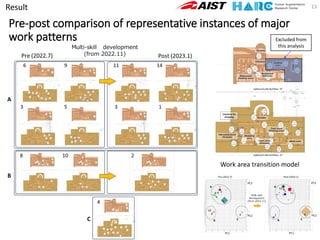

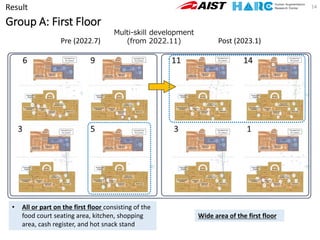

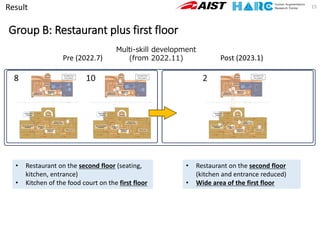

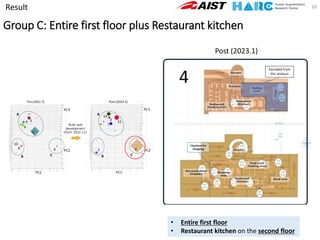

The document presents a case study analyzing work patterns and the effectiveness of multi-skill development using flow line data from employees at expressway service area facilities in Japan. It compares pre- and post-implementation metrics, revealing an increase in daily work areas and non-routine instances, although there was a slight decrease in the number of employees. The findings highlight the versatility of the work pattern analysis method traditionally used in automotive parts manufacturing in a service context, with suggestions for further comprehensive analysis methods and improvements.

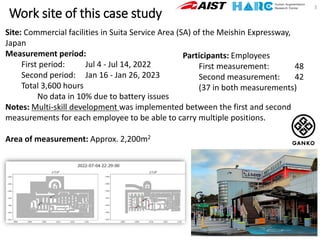

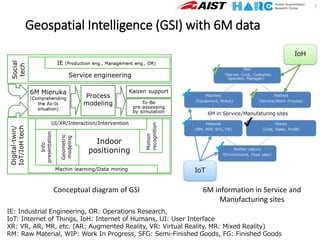

![Summary of pre-post multi-skill development

17

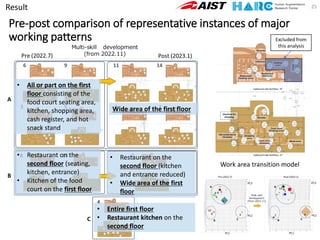

Pre Post Diff. Diff. [%] Stat. diff.

Avg. # of work areas/day (all) 11.1 13.3 2.2 19.8 Up, no test

(participation in both) 11.3 13.2 1.9 16.8 Up, p≒0.01

Walking distance [km/person-day] 4.6 5.0 0.5 10.2 Up, p≒0.036

# of non-routine instance 9.0 21.0 12.0 133.3 Up, no test

# of employees/day [median] 24.3 22.1 -2.2 -9.1 Down, p≒0.036

[SD] 2.8 1.5 -1.3 -46.3 Down, no test

Avg. hourly wage (July as 1) 1.00 1.03 0.03 3.00 Even, no test

Avg. sales/day (July as 1) 1.00 1.02 0.02 2.30 n.s., p≒0.747

Avg. length of work hours/person-day (July as 1) 1.00 1.07 0.07 6.60 Up, no test](https://image.slidesharecdn.com/apms2024-02040910-240911155306-31a48fca/85/Pre-Post-Analysis-on-Multi-Skill-Development-using-Flow-Line-Data-at-Expressway-Service-Area-Facilities-17-320.jpg)

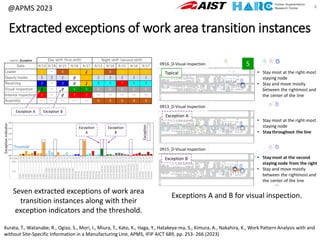

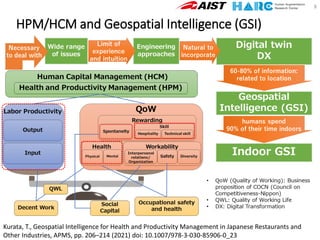

![Comparison of two case studies

18

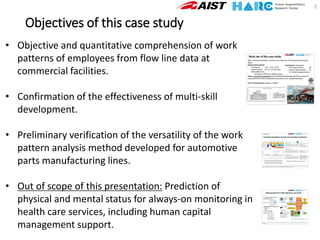

Auto parts mfg. line Expressway SA Facilities

# of all stay nodes 21 29

# of stay nodes for analysis 13 28

# of stay length levels 4 9

Model dimensions 525 1,102

46 415

12 16

7 30

15.2 7.2

Meas. area [m

2

] 1,400 2,200

# of BLE beacons 56 97

Days of meas. 5 20

# of subjects 10 53

Etc.

# of roles 6 24

# of work areas for analysis 10 25

Etc.

Floor plans, BLE beacon layout

site-specific

detailed

information

Work area classification, Shift , Attendance records,

Outputs (# of productions, sales)

Work

area

transition

model

# of work instarnces

# of work patterns

# of non-routine instances

non-routine ratio [%]

Information

for

measurement/

prepapration

non-routine ratio: the ratio of the number of non-routine work instances to the total number of work instances

• manufacturing site to service site

• Larger site

APMS 2023 APMS 2024](https://image.slidesharecdn.com/apms2024-02040910-240911155306-31a48fca/85/Pre-Post-Analysis-on-Multi-Skill-Development-using-Flow-Line-Data-at-Expressway-Service-Area-Facilities-18-320.jpg)