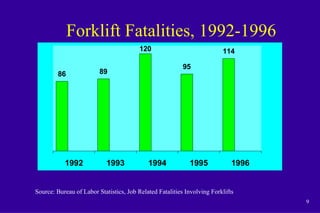

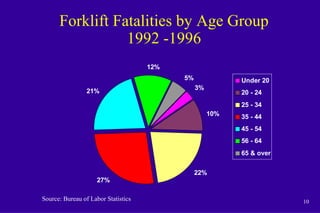

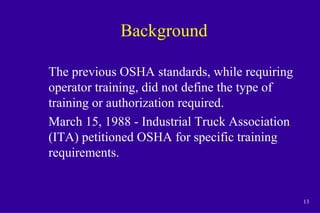

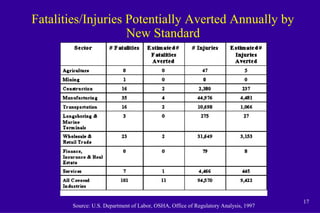

This document provides an overview of OSHA's powered industrial truck operator training requirements. It defines powered industrial trucks and outlines the scope of OSHA's standard. It describes the reasons for developing new, more specific training requirements including the number of injuries and fatalities caused by powered industrial trucks annually. The document summarizes the key elements of the new training standard including required training topics, refresher training, certification of operators, and an effective training program. It also provides examples of common types of powered industrial trucks.

![4

Powered Industrial

Truck - Definition

A mobile, power-propelled truck used to carry, push,

pull, lift, stack or tier materials. [American Society of

Mechanical Engineers (ASME) definition]

Excluded are vehicles used for earth moving and over-

the-road hauling.

Commonly known as forklifts, pallet trucks, rider

trucks, forktrucks, or lifttrucks.

Can be powered through electric or combustion

engines.](https://image.slidesharecdn.com/poweredindustrialtrucksoshastd-130722100405-phpapp01/85/Powered-industrial-trucks-osha-std-4-320.jpg)