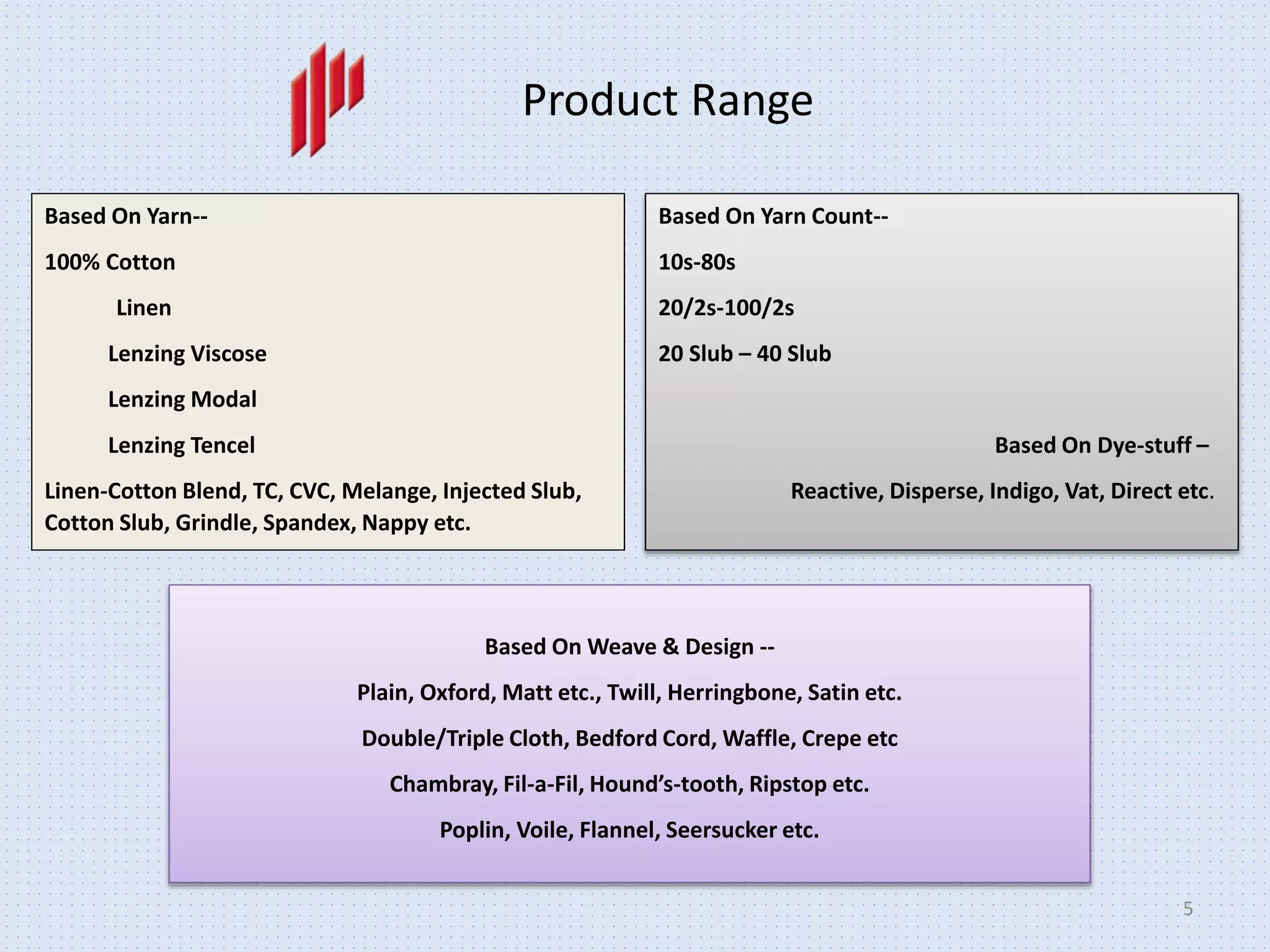

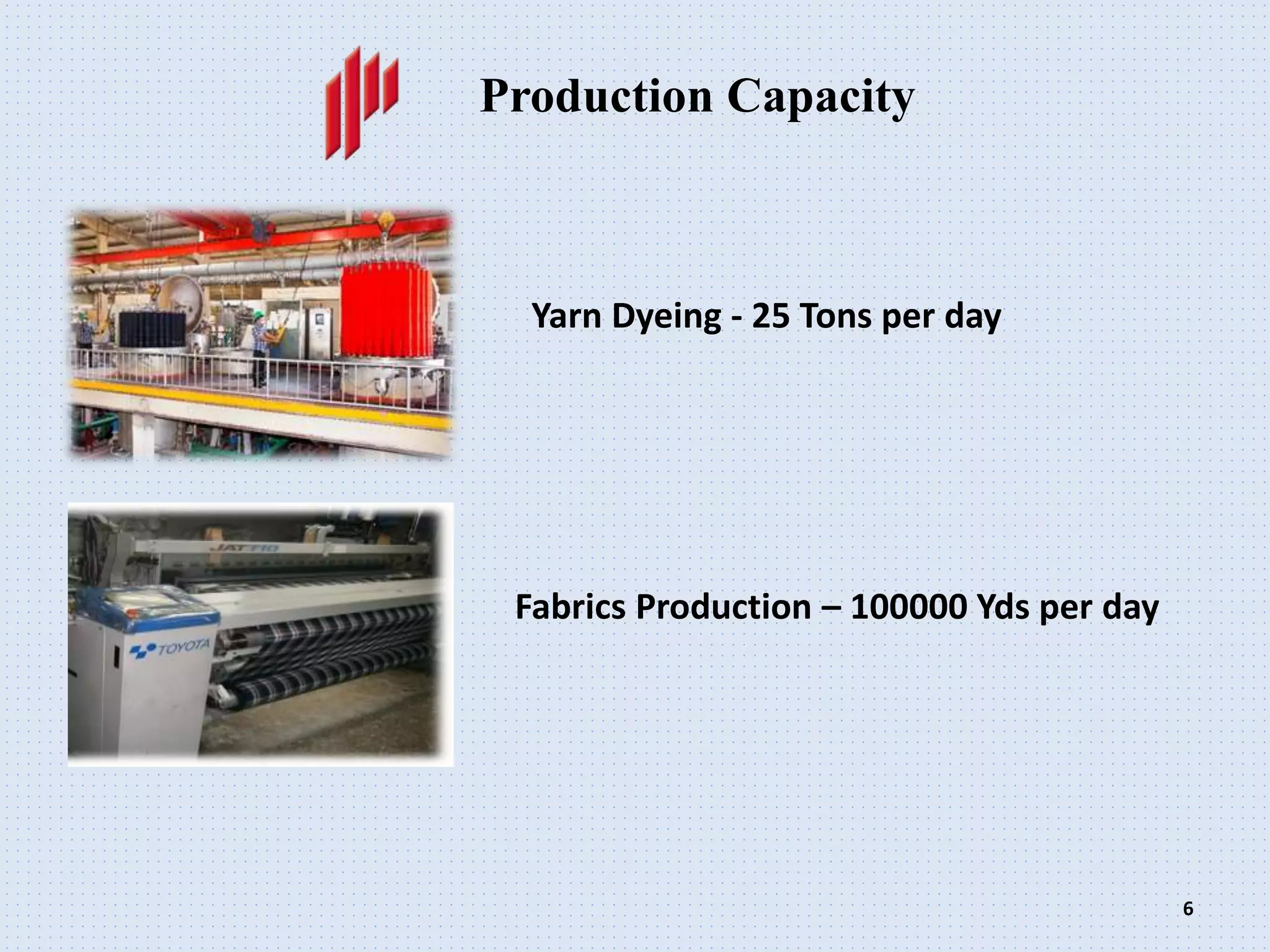

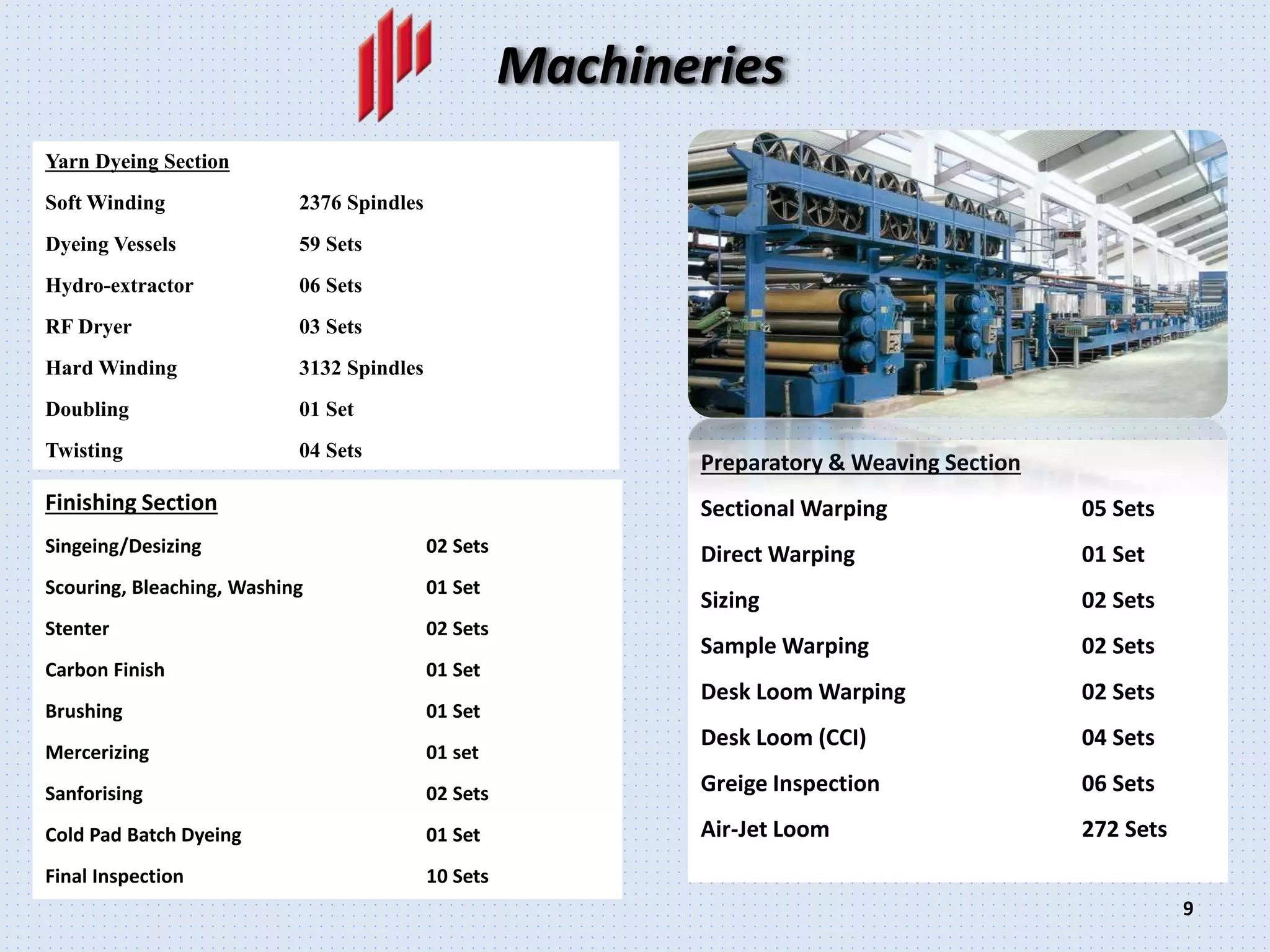

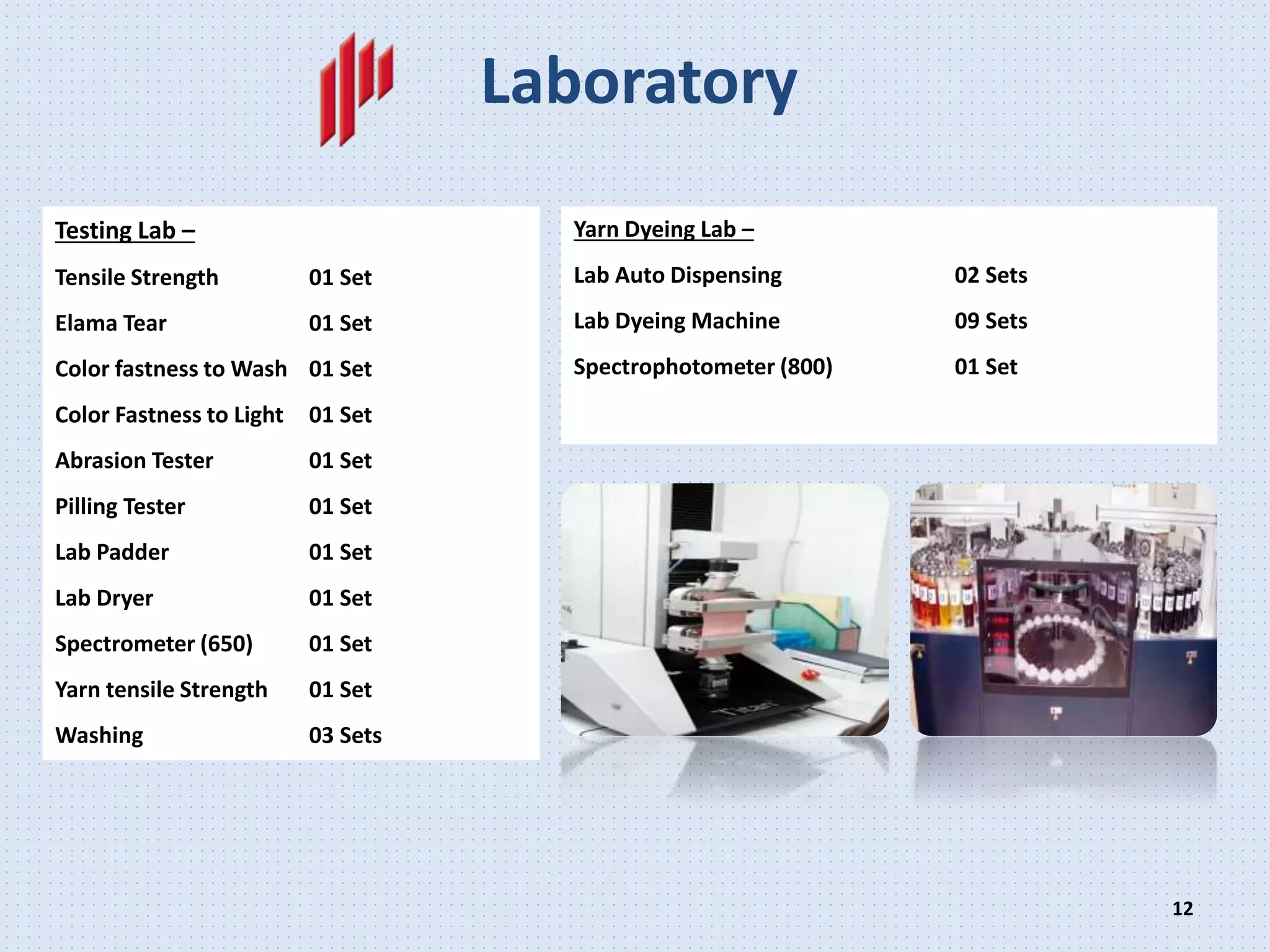

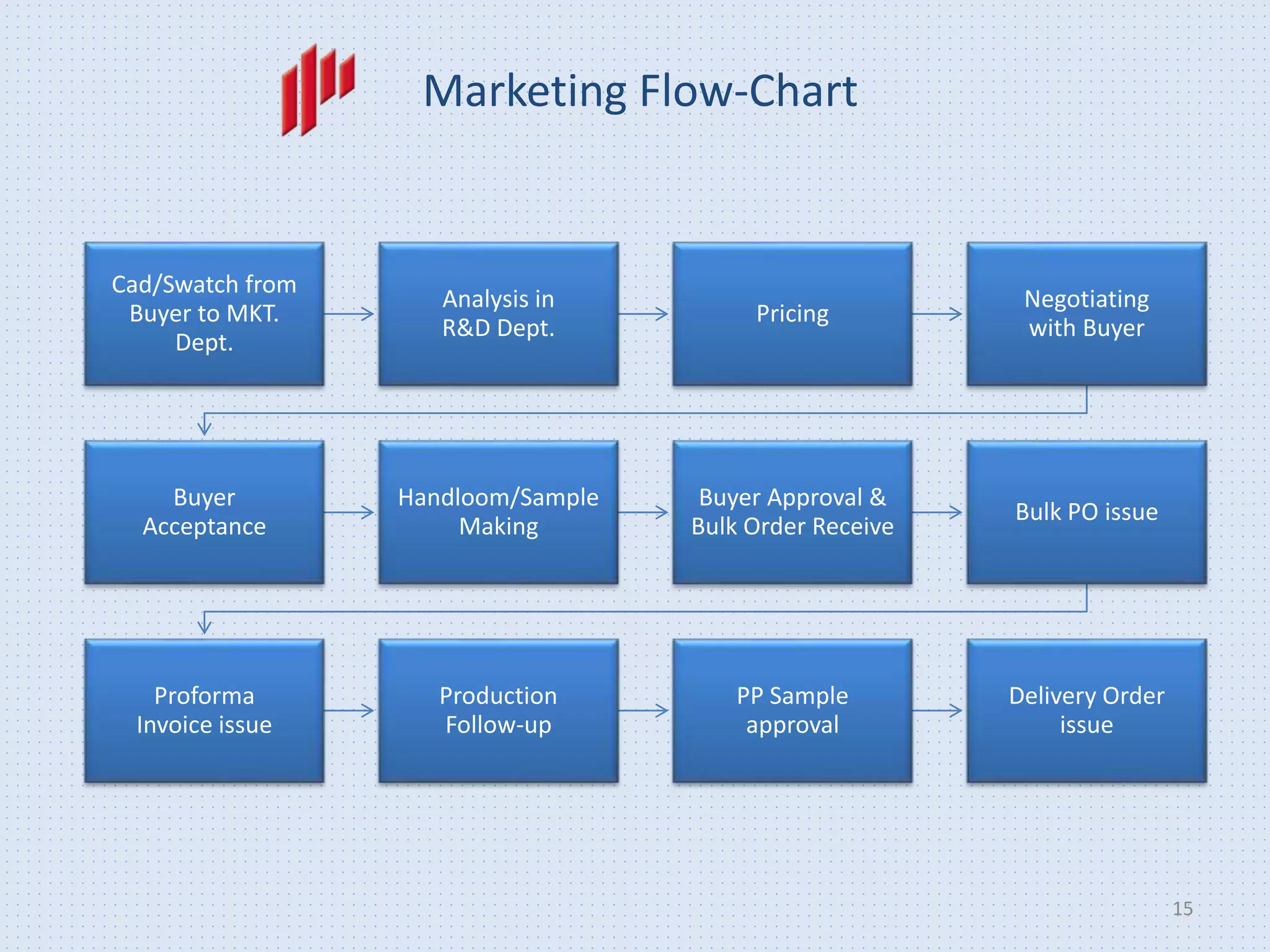

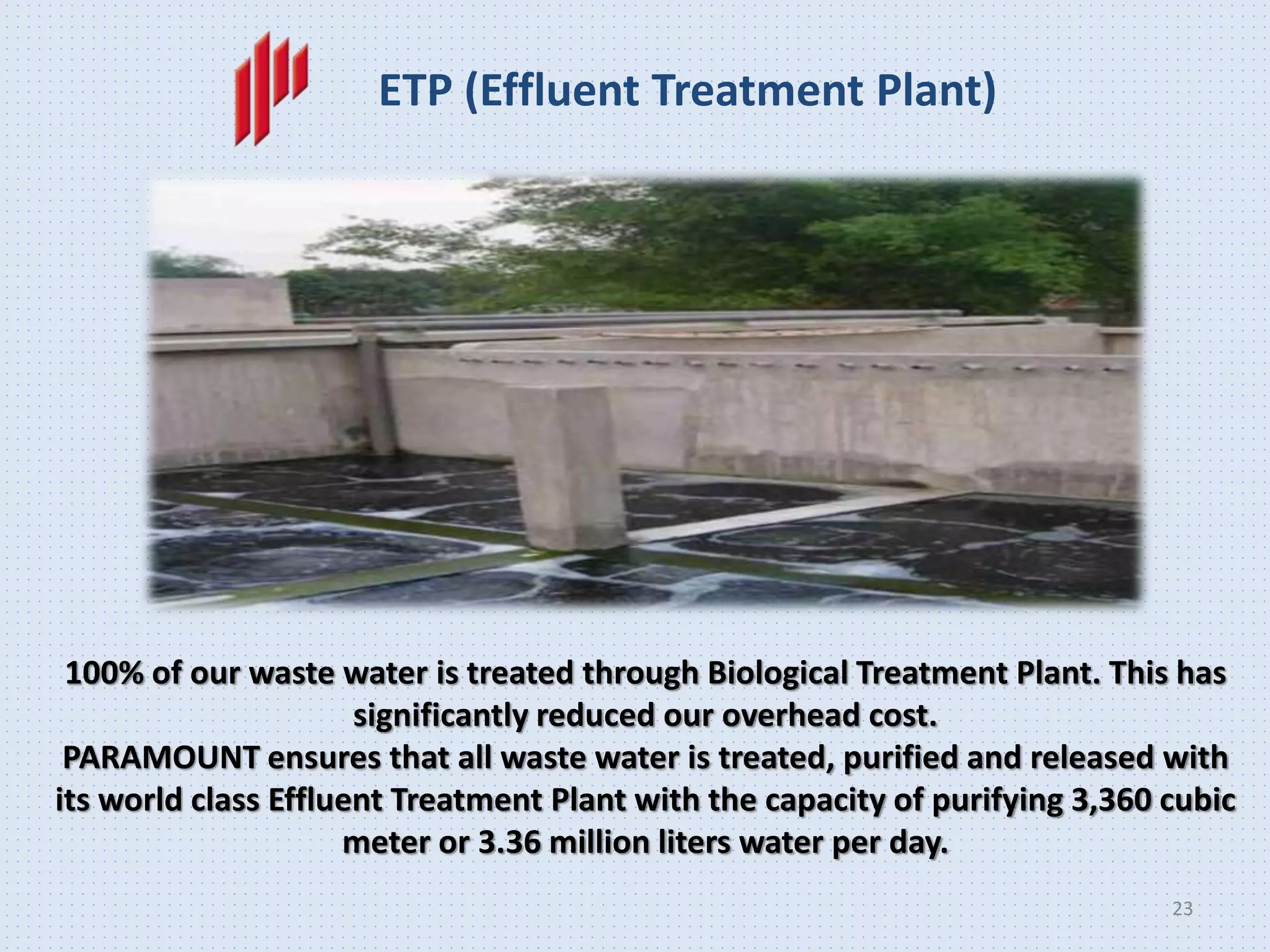

Paramount Textile Limited is a leading manufacturer of yarn dyed woven fabrics in Bangladesh, established in 2006 and listed on the stock exchange in 2010. The company is Oeko-Tex certified and produces a wide variety of high-quality fabrics for global fashion brands, utilizing advanced technology and a substantial production capacity. With strong commitments to quality, sustainability, and innovation, Paramount has established a significant presence in the international textile market.