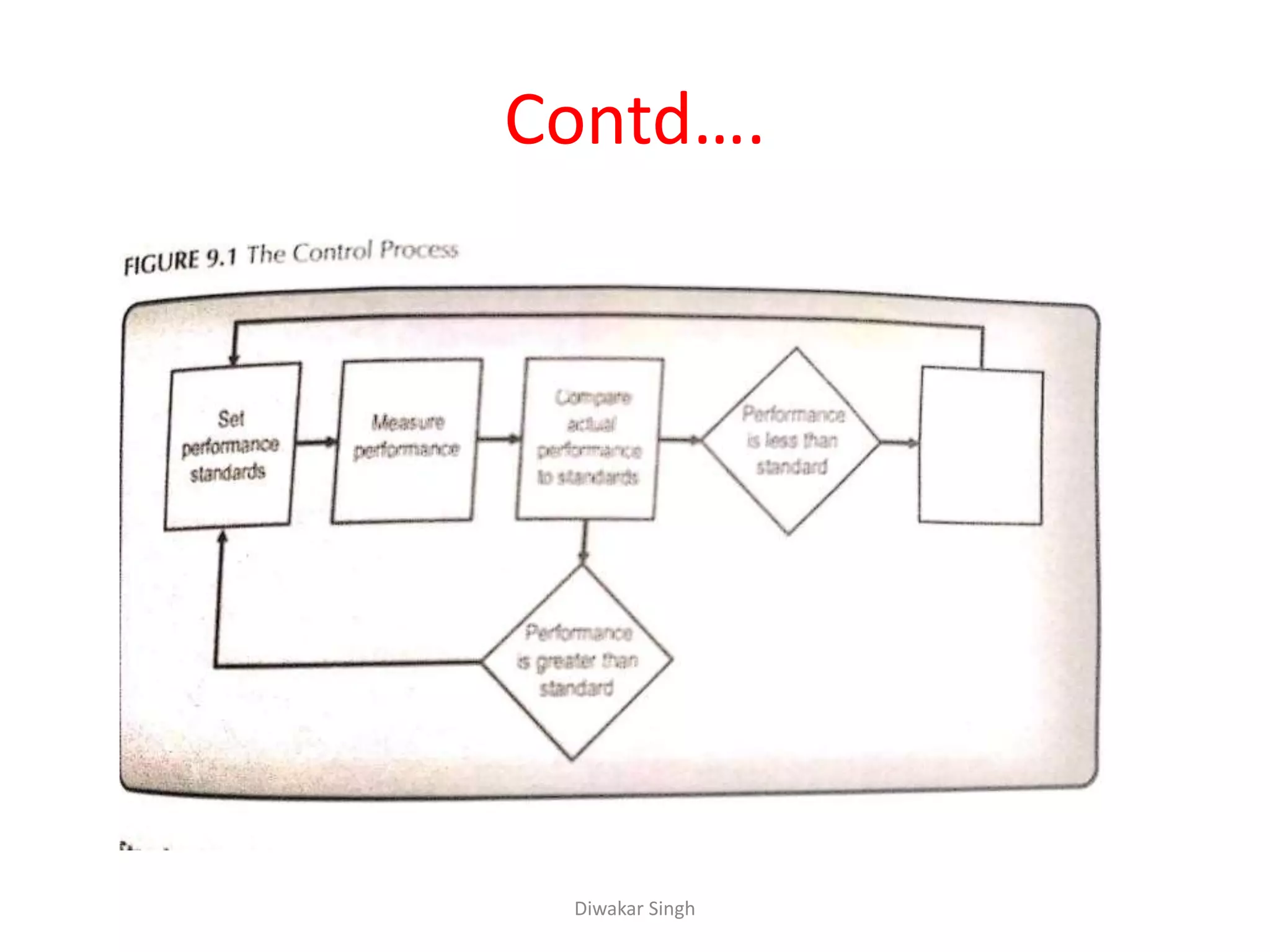

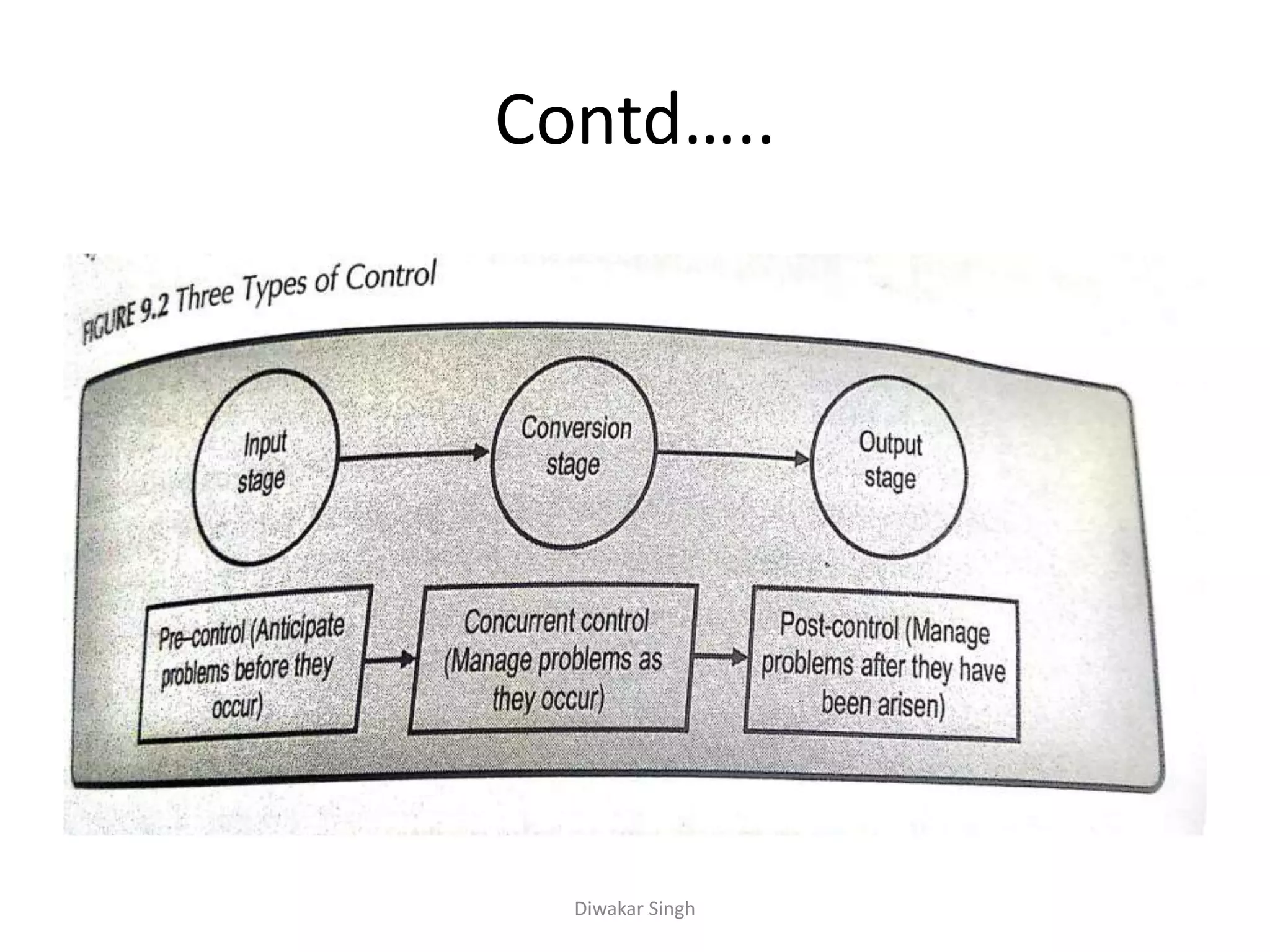

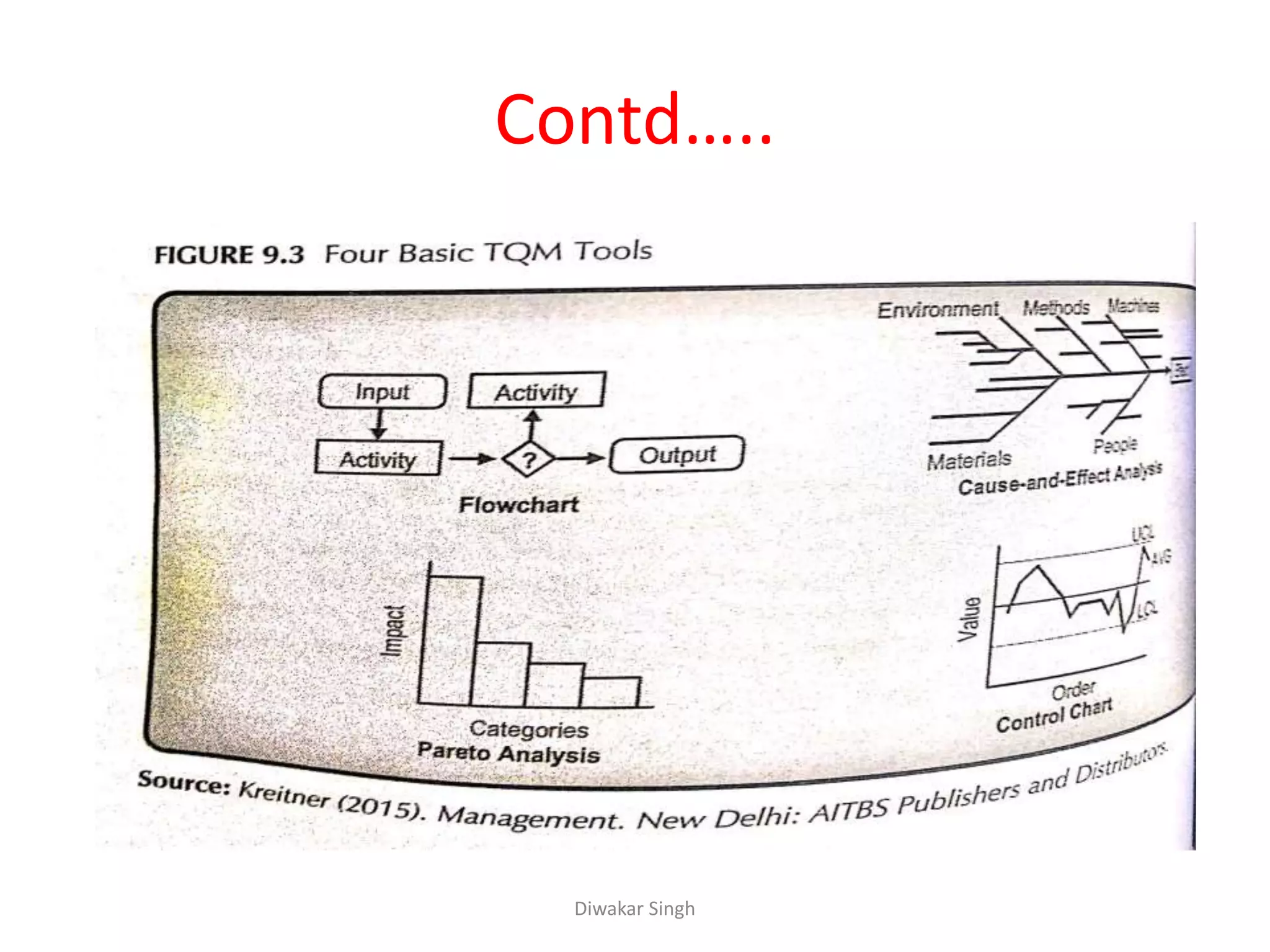

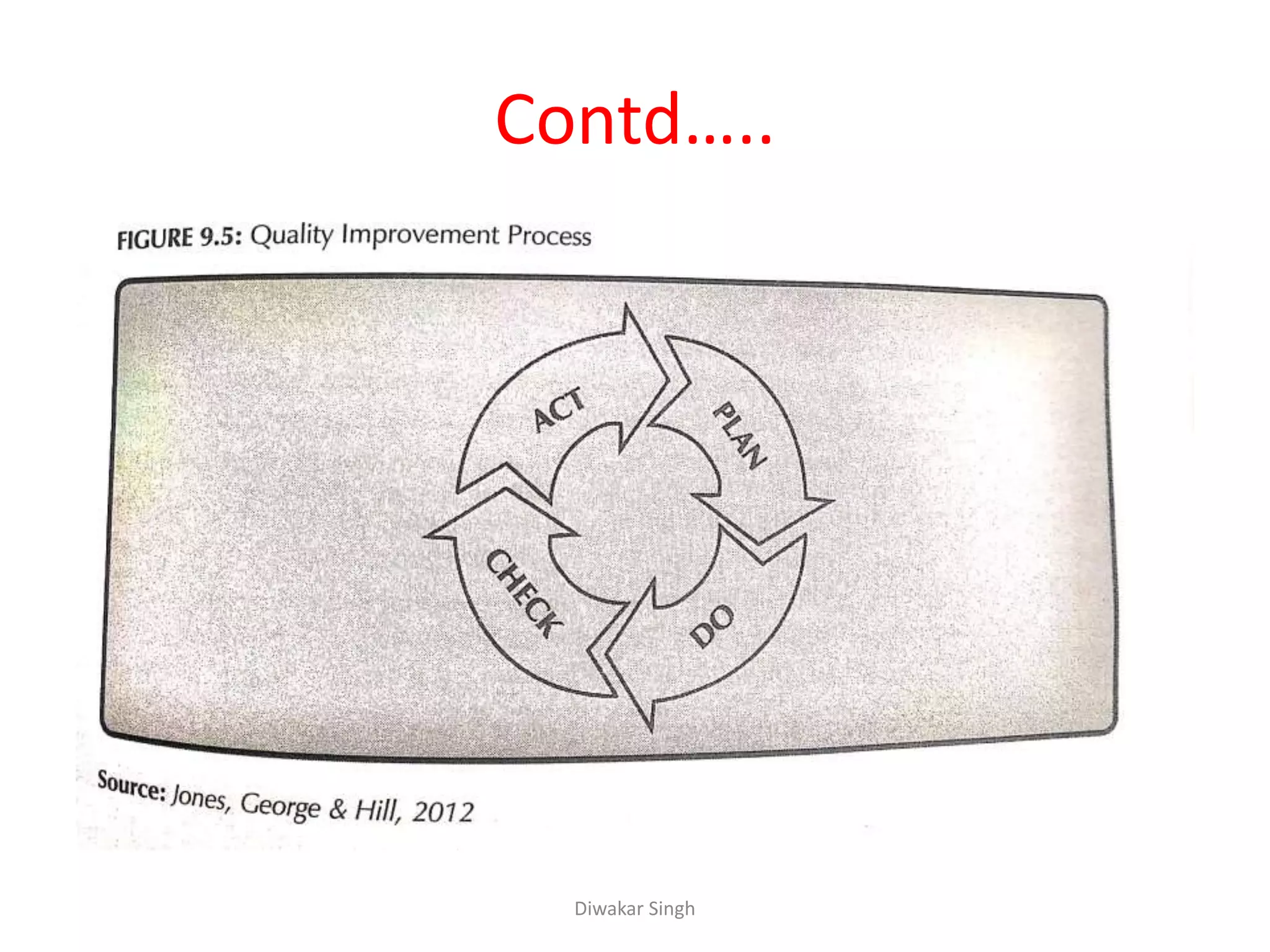

This document provides an overview of control and quality management. It discusses the basic concepts of control systems, including the control process of setting performance standards, measuring performance, comparing to standards, and taking corrective action. It describes different types of control systems like pre-control, concurrent control, and post-control. The document also outlines characteristics of effective control systems and potential barriers to successful controlling, such as resource scarcity and inaccurate measurement. Finally, it briefly discusses quality control systems and determining standards to measure quality.