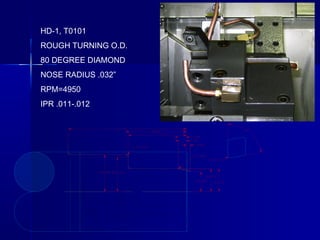

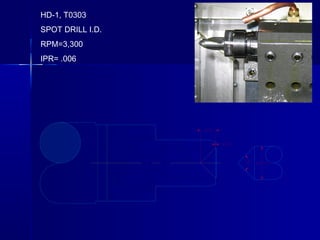

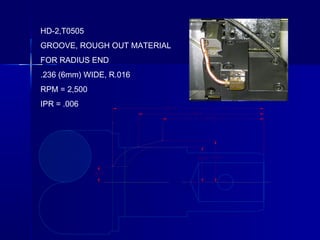

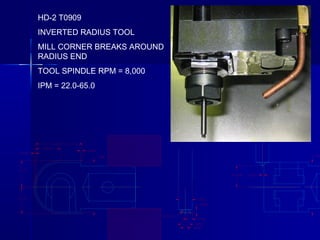

The document discusses the 2013 technical conference for PMPA and provides details on CNC multi-function printing for machining an aluminum part including tolerances, materials, machining processes, tooling, and cycle times. Key steps include rough and finish turning, drilling, milling flats and slots, cutting radii and corners, and deburring. The part will be machined from 2011-T3 aluminum alloy using multiple spindles and tools with a target cycle time of 3 minutes 24 seconds and a production rate of around 17 pieces per hour.

![CNC MULTI-FUNCTION

- Block Tolerances - - Notes - - Job Information -

Unless Otherwise Specified TITLE:

2013 TECHNICAL CONFERENCE

LINEAR DIMENSIONS BLACK ANODIZE LINK

.XXX ± .005 COATING ANNUAL QUANTITY: 12,000

.XX ± .010

LOT SIZE : 6,000

ANGULAR ± 1/2° or 30'

MATERIAL :

BREAK ALL CORNERS 2011-T3 ALUMINUM

.0078 [MAX.] x 45°

Customer Requirements:

SURFACE FINISH BREAK ALL CORNERS

63 Ra ALL SURFACES](https://image.slidesharecdn.com/pmpatechnicalconfrence-130313125836-phpapp01/85/Pmpa-technical-confrence-2-320.jpg)

![HD-1, T0909

MILL FLATS [4 PLCS.]

@ 90 Degree

Tool Spindle RPM = 4,000

Roughing IPM = 95.0

Finishing IPM = 30.0](https://image.slidesharecdn.com/pmpatechnicalconfrence-130313125836-phpapp01/85/Pmpa-technical-confrence-10-320.jpg)

![HD-1, T0808

Cross Drill [2 PLCS.]

#21 Drill (Ø.1590)

Tool Spindle RPM = 4,000

IPM = 17.0](https://image.slidesharecdn.com/pmpatechnicalconfrence-130313125836-phpapp01/85/Pmpa-technical-confrence-11-320.jpg)

![HD-1, T0707

MILL SLOTS [2 PLCS.]

TOOL SPINDLE RPM = 8,000

ROUGHING IPM = 100.0

FINISHING IPM = 12.0](https://image.slidesharecdn.com/pmpatechnicalconfrence-130313125836-phpapp01/85/Pmpa-technical-confrence-18-320.jpg)

![HD-3, T0707

DE-BURR MILL SLOTS [2 PLCS.]

TOOL SPINDLE RPM = 8,000

FINISHING IPM = 15.0](https://image.slidesharecdn.com/pmpatechnicalconfrence-130313125836-phpapp01/85/Pmpa-technical-confrence-21-320.jpg)