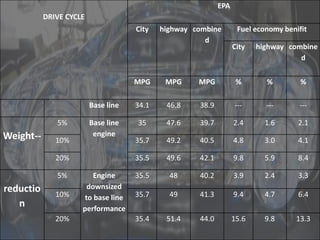

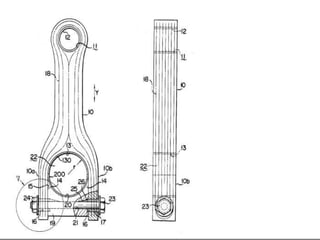

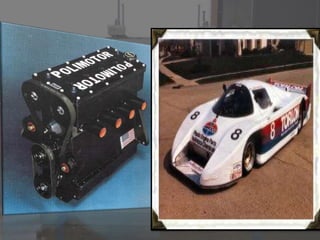

The document discusses the proliferation of plastics in internal combustion engines. It began when Henry Ford first used plastics for components like horn buttons and gears in his cars. Later, Matty Holtzberg experimented with plastic pistons and connecting rods and founded Polimotor to develop plastic-intensive engines using materials like Torlon, which can withstand high temperatures. The purpose is to reduce weight and improve fuel efficiency, with potential savings of 1-2% per 100 pounds reduced. However, some plastics emit gases that can irritate drivers.

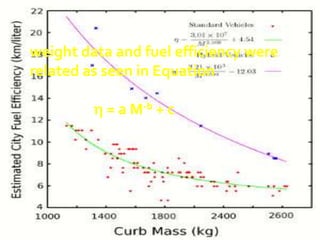

![• For standard vehicles, efficiency equation is,

η = [ (3.01×107 ) / M2.140 ] + 4.54.

• For Hybrid vehicles, efficiency equation is,

η = [(2.21×103) /M0.545 ] – 12.03.](https://image.slidesharecdn.com/plasticproliferationoficengine-150119015310-conversion-gate02/85/Plastic-proliferation-of-IC6-engine-7-320.jpg)