PhD After completing the learning tasks, the learners will be able toConfirmation.pptx

•Download as PPTX, PDF•

0 likes•1 view

After completing the learning tasks, the learners will be able to

Report

Share

Report

Share

Recommended

Recommended

Influence of Novel machining on the mechanical and damage characterization of self reinforced polymer compositesInfluence of Novel machining on the mechanical and damage characterization of...

Influence of Novel machining on the mechanical and damage characterization of...Padmanabhan Krishnan

More Related Content

Similar to PhD After completing the learning tasks, the learners will be able toConfirmation.pptx

Influence of Novel machining on the mechanical and damage characterization of self reinforced polymer compositesInfluence of Novel machining on the mechanical and damage characterization of...

Influence of Novel machining on the mechanical and damage characterization of...Padmanabhan Krishnan

Similar to PhD After completing the learning tasks, the learners will be able toConfirmation.pptx (20)

APPLICATION OF GREY RELATIONAL ANALYSIS FOR MULTI VARIABLE OPTIMIZATION OF PR...

APPLICATION OF GREY RELATIONAL ANALYSIS FOR MULTI VARIABLE OPTIMIZATION OF PR...

IRJET- Study of Fused Deposition Modeling Process Parameters for Polycarbonat...

IRJET- Study of Fused Deposition Modeling Process Parameters for Polycarbonat...

Effect of short glass fiber and fillers on dry sliding wear behaviour of ther...

Effect of short glass fiber and fillers on dry sliding wear behaviour of ther...

Influence of Novel machining on the mechanical and damage characterization of...

Influence of Novel machining on the mechanical and damage characterization of...

EFFECT OF SHORT GLASS FIBER AND FILLERS ON DRY SLIDING WEAR BEHAVIOUR OF THER...

EFFECT OF SHORT GLASS FIBER AND FILLERS ON DRY SLIDING WEAR BEHAVIOUR OF THER...

A Review on Finite Element Analysis of Automobile roof header Manufactured By...

A Review on Finite Element Analysis of Automobile roof header Manufactured By...

Optimization of machining parameters in edm of cfrp composite using taguchi t...

Optimization of machining parameters in edm of cfrp composite using taguchi t...

Investigation into the effects of process parameters on delamination 2

Investigation into the effects of process parameters on delamination 2

IRJET- Optimization of Laser Transmission Welding Process Parameters using Si...

IRJET- Optimization of Laser Transmission Welding Process Parameters using Si...

OPTIMIZATION OF MACHINING PARAMETERS IN EDM OF CFRP COMPOSITE USING TAGUCHI T...

OPTIMIZATION OF MACHINING PARAMETERS IN EDM OF CFRP COMPOSITE USING TAGUCHI T...

Optimization of machining parameters in edm of cfrp composite using taguchi t...

Optimization of machining parameters in edm of cfrp composite using taguchi t...

CHARACTERIZATION AND ANALYSIS OF MECHANICAL PROPERTIES FOR 3D PRINTING MATERIALS

CHARACTERIZATION AND ANALYSIS OF MECHANICAL PROPERTIES FOR 3D PRINTING MATERIALS

Parametric analysis of GFRP composites in CNC milling machine using Taguchi m...

Parametric analysis of GFRP composites in CNC milling machine using Taguchi m...

Research problem statementThe main problem is to achieve mecha.docx

Research problem statementThe main problem is to achieve mecha.docx

ANALYSIS OF SHRINKAGE AND WARPAGE DISPLACEMENT USING CONFORMAL COOLING

ANALYSIS OF SHRINKAGE AND WARPAGE DISPLACEMENT USING CONFORMAL COOLING

Recently uploaded

Recently uploaded (20)

Standard vs Custom Battery Packs - Decoding the Power Play

Standard vs Custom Battery Packs - Decoding the Power Play

HOA1&2 - Module 3 - PREHISTORCI ARCHITECTURE OF KERALA.pptx

HOA1&2 - Module 3 - PREHISTORCI ARCHITECTURE OF KERALA.pptx

Linux Systems Programming: Inter Process Communication (IPC) using Pipes

Linux Systems Programming: Inter Process Communication (IPC) using Pipes

DC MACHINE-Motoring and generation, Armature circuit equation

DC MACHINE-Motoring and generation, Armature circuit equation

💚Trustworthy Call Girls Pune Call Girls Service Just Call 🍑👄6378878445 🍑👄 Top...

💚Trustworthy Call Girls Pune Call Girls Service Just Call 🍑👄6378878445 🍑👄 Top...

PE 459 LECTURE 2- natural gas basic concepts and properties

PE 459 LECTURE 2- natural gas basic concepts and properties

Basic Electronics for diploma students as per technical education Kerala Syll...

Basic Electronics for diploma students as per technical education Kerala Syll...

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

Digital Communication Essentials: DPCM, DM, and ADM .pptx

Digital Communication Essentials: DPCM, DM, and ADM .pptx

Orlando’s Arnold Palmer Hospital Layout Strategy-1.pptx

Orlando’s Arnold Palmer Hospital Layout Strategy-1.pptx

Theory of Time 2024 (Universal Theory for Everything)

Theory of Time 2024 (Universal Theory for Everything)

PhD After completing the learning tasks, the learners will be able toConfirmation.pptx

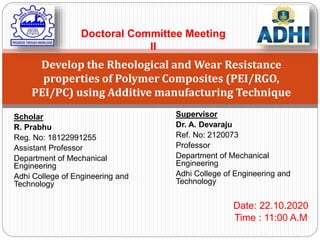

- 1. Scholar R. Prabhu Reg. No: 18122991255 Assistant Professor Department of Mechanical Engineering Adhi College of Engineering and Technology Develop the Rheological and Wear Resistance properties of Polymer Composites (PEI/RGO, PEI/PC) using Additive manufacturing Technique Supervisor Dr. A. Devaraju Ref. No: 2120073 Professor Department of Mechanical Engineering Adhi College of Engineering and Technology Date: 22.10.2020 Time : 11:00 A.M Doctoral Committee Meeting II

- 2. DC Member 1 : Dr. N. Venkateswaran Professor Department of Mechanical Engineering Rajalakshmi Engineering College Thandalam DC Member 2 : Dr. M. Seeman Associate Professor Department of Manufacturing Engineering Annamalai University Chidambaram

- 3. Course Work Done S.No Course Code Course Title Credit s Letter Grade Grade Point GPA 1 ED507 4 Tribology in Design 3 A+ 9 8.00 2 ED500 4 Surface Engineering 3 B+ 7 3 CC529 2 Additive Manufacturing and Tooling 3 A 8 7.00 4 ED507 8 Composite Materials and Mechanics 3 B 6 Cummulative Grade Point Average (CGPA) : 7.50

- 4. Grade Sheets for Course Work Examinations

- 5. Comprehensive Evaluation for Confirmation of Registration Comprehensive Evaluation was conducted on 16 Oct 2020 by Supervisor. Topics Covered : Polymers, Polymer Composites, Additive Manufacturing, and Tribology Total Marks : 100 Timing : 100 Minutes Total Mark Secured : 84

- 6. Comprehensive Evaluation for Confirmation of Registration

- 7. Research Paper Published Failure analysis and restructuring model of transfer feeder gear box in thermal powerplant R Prabhu, A Devaraju Materials Today: Proceedings 2020 (Scopus Indexed) Recent review of tribology, rheology of biodegradable and FDM compatible polymers R Prabhu, A Devaraju Materials Today: Proceedings 2020 (Scopus Indexed)

- 8. Objectives To develop the Polymer composites (PEI/RGO and PEI/PC) using Additive Manufacturing Technique. To Measure the Rheological, Thermal Stability of the fabricated composites. To Evaluate the wear rate and coefficient of friction using Tribological along with Surface Topography studies.

- 9. PEI (ULTEM1000) Amorphous Polymer High Glass Transition Temperature (217°C) High Strength and Thermal Stability Resistance to Chemicals Compatible for Additive Manufacturing Process

- 10. Blending Material Reduced Graphene Oxide (RGO) Promising Material Oxidized Functional Groups were removed Leads to increased interlayer spacing and functionalization. Hydrophilic Polycarbonate (PC) Appropriate Material Resistance to impact and flame Versatile

- 11. Fused Deposition Modeling (FDM) Process Cheap and Simpler Fabricate – without wastage Control and Vary – Parameters Multiple Output

- 12. Parameters in FDM Layer thickness Deposition flow rate Raster angle Air gap Part orientation Filling velocity Road width

- 13. Slice thickness Deposition style Wire width compensation Extrusion velocity Scan speed Model temperature

- 14. Rheological Study To study of the flow Characters of the polymers. It impose a specific stress field or deformation to the fluid, and monitor the resultant deformation or stress. Used to describes the interrelation between force, deformation and time. It measures the torque and the deflection angle.

- 15. Atomic Force Microscope (AFM) Shows the Dispersion of GO and PC Evaluating force interactions between molecules Studying the physical changing properties of Molecules 3D imaging

- 16. Thermo Gravimetric Analysis (TGA) To Evaluate the thermal stability To Measure the fraction of volatile components by monitoring the weight change that occurs as a sample is heated at a constant rate. Temperature Vs Weight %

- 17. Dynamic Mechanical Analysis (DMA) To study the viscoelastic behavior Used to characterize a material's properties as a function of temperature, time, frequency, stress, atmosphere or a combination of these parameters.

- 18. Tribology (Pin on Disc) To Evaluate the Wear rate To Measure the co-efficient of Friction Analyzing the material deformation

- 19. Trinocular Optical Microscope and SEM Used to Study the surface topography on the surfaces of polymer composites. Physical Features after sliding contact.

- 20. Applications Polymer bearings in submersible Turbines Low Wear rates Anti Corrosion Property Self Lubricants Versatile and Economical Freedom from maintenance No messy Lubricants Consistent Coefficient of Friction

- 21. Polymer Bearing

- 22. Methodolog y Polyetherimide, RGO, PC Blending of Polyetherimide with RGO and PC (Extruder) Fabrication of Materials through FDM Considering Various Parameters Rheological and Characterization Study Wear and Friction measurements through Tribology Surface topography studies Result and Conclusion

- 23. Work Plan Research Work Jan 18 Jul 19 Jan 20 Oct 20 Nov 20 Jul 21 Dec-21 Jun-22 Literature Review Course Work Review Paper Submission and Confirmation Fabrication and Experimental evaluation of proposed work Result and Discussion, Research paper Presentation Expected year of Synopsis submission

- 24. Literatures Chengcheng Liu, Yanbao Guoa, Deguo Wang, PEI- RGO nanosheets as a nanoadditive for enhancing the tribological properties of water-based lubricants, Tribol. Int. 140 (2019) Blanco I, Cicala G, Ognibene G, Rapisarda M, Recca A, Thermal properties of polyetherimide /polycarbonate blends for advanced applications, Polymer Degradation and Stability (2018), doi: 10.1016/j.polymdegradstab.2018.06.011.

- 25. R. Anitha, S. Arunachalam, P. Radhakrishnan, Critical parameters influencing the quality of prototypes in fused deposition modelling, J. Mater. Process. 781 Technol. 118 (2001) 385–388. Marissa Giovino, Julia Pribyl, Brian Benicewicz, Sanat Kumar, Linda Schadler, Linear Rheology of polymer nanocomposites with polymer-grafted nanoparticles, Polymer 131 (2017) 104–110.

- 26. Thank You