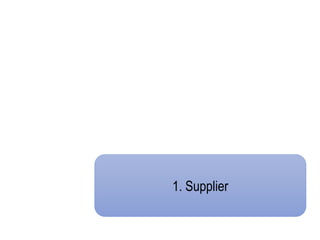

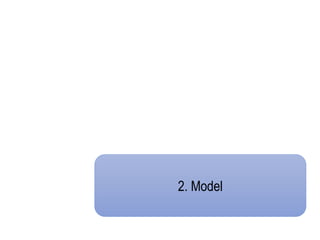

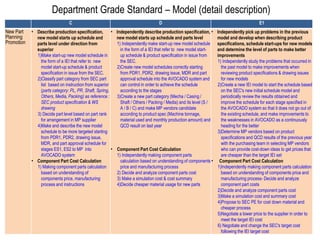

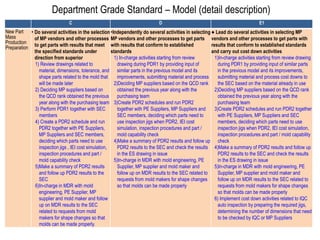

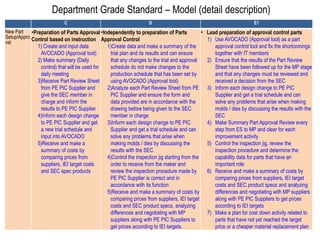

This document provides grade standards for suppliers in different roles. For the Model role, it outlines responsibilities at different grade levels for tasks related to new part planning, mass production preparation, setup/approval, and production enforcement. At higher grades, individuals are expected to take more independent action, lead activities, and identify cost improvements for new parts and the production process. The document provides detailed descriptions of expected duties within each task area to clarify role expectations at each grade level.

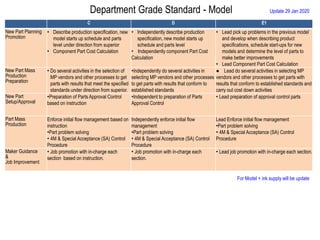

![A B C D E1

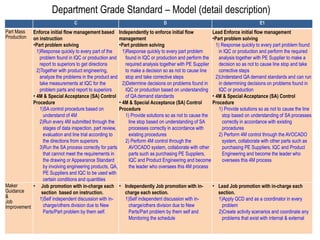

1. Inspection

multi stage

•Inspect

multi

stage of

ES/MP part

based on

instruction

•Report if

there is

abnormality

1. Daily arrangement

Man Power for 4M

change

•Arrange man

power to reach

daily target

•Judge 4M change

in daily operation

2. Inspection of all

stages of the in-

charge area

3. Manpower and

Process control of

the in-charge stages

4. Guide to junior OPR

•Inspect multi

stage of ES/MP

Parts based on

instruction

•Report if there is

abnormality

•Check jig and tool

before inspection

(Template, Auto

program)

1. Check daily inspection

process refer to the Standard.

•Confirm setting of all

necessary items (Man,

Parts, etc.) for inspection to

follow Production Plan.

2. Daily arrangement Man

Power for 4M change

•Arrange man power [4M]

daily or big change [4M]

•Arrange plan if any

abnormality (Rework

/Return /Dispose parts)

3. Identify and solve problem

in daily inspection process

(within standard)

•Inspection procedure

implementation

[Production operation,

quality rule] to achieve

inspection plan

•Report the ES part

measurement output in the

Dept. scope

•Treatment abnormal lot to

ensure customer

(production) operation.

•Guide and coach training

to lower level

•Become an Example (in 5S,

MORAL-UP)

•Involved in the KAIZEN

team

1. Check and analyze issues of

inspection process, review and

improve Standard

•Review, revise operation

standard to improve productivity

(effective, accurate inspection &

no stop line

•Arrange guarantee system

(FILTERING SYSTEM)

2. Inspection process standard

improve

•Arrange plan and carry out

ES/MP part inspection based on

new mod el schedule.

•Communicate ES/MP

measurement part problems

with Part Engineering to make

plan improvement short term

3. Independently, define and set up

action item to issue of of inspection

process.

4. Do total promotion of theme or

scope in-charge

•Coordinate with the relevant

Dept. if there is abnormality /

URGENT Case (Stop line, OQC

Defect)

•Feedback to vendor, follow up

to parts eng if any abnormality

•Involved projects to achieve

Dept plan

1.Check analyze requirement of overall inspection

operation (including new model)

2.Check analyze issue of overall inspection

operation (layout, Man Power allocation ) of existing

model

• Make daily report [achievement progress,

quality condition, reporting problem finding and

short improvement]

•Review capacity and make improvement plan

for inspection

•Set up activity/new model/improvement for

short term

3. Set up plan of overall operation of new model

for IQC IEI-level

4. Set up plan of improvement/ optimization/

reformation of overall operation of existing model

for IQC IEI-level

•Arrange and set up new model [plan operation

and implementaion]

•Review weak point during New model

arrangement

•Set up training for member

•Become an Example (in 5S, MORAL-UP)

•Leader in the KAIZEN team

•Planning, controlling the project according to

achieve Dept Action plan

5. Innovation to achieve ideal figure for IQC IEI-

level (new & existing model operation)

•Do job innovation with use PDCA rule to make

efficiency and productivity up for IQC level.

•Optimize inspection operation, improve

efficiency for IQC level ((supplier improvement

on inspection process/guarantee method)

•Lead activity following to DAP (Control the

work of ES measurement parts according to the

target schedule.)

Department Grade Standard - IQC Update 05 Feb 2020](https://image.slidesharecdn.com/partsengineeringgradestandard-230922074704-f9e37e67/85/Parts-Engineering-Grade-Standard-pptx-11-320.jpg)