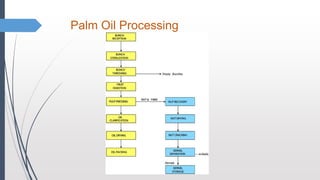

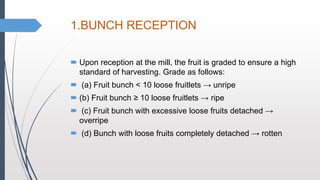

This document discusses palm oil, including its origins, production process, and uses. It begins by explaining that oil palm trees are native to West Africa and can produce up to 10 tons of fruit per hectare annually. It then outlines the seven step process of palm oil production: bunch reception, sterilization, threshing, digestion, oil extraction via screw pressing, clarification, and refining. The final steps remove impurities to produce a stable, edible oil that constitutes 34% of global edible oil production due to palm oil's high yields and saturated fat content.