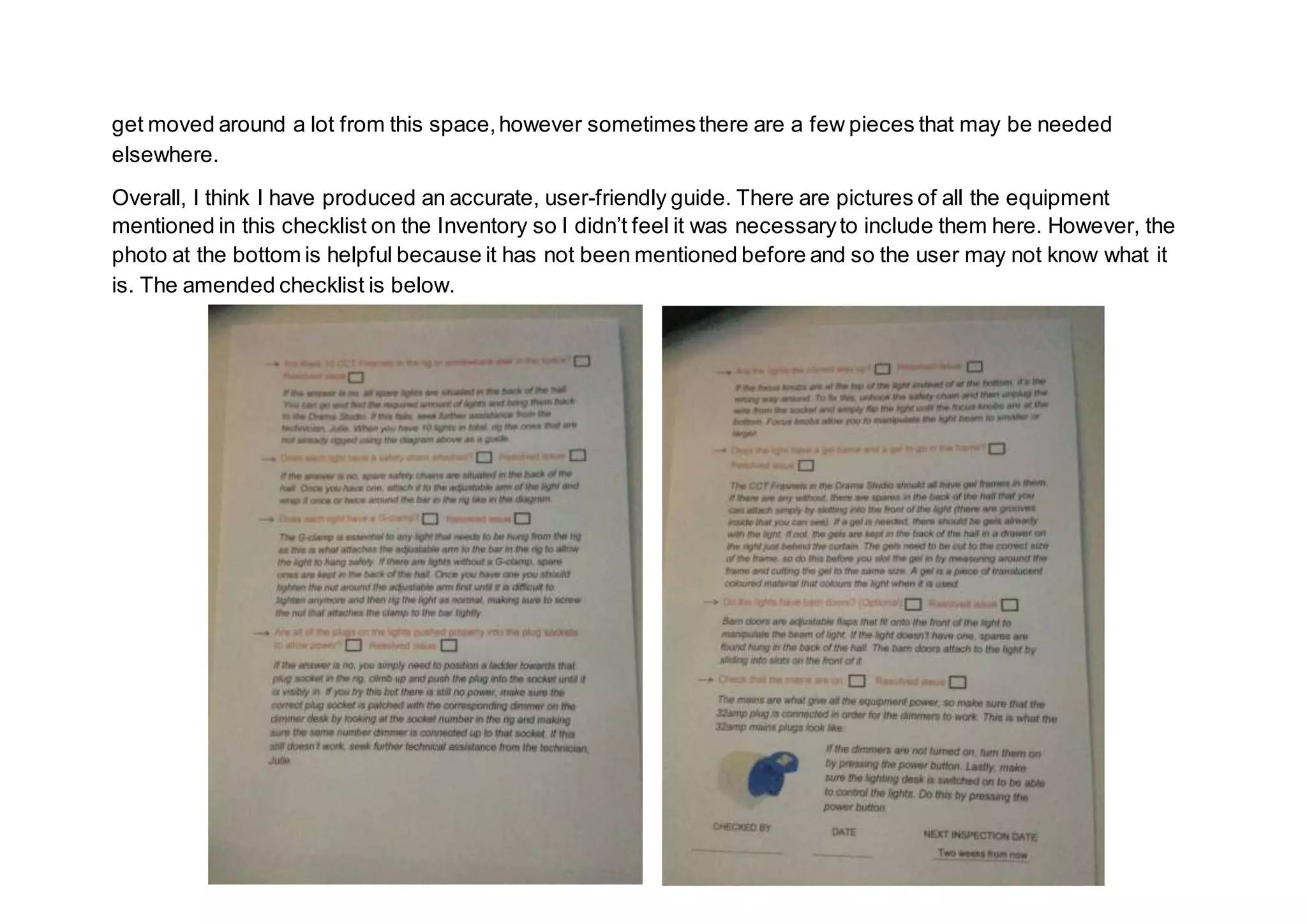

The document describes changes made to a checklist to make it more user-friendly. It details several issues with the original checklist and improvements implemented in an amended version. Specifically, it notes that barn doors are optional, a "resolved issue" box was added, unplugging rather than fully de-rigging lights was sufficient, font colors were adjusted to distinguish questions from solutions, and signature/date fields were included for accountability of equipment checks. The amended checklist implementing these changes is provided to better guide users through equipment inspections.