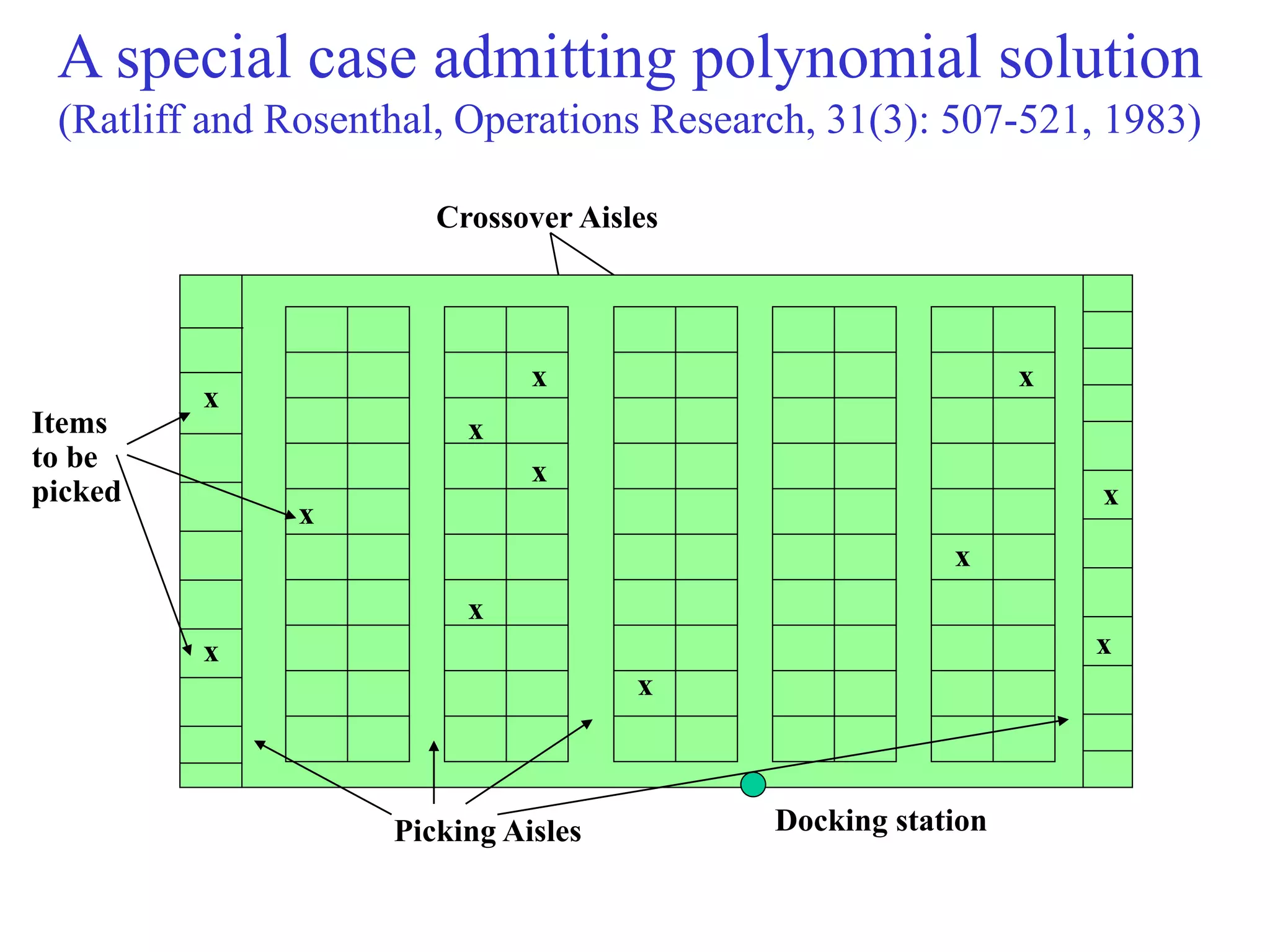

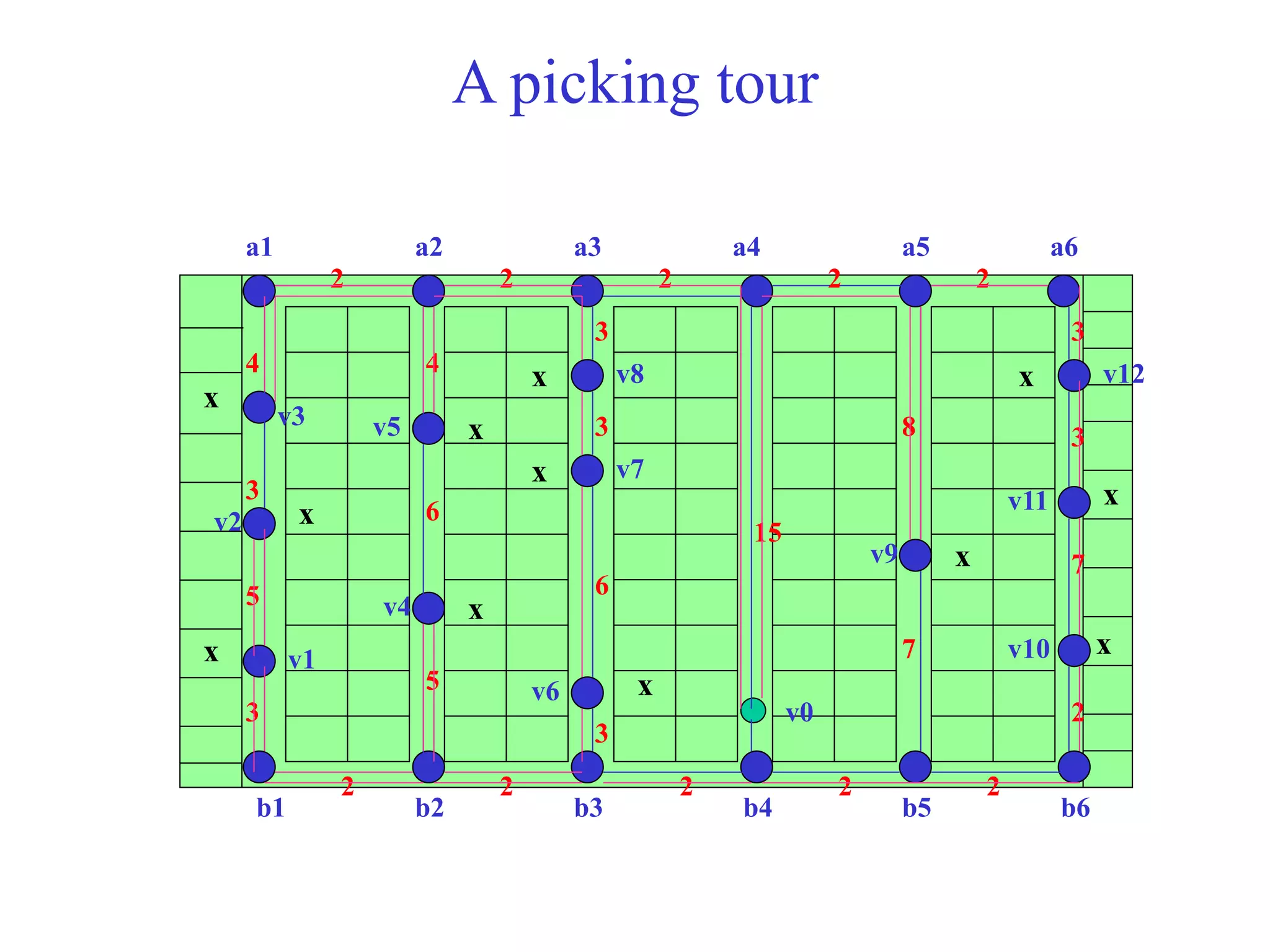

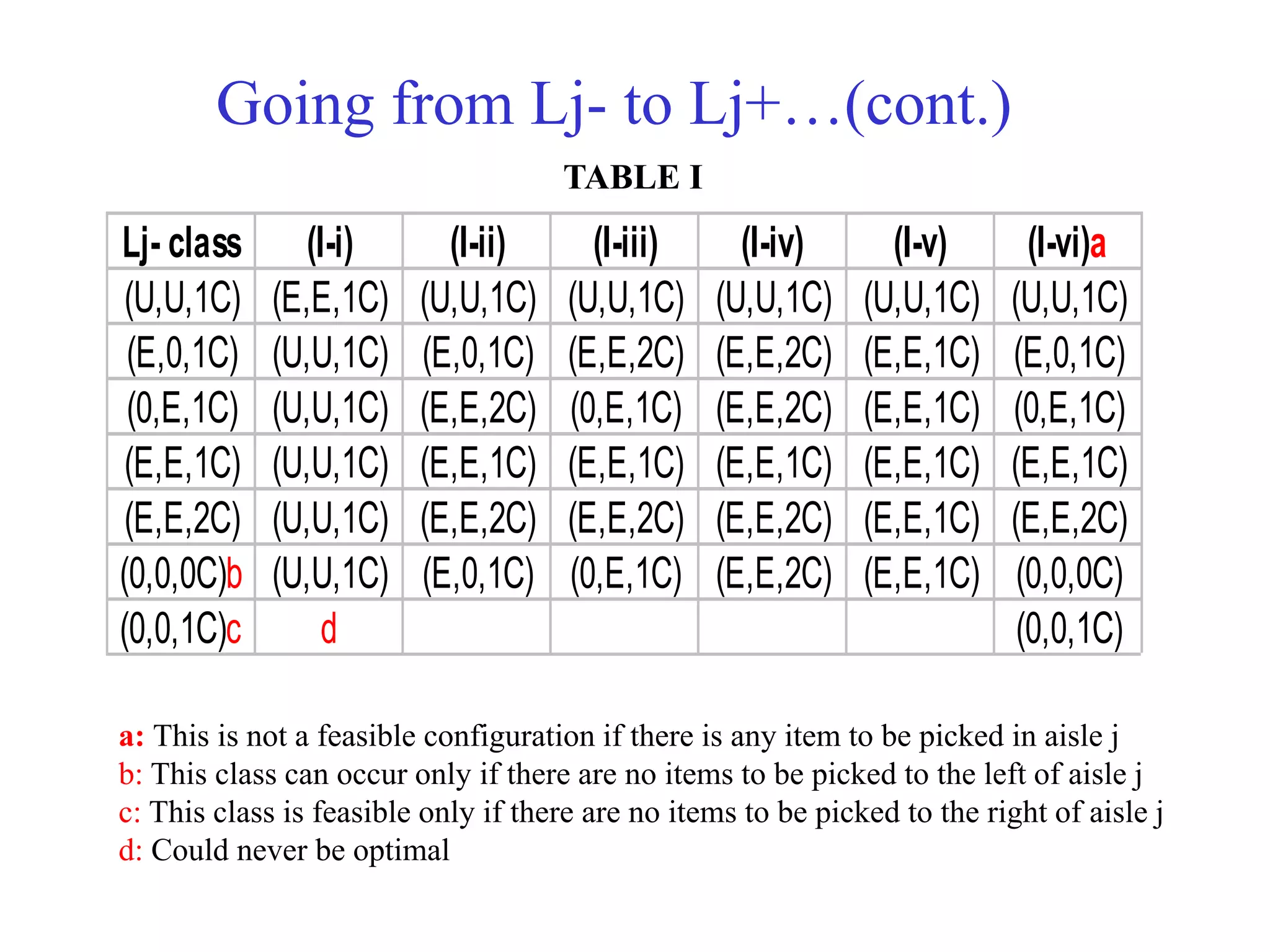

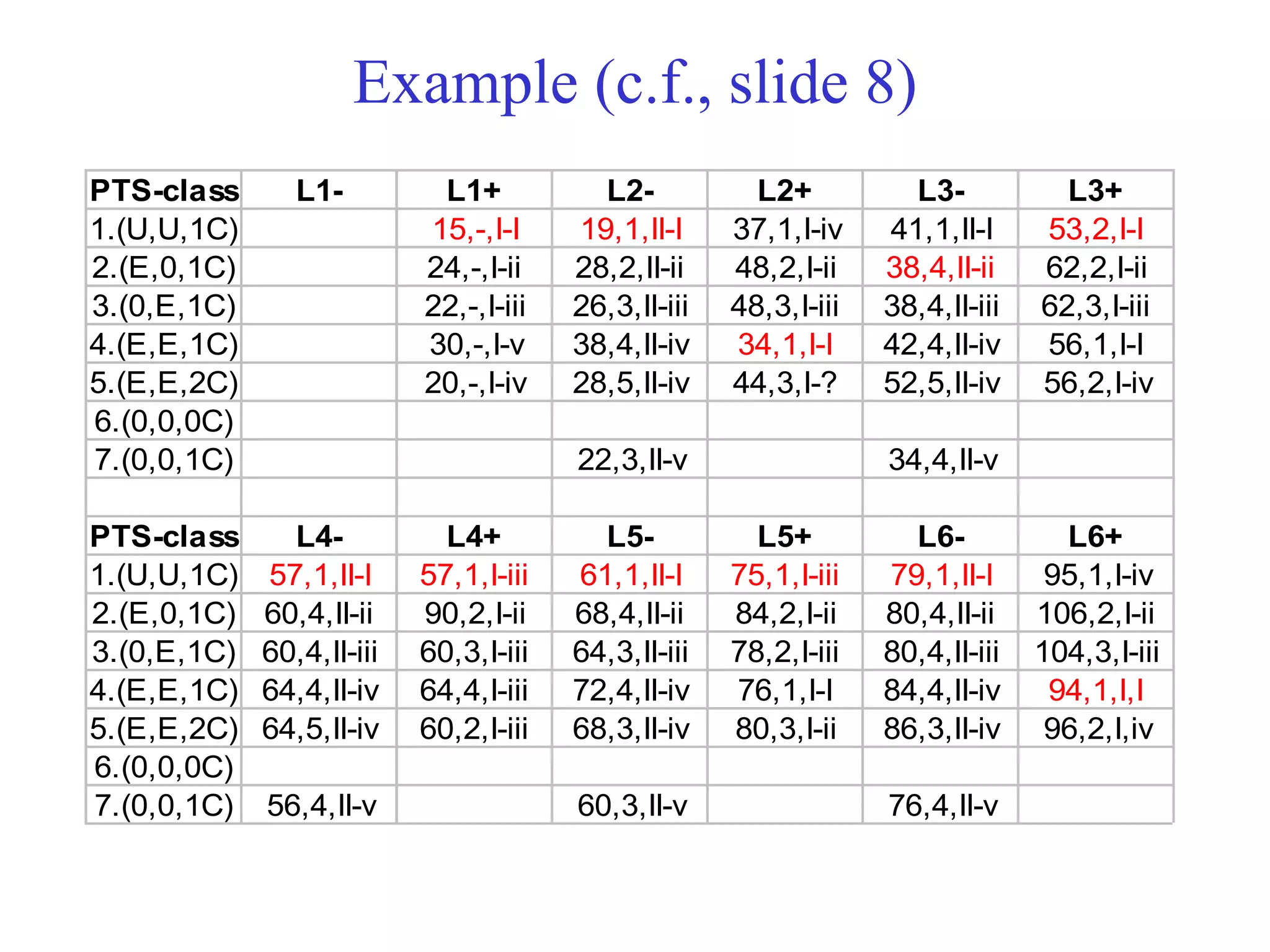

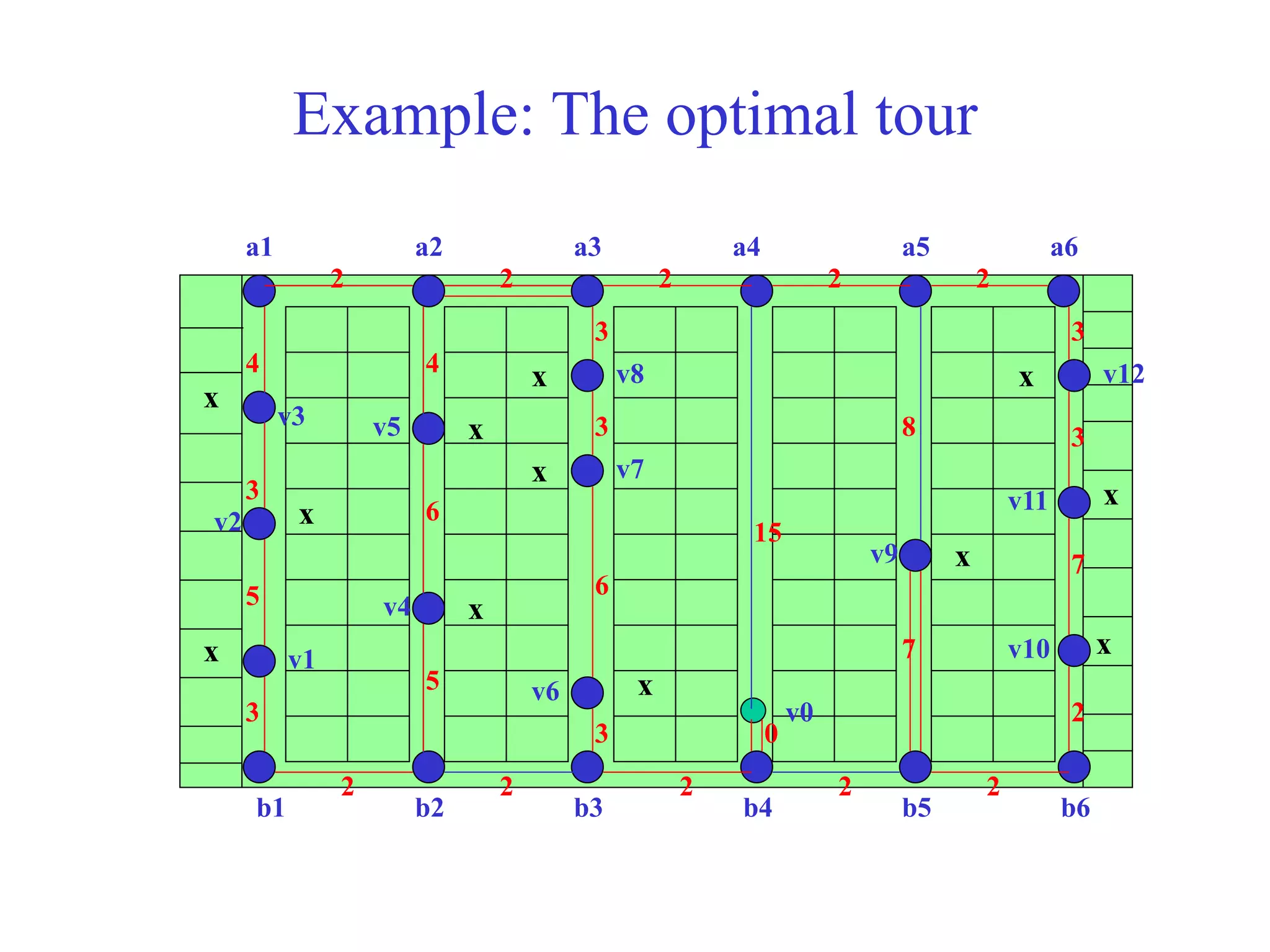

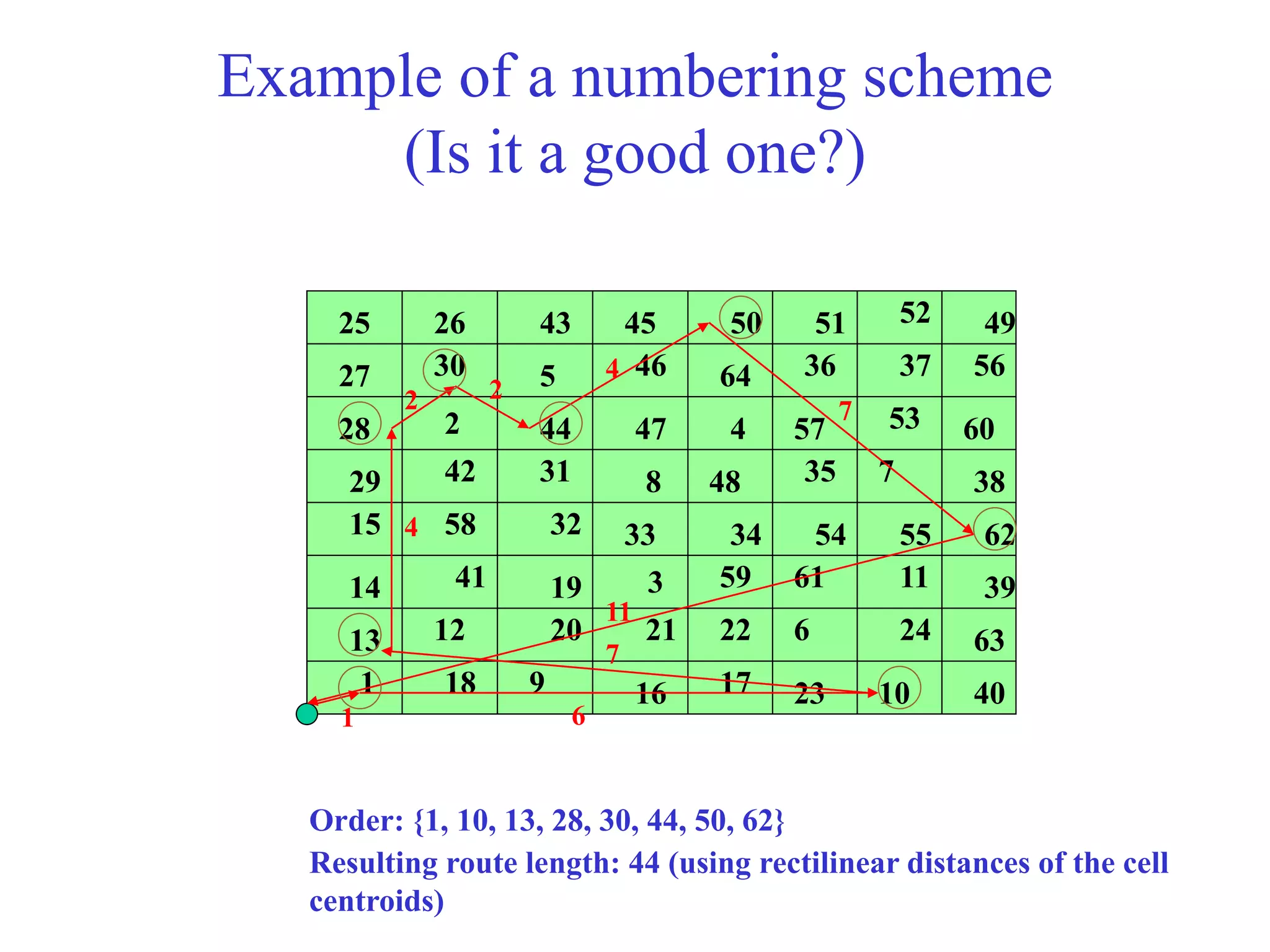

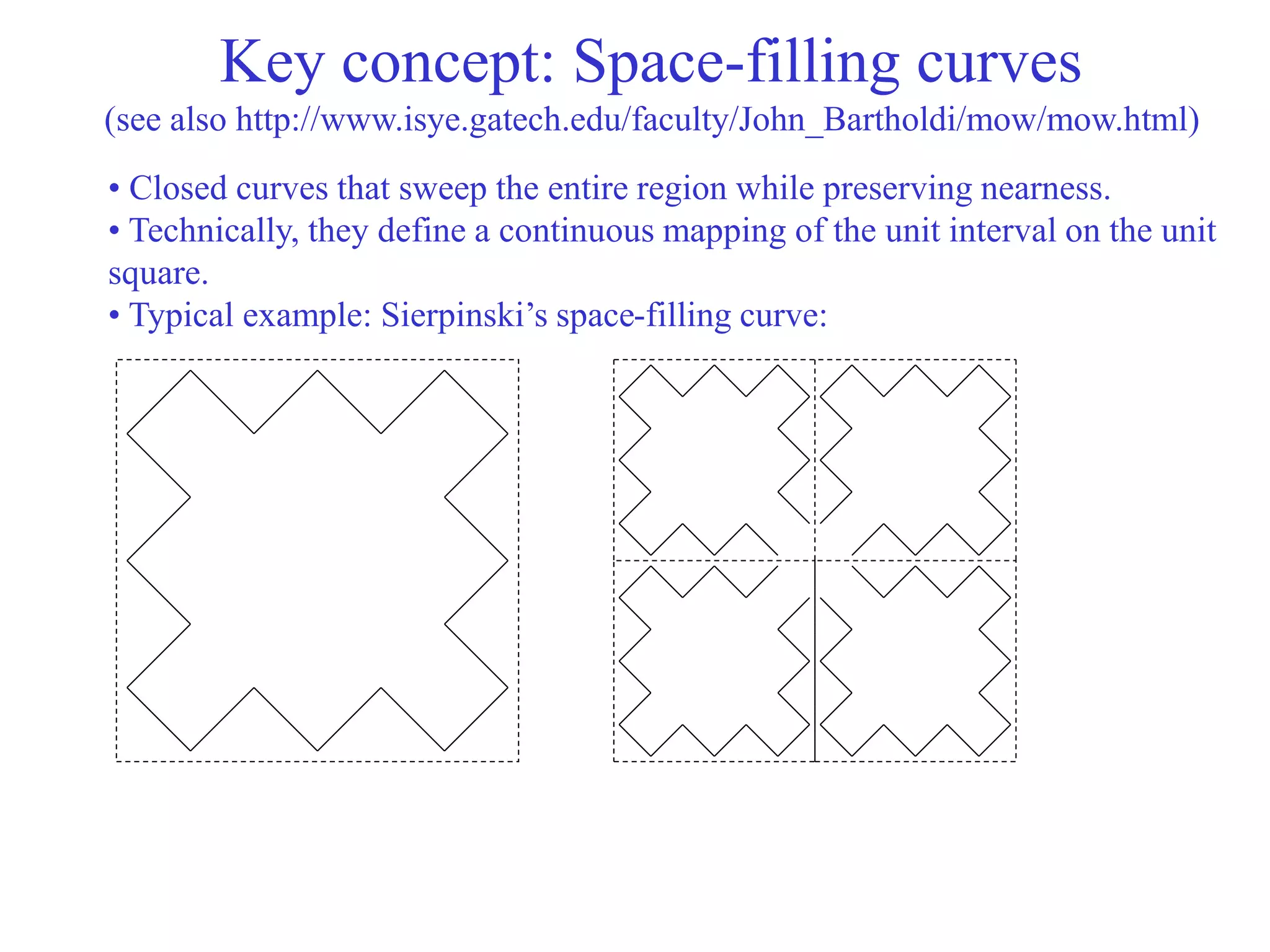

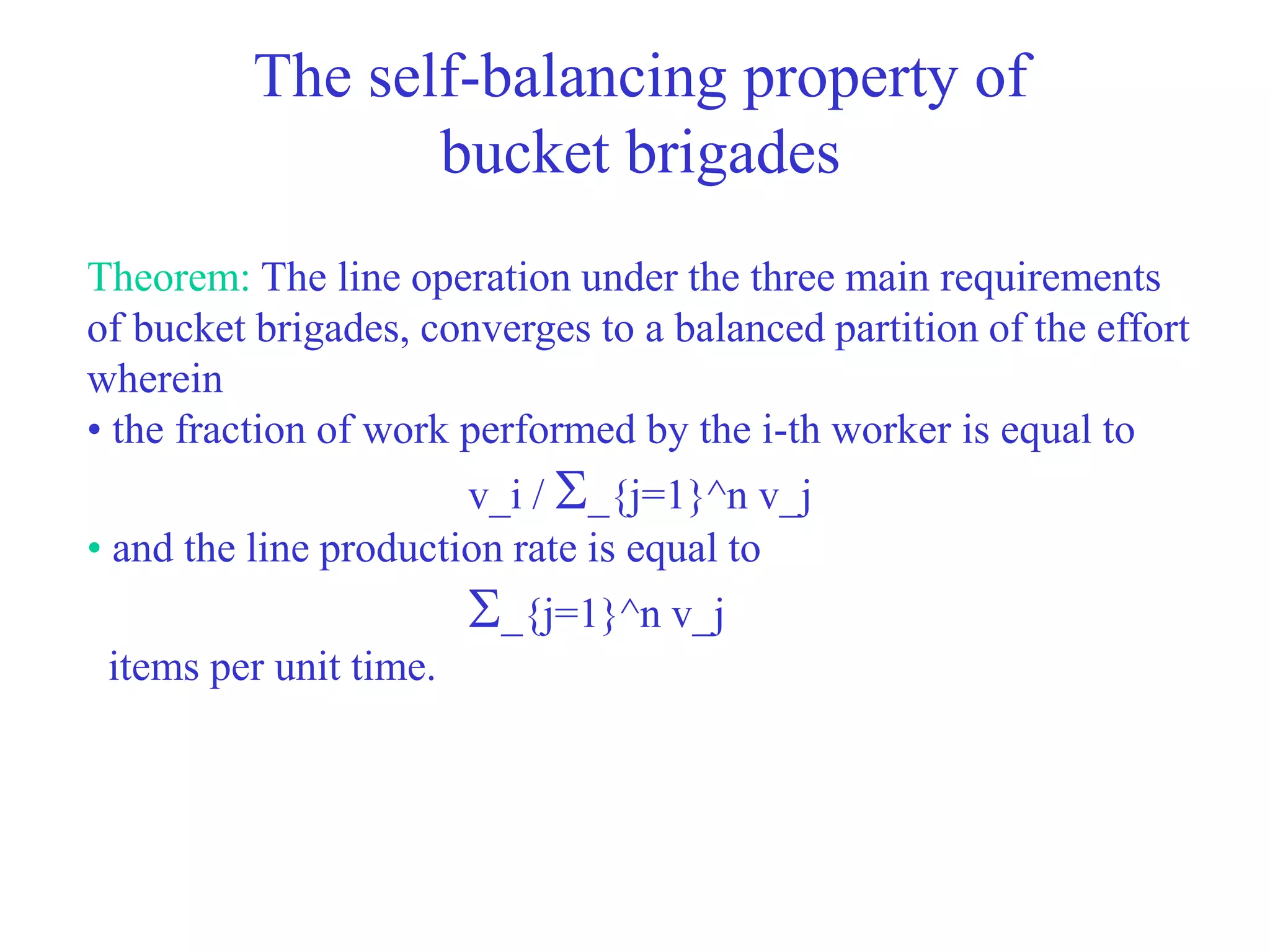

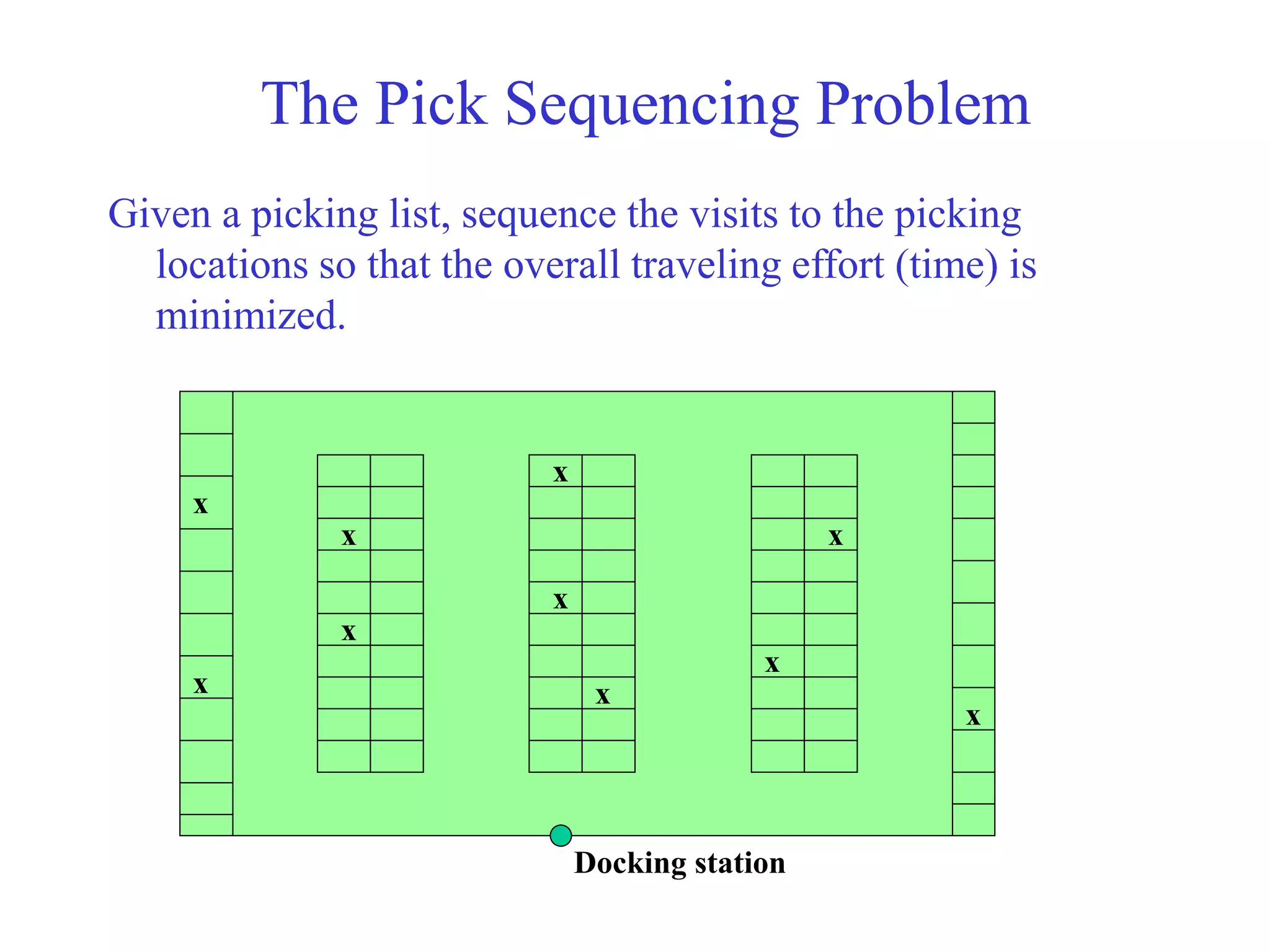

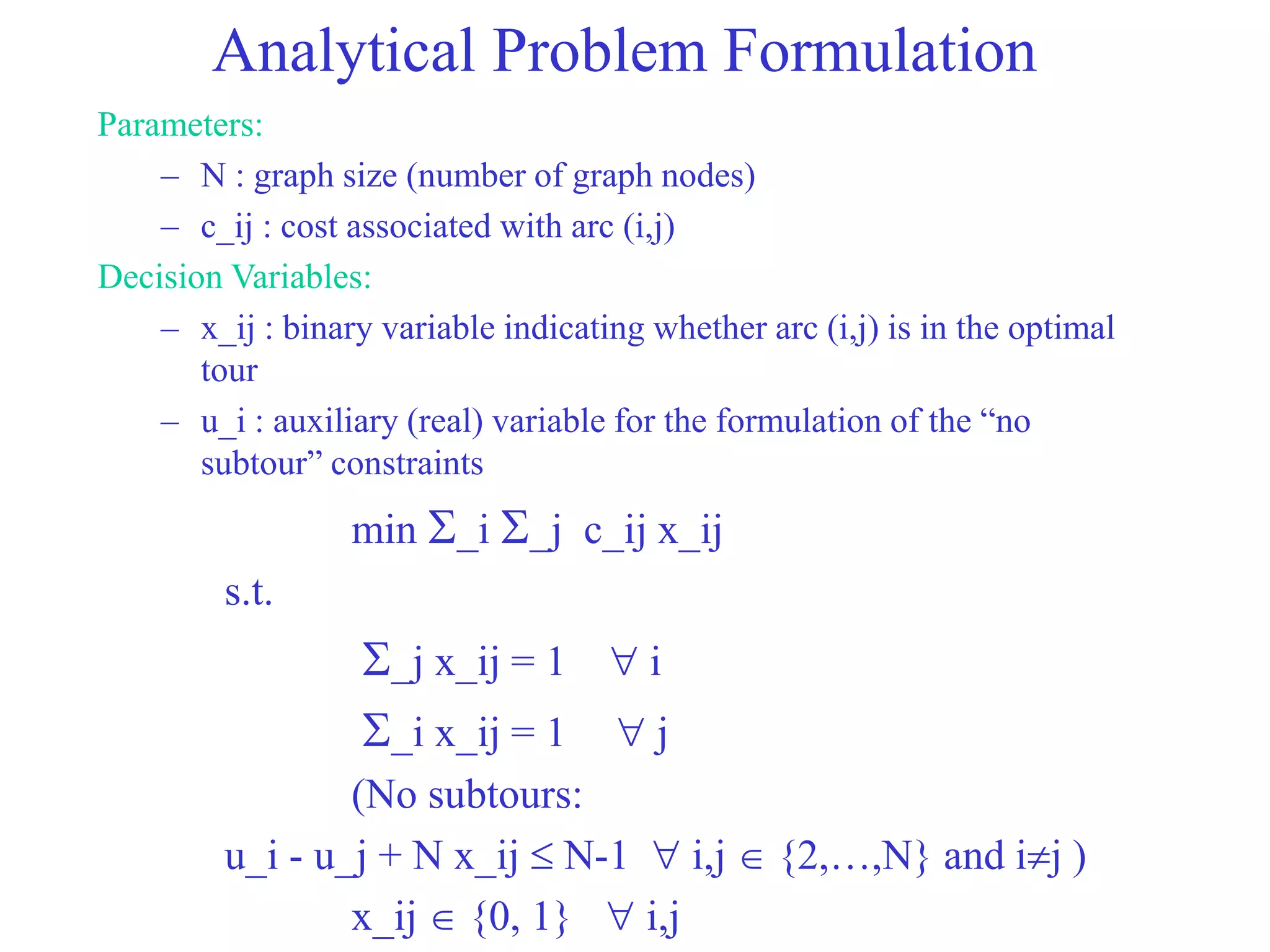

The document discusses various policies for order picking, including pick sequencing, batching, and zoning. It describes the pick sequencing problem as analogous to the Traveling Salesman Problem (TSP) of finding the shortest route that visits all locations. It provides an analytical formulation of the TSP as a minimization problem with constraints. It also describes several heuristics for approximating solutions to the TSP, including the closest insertion algorithm. A special case admitting a polynomial-time solution involves a grid-like warehouse layout. Overall, the document outlines different approaches to modeling and solving the pick sequencing problem programmatically to minimize travel time.

![The closest insertion algorithm:

A TSP heuristic (symmetric version)

Initialization:

S_p = <1>; S_a = {2,…,N}; c(j) = 1, j {2,…,N}; n=1;

While n < N do

n = n+1;

Selection step:

j* = argmin_{j S_a} {c_{j,c(j)}};

S_a = S_a {j*};

Insertion step:

i* = argmin_{i =1}^|S_p| {c_{[i],j*} + c_{j*,[i mod |S_p|+1]}

- c_{[i],[i mod |S_p|+1]}};

S_p = < [1],…,[i*], j*, [i*+1],…,[n]>;

j S_a, if c_{j,j*} < c_{j,c(j)} then c(j) = j*;

Remarks: 1. [i] denotes the node at i-th position of the constructed sub-tour.

2. If the distances are symmetric and satisfy the triangular inequality, the cost of

the solution provided by this heuristic is no worse than twice the optimal cost.](https://image.slidesharecdn.com/order-picking-policies-221129195812-ee75d105/75/Order-Picking-Policies-ppt-6-2048.jpg)