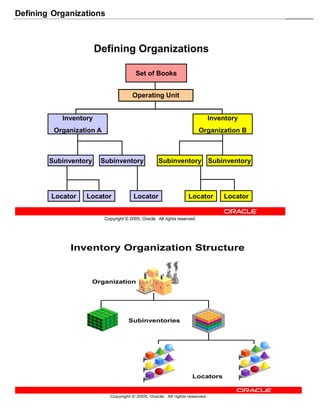

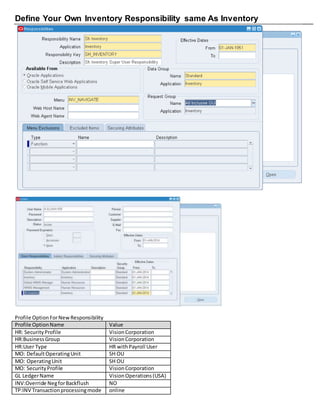

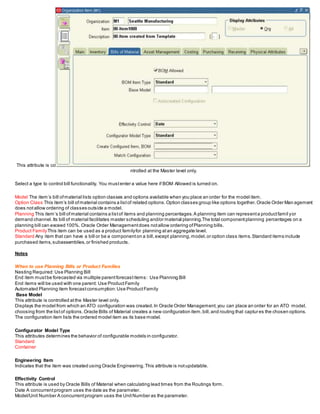

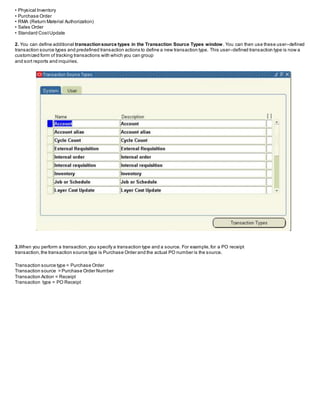

Oracle Inventory is one of Oracle's enterprise applications products that enables companies to define part numbers, model organization structures, track perpetual inventory, maintain accurate on-hand balances, plan material replenishments, and forecast anticipated demand. It provides several key flexfields including system items, item catalogs, item categories, stock locators, and account aliases. The flexfields must be designed and configured before implementing inventory functionality in Oracle.

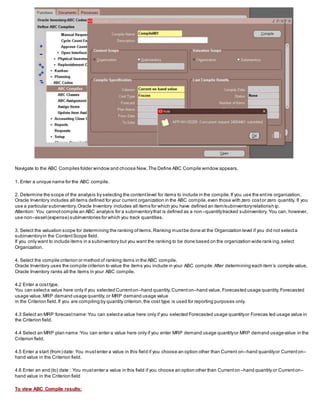

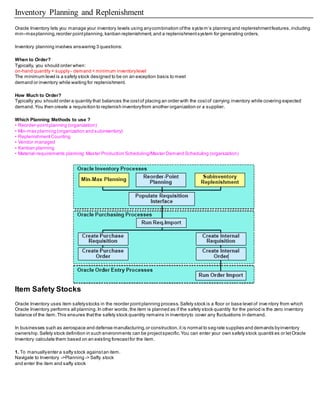

![Reorder Point Planning

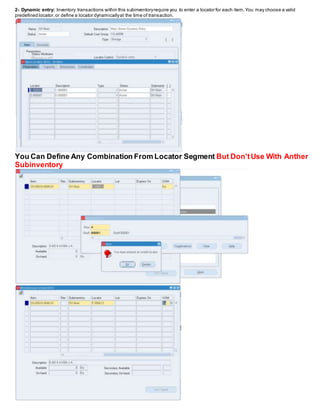

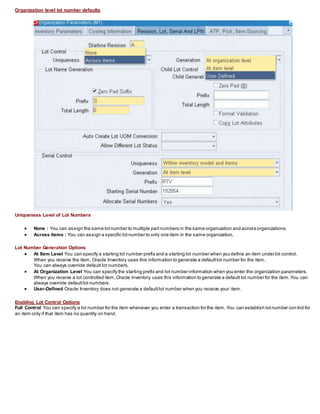

Reorder pointplanning uses demand forecasts to decide when to order a new quantity to avoid dipping into safety stock.

Reorder pointplanning suggests a new order for an item when the available quantity—on–hand quantityplus planned receipts—drops below

the item’s safetystock level plus forecastdemand for the item during its replenishmentlead time.The suggested order quantityis an economic

order quantity that minimizes the total costof ordering and carrying inventory. Oracle Inventory can automaticallygenerate requisitions to

inform your purchasing departmentthata replenishmentorder is required to supplyyour organization.

When the sum ofonhad and planned receipts reaches the pointA( i.e. the reorder point) the system suggests thatwe should create a

requisition (or the system can automaticallycreate) of the value of reorder quantity. So, at the time (PointB) we receives the material in

inventory the total onhand would be at safety stock and after receiptthe total onhand would increase byreorder quantity(EOQ) to C.

Reorder-pointplanning uses the following pieces ofinformation:

• Available Quantity

• Reorder point

• Safety stock

• Item demand

• Replenishment lead time

• EOQ

• Order cost

• Carrying cost

Available Quantity

Its the sum of= Inventory On hand + Quantity on order

Quantity on Order: The sum ofpurchase order,requisition (internal and supplier),and intransitquantities owned bythe orga nization.Quantity

on order represents supplies thatyou have not received in your organization.

Reorder point

Timing of Reorders Reorder when the following is true:

(quantity on hand + quantity on order) < reorder point

where reorder point = safety stock + [(lead time) * (average demand during lead time)]

Safety Stock Safety stock for an item is the quantity of an item that you plan to have in inventory to protect againstfluctuations in demand and

supply.You can enter your own safety stock quantities,or Oracle Inventory can calculate safety stock based on an existing forecastfor the

item.](https://image.slidesharecdn.com/elshayeboracleinventory-141026023527-conversion-gate01/85/Oracle-inventory-R12-Setup-Guide-237-320.jpg)

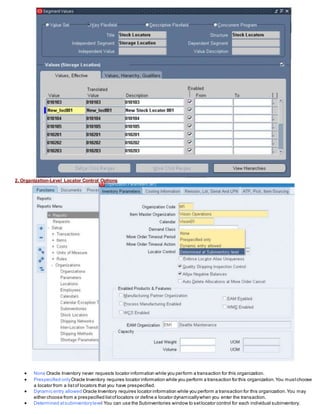

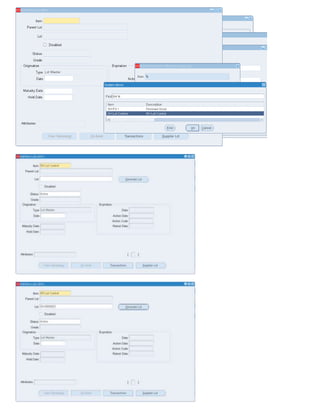

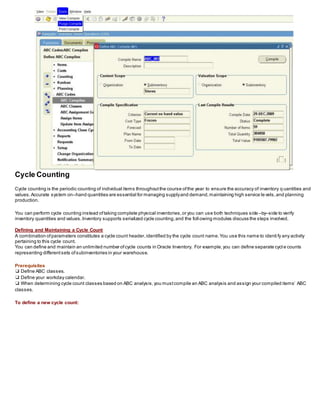

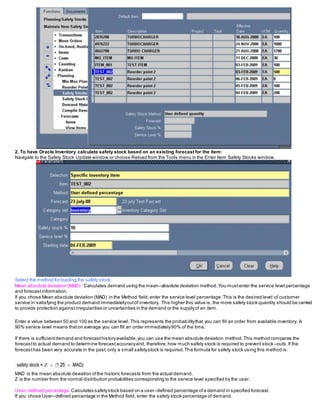

![The economic order quantityis the quantity that minimizes the total costof ordering and storing inventory.

EOQ = SQRT {[2 * (annual demand) * (order cost)]/(carrying cost percent *unit cost)}

Annual carrying cost= carrying cost percent*unitcost

Oracle Inventory calculates annual demand information from the forecast that you provide when you perform reorder pointplanning.

The EOQ increases as demand increases,since the costof carrying a larger order is smaller because the inventory is not carried as long.

EOQ also increases when the costof preparing an order increases.This is to avoid making too manyorders and thus incurring this costmore

often than necessary.On the other hand, the more it costs to carry inventory, the smaller the EOQ since it costs more to carry the excess

inventory.

You can constrain the reorder quantity by specifying the following information for each item:

• Fixed-lot multiplier

• Minimum order quantity

• Maximum order quantity

Order cost

The costassociated in ordering the item.

Carrying cost

The costassociated in carrying the item in inventory.](https://image.slidesharecdn.com/elshayeboracleinventory-141026023527-conversion-gate01/85/Oracle-inventory-R12-Setup-Guide-239-320.jpg)