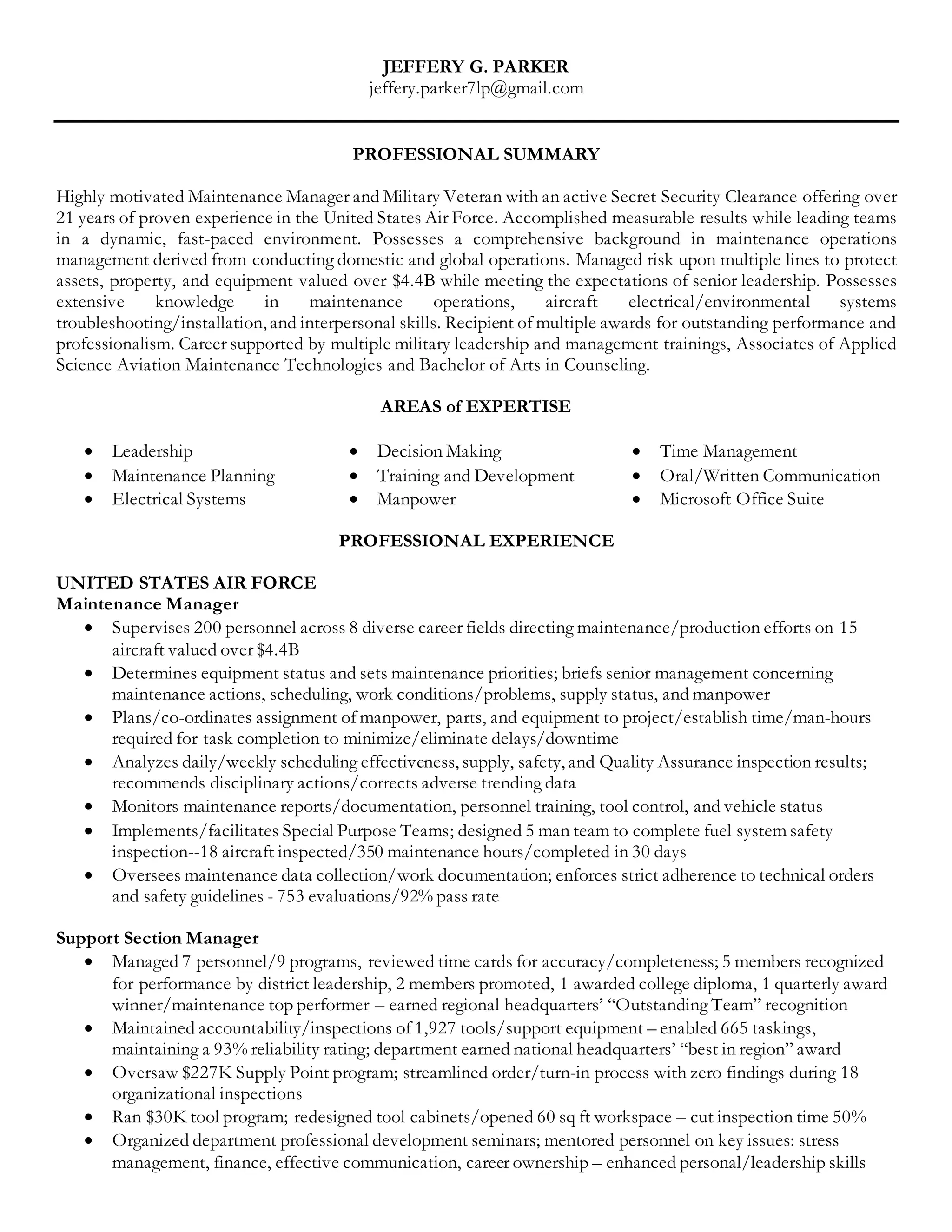

Jeffery Parker is a highly motivated Maintenance Manager with over 21 years experience in the US Air Force. He supervised 200 personnel and managed maintenance of 15 aircraft valued at over $4.4 billion. Parker has extensive expertise in maintenance operations management, aircraft electrical systems troubleshooting, leadership, and training. He holds a Bachelor's degree in Biblical Counseling and an Associate's degree in Aviation Maintenance Technology. Parker has received numerous awards for his outstanding performance and professionalism throughout his military career.