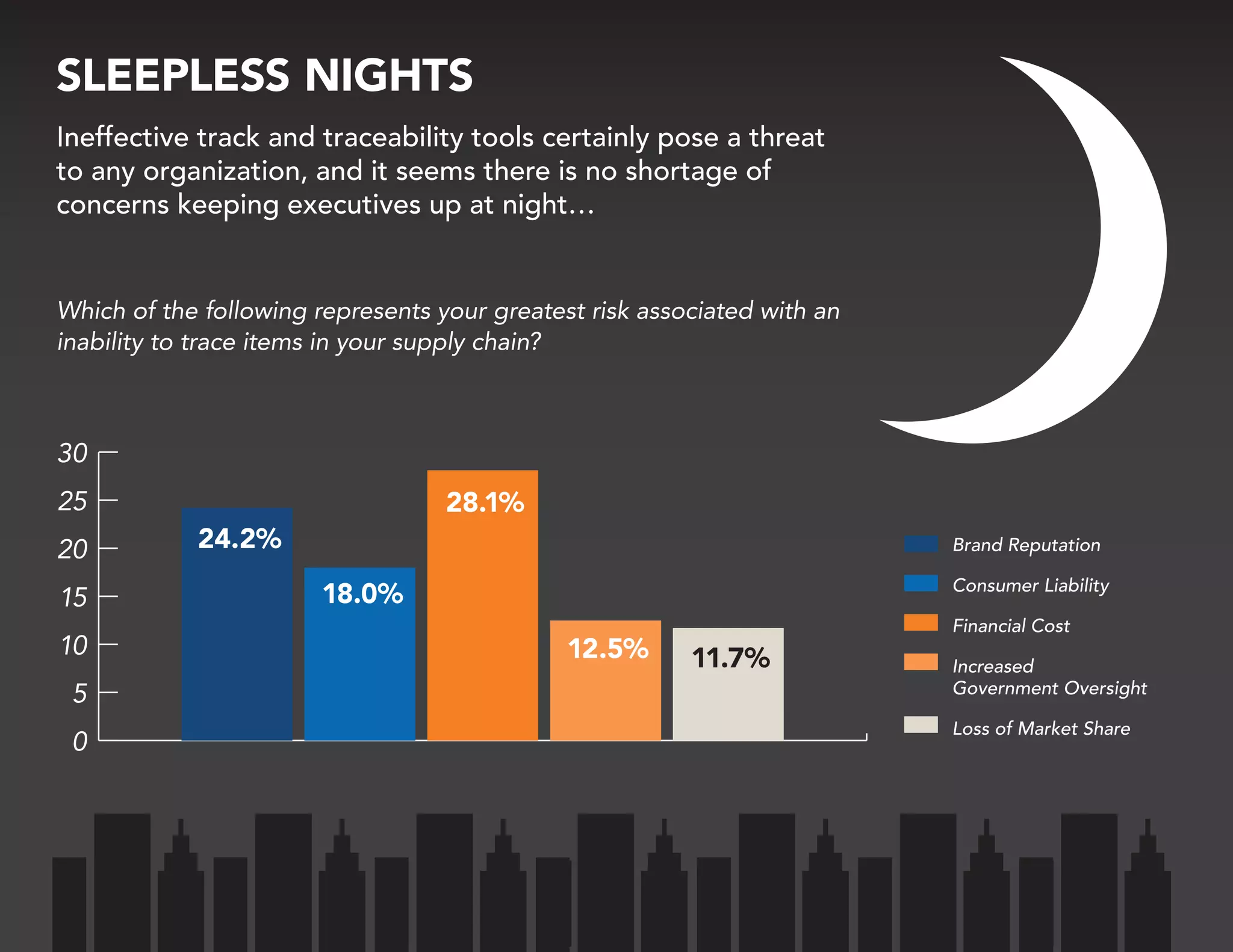

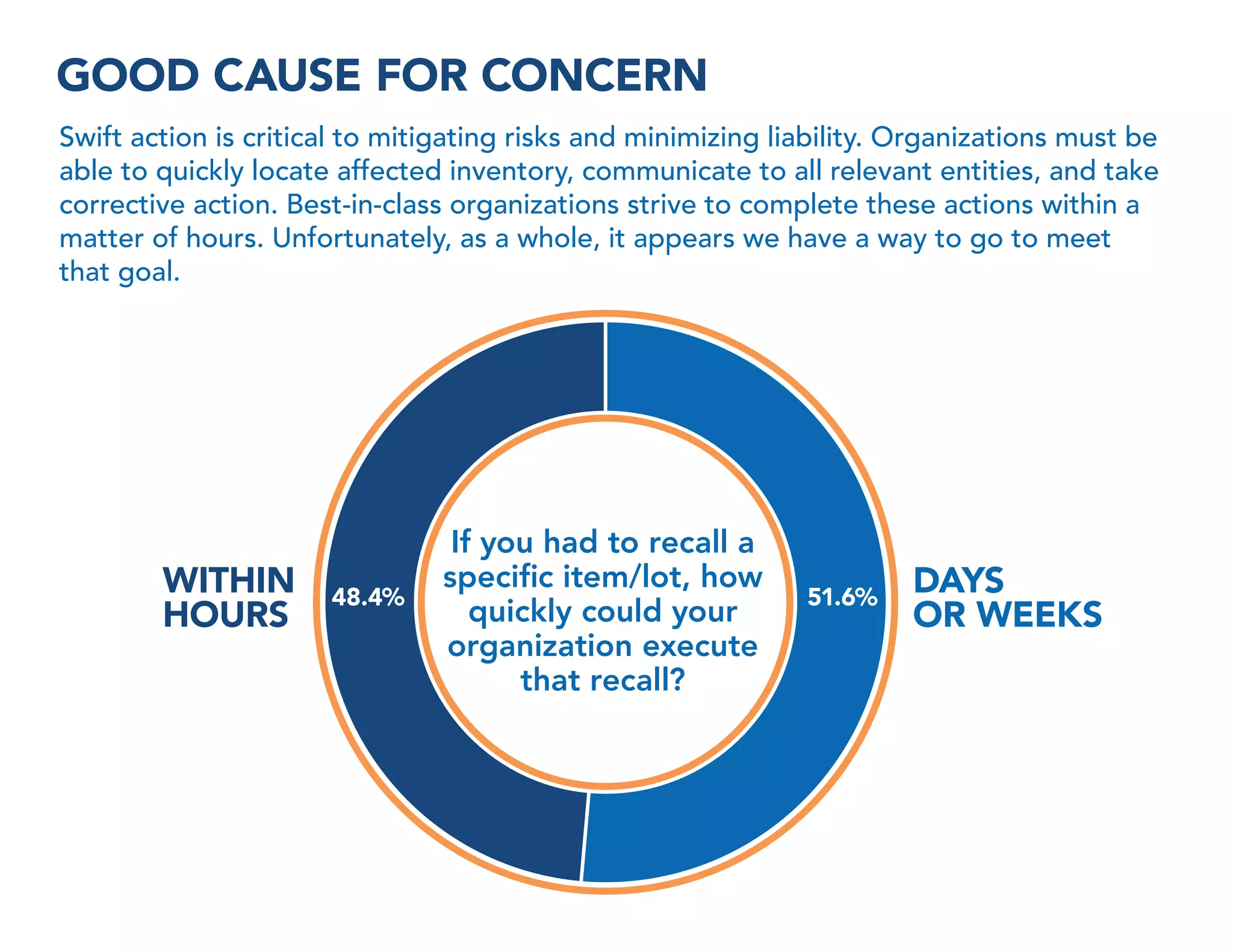

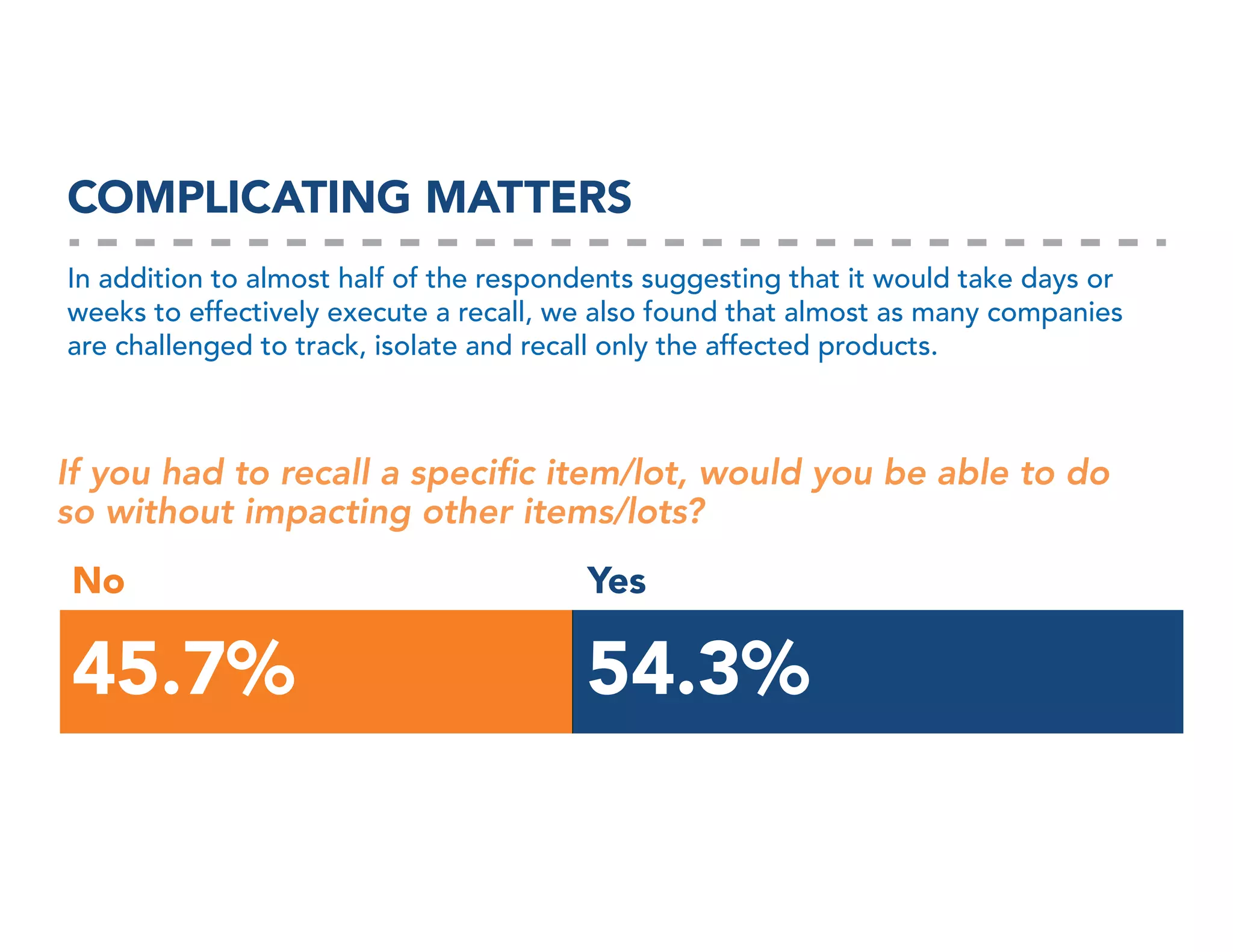

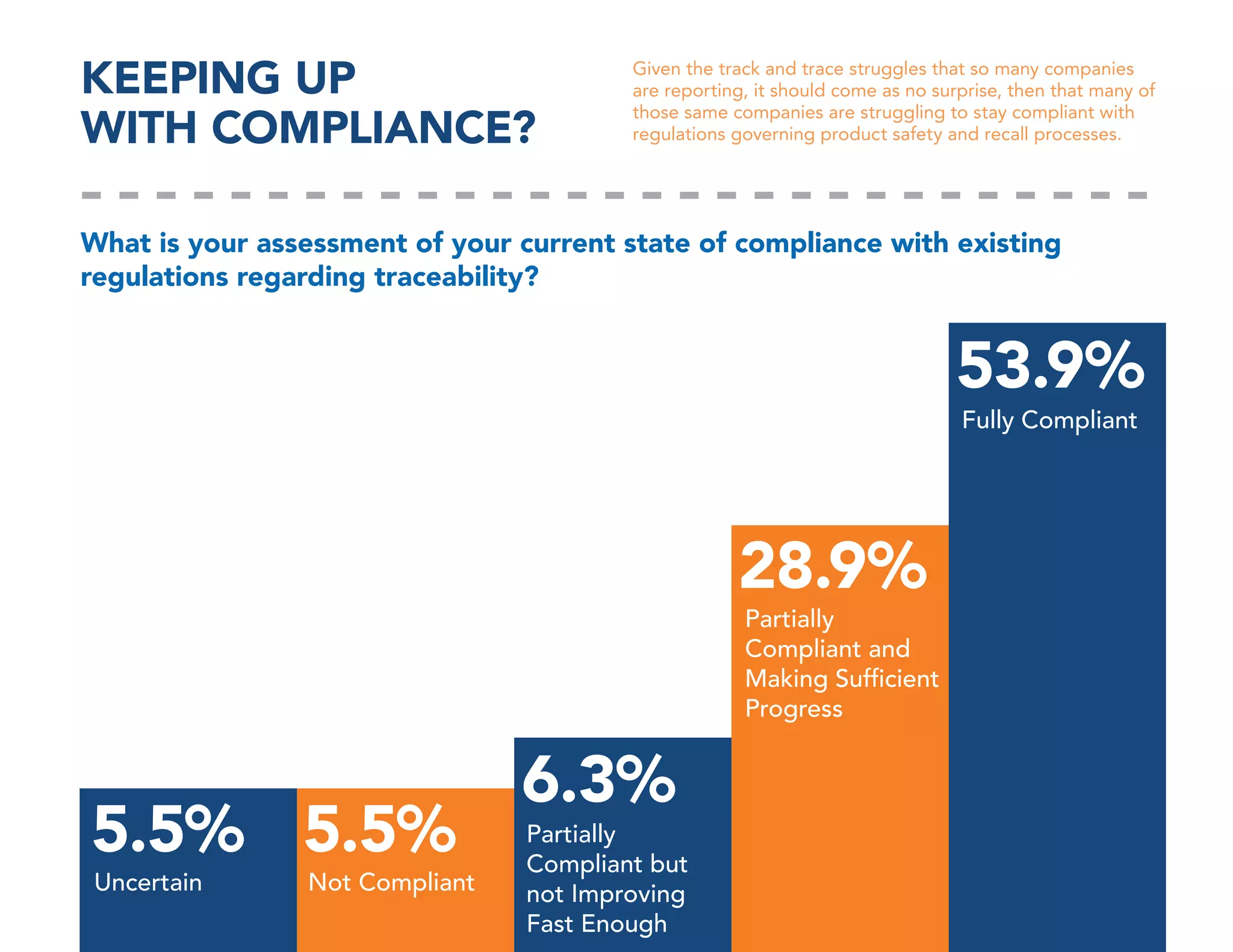

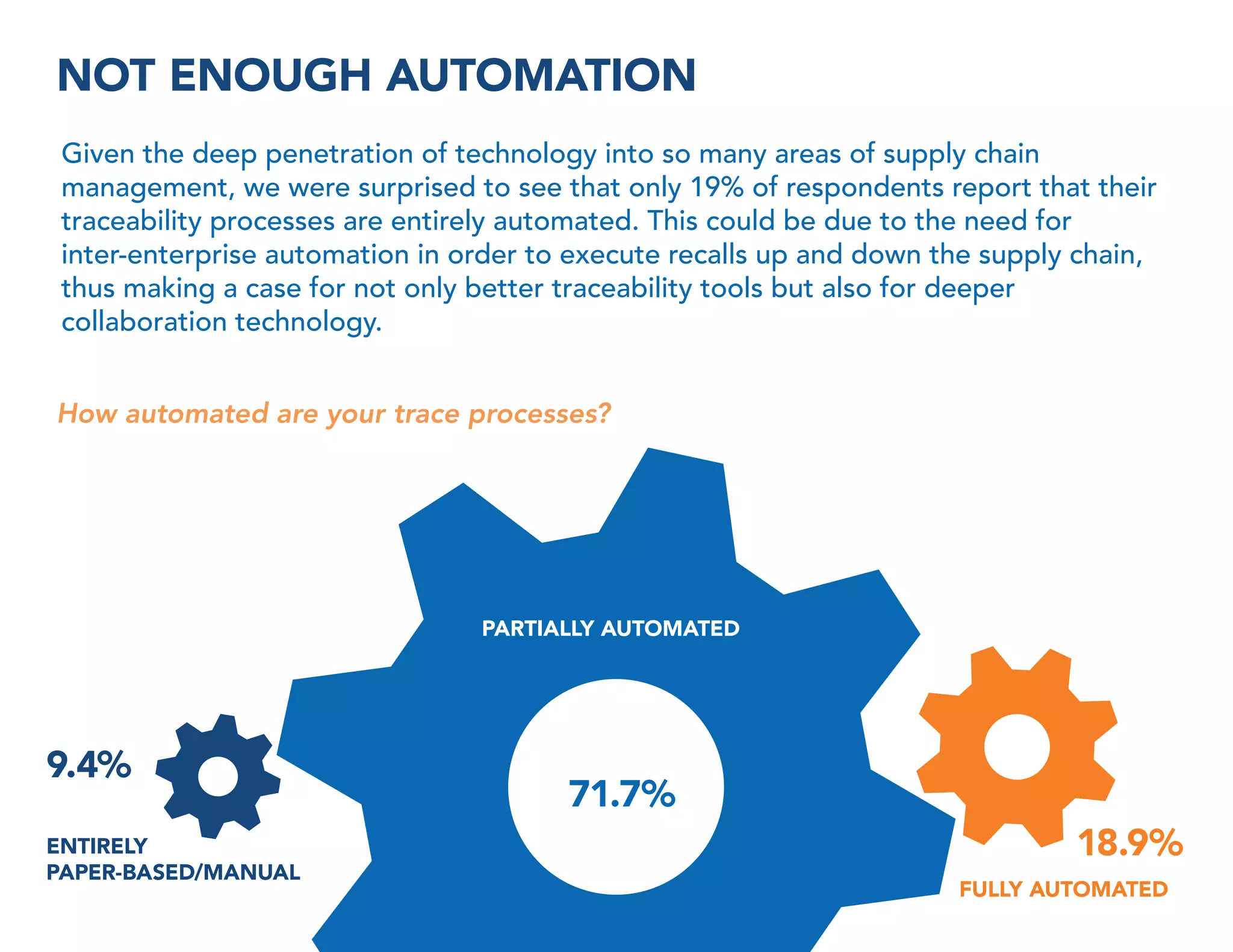

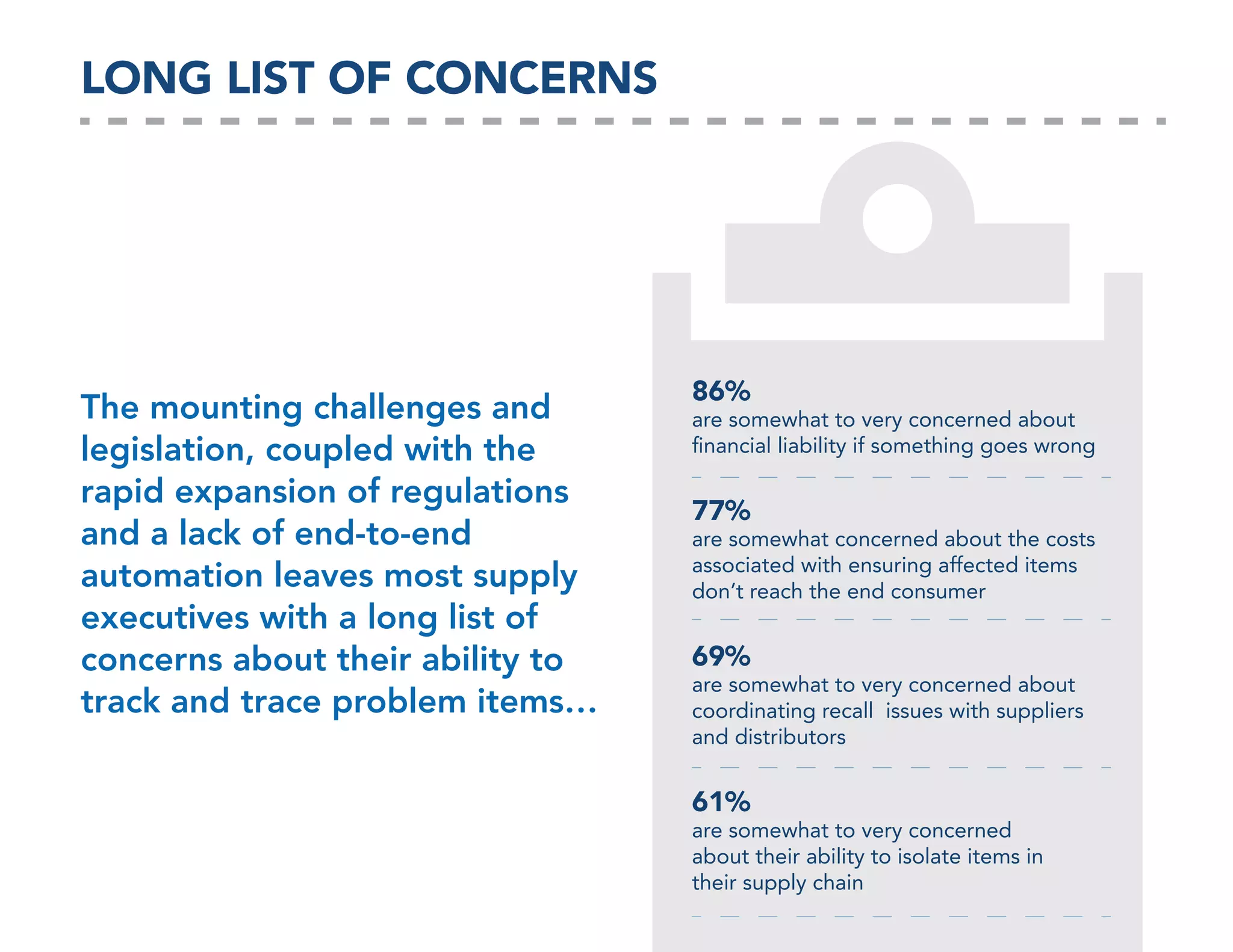

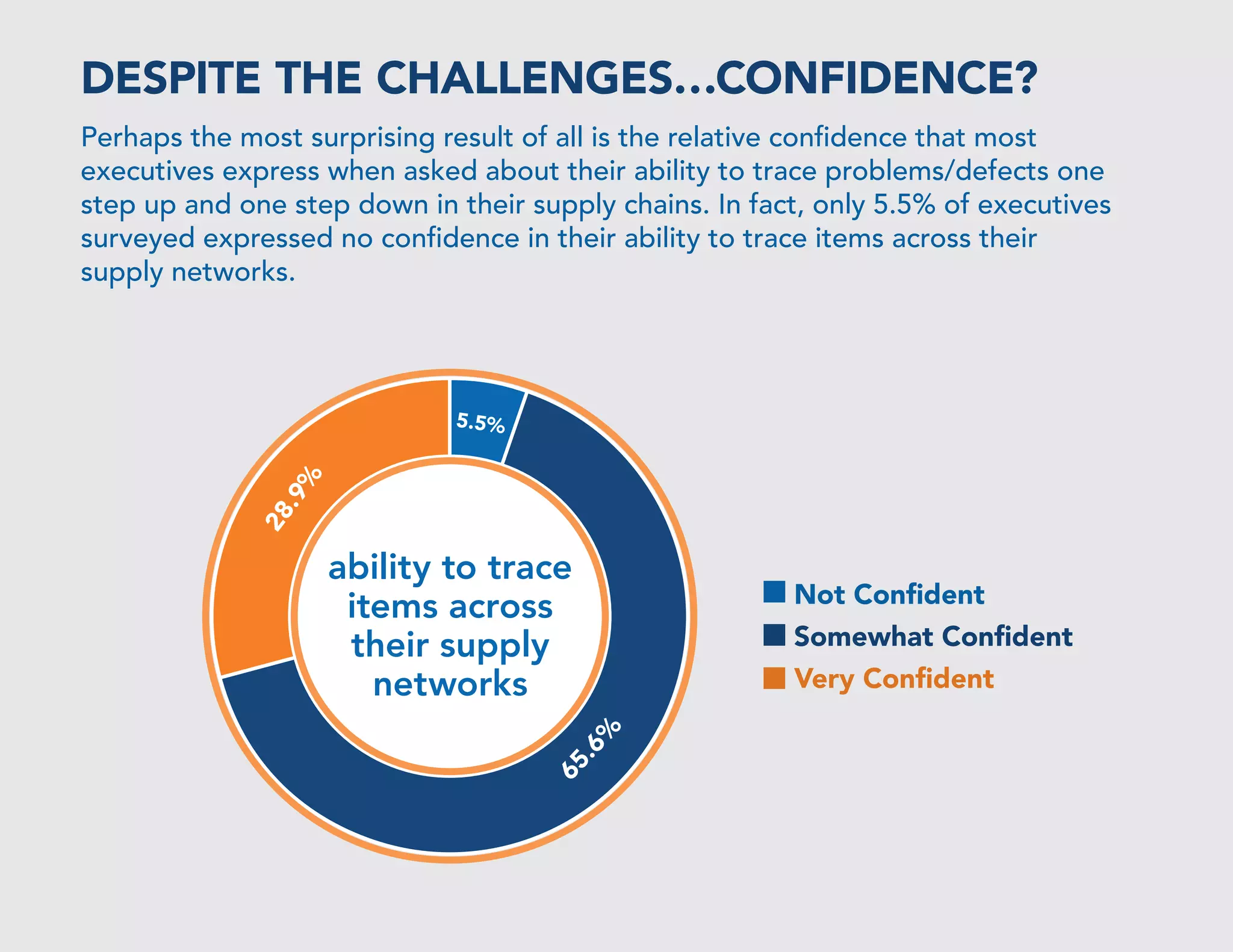

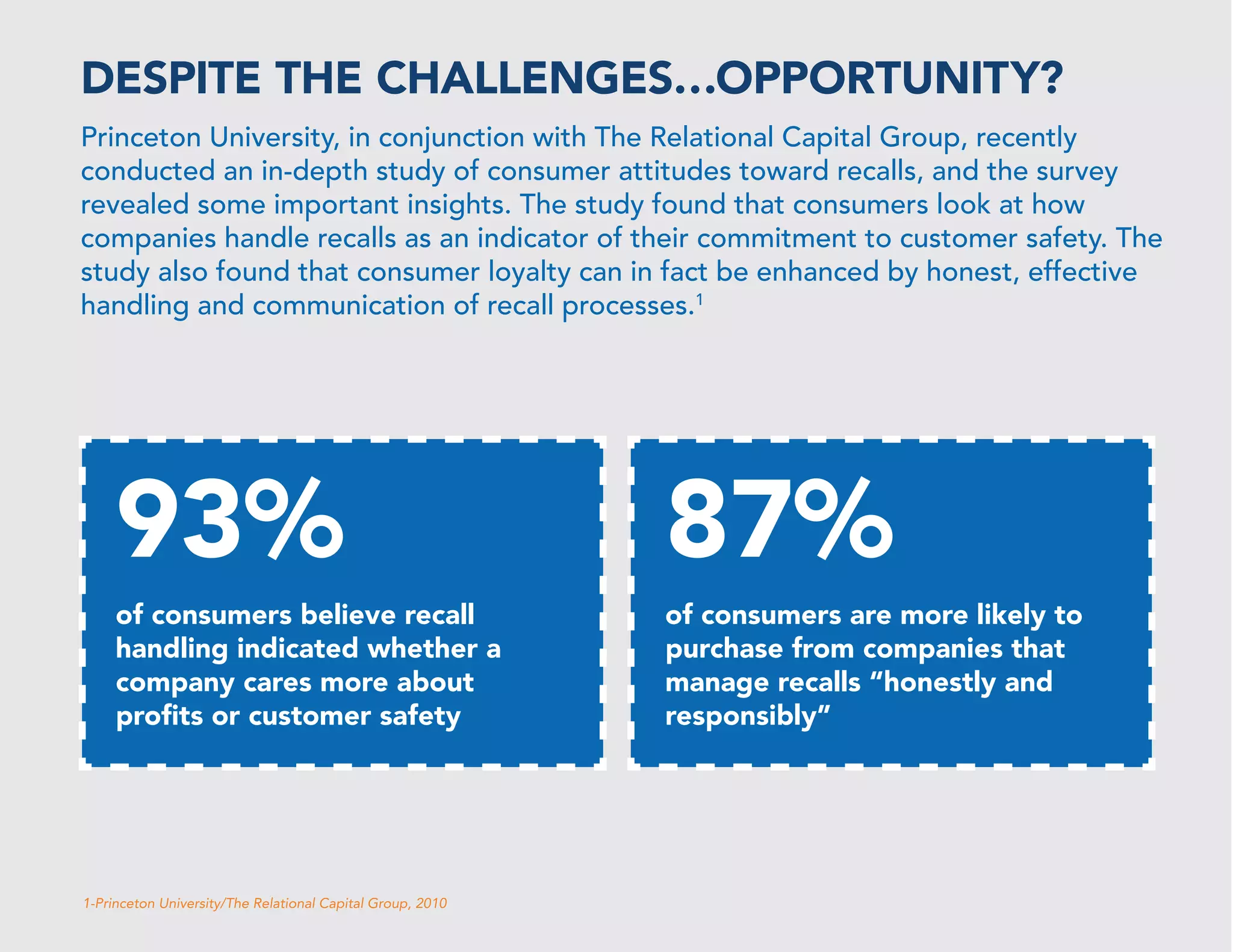

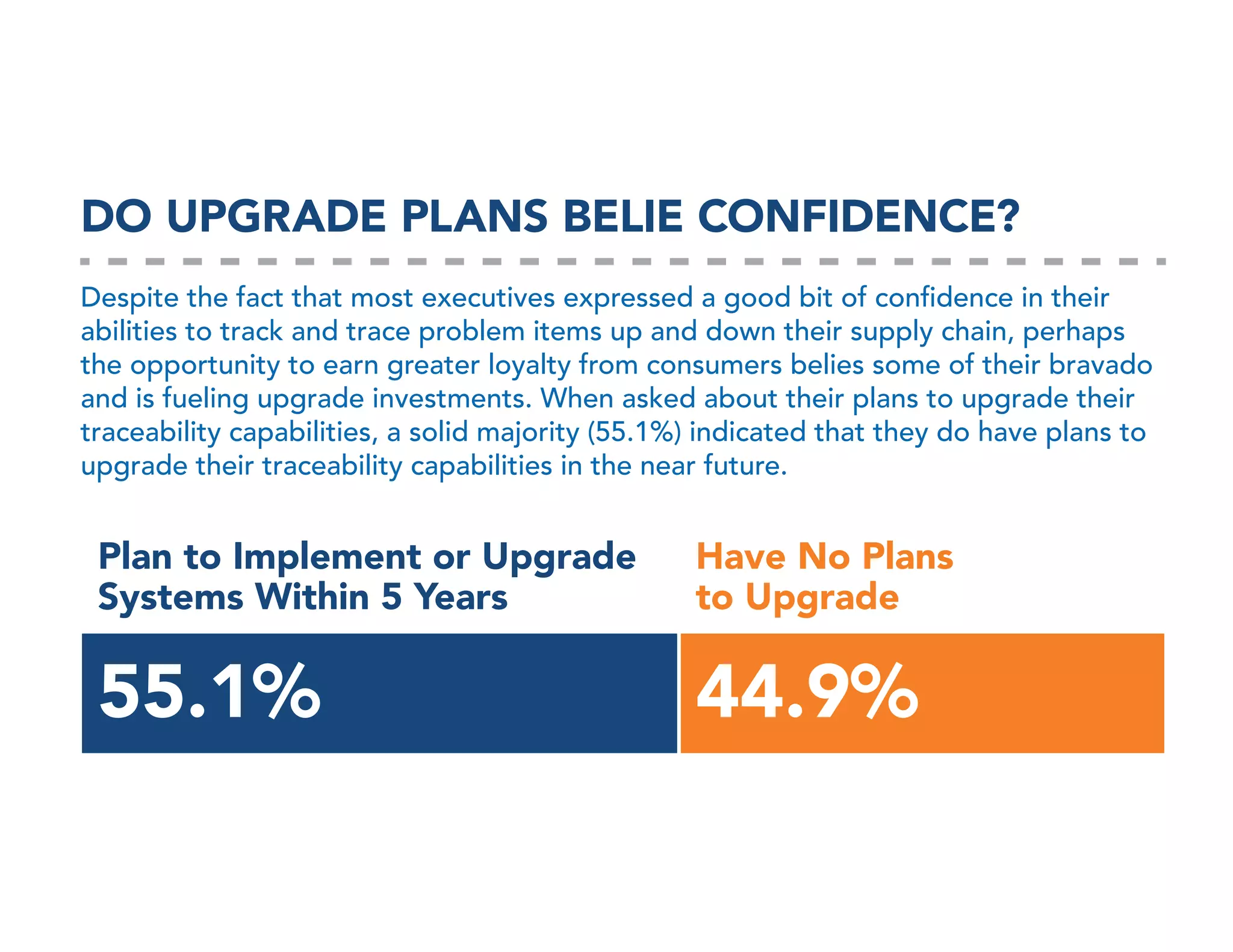

The document discusses the results of a survey about traceability challenges in supply chains. It finds that while many executives express confidence in being able to trace problems up and down the supply chain, nearly half of respondents said it would take days or weeks to execute a recall. Automation of trace processes is limited, and concerns around risks, costs, and regulatory compliance remain high. However, opportunities exist to improve traceability through technology upgrades and gain consumer loyalty by responsibly handling recalls.