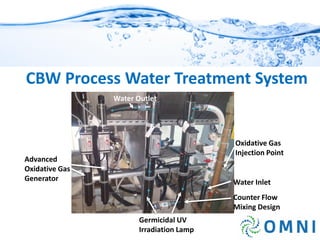

Omni Solutions provides water treatment systems that use advanced oxidation processes to purify water. Their CBW system uses counter flow mixing, an advanced oxidative gas generator, and UV irradiation lamps to reduce bacteria and other contaminants by 99.9% without chemicals. The system injects oxidative gas generated on-site and exposes the water to UV light to generate hydroxyl radicals that safely and effectively treat the water.

![HYDROXYL RADICALS

Names

IUPAC nameHydroxyl radical

Systematic IUPAC nameOxidanyl

[1]

(substitutive)

Hydridooxygen(•)

[1]

(additive)

Other namesHydroxy

Hydroxyl

λ

1

-Oxidanyl

Identifiers

CAS Number 3352-57-6

ChEBI CHEBI:29191

ChemSpider 138477

Gmelin Reference 105

Jmol 3D model Interactive image

KEGG C16844

PubChem 157350

InChI[show]

SMILES[show]

Properties

Chemical formula HO

Molar mass 17.01 g·mol

−1

Thermochemistry

Std molar

entropy (S

o

298)

183.71 J K

−1

mol

−1

Std enthalpy of

formation (ΔfH

o

298)

38.99 kJ mol

−1

Except where otherwise noted, data are given for materials in their standard state (at 25 °C

[77 °F], 100 kPa).

Infobox references](https://image.slidesharecdn.com/918d293d-a053-4fcd-bf25-8fcddbea3492-160912153401/85/OMNI-CBW-Product-Presentation-13-320.jpg)

![OZONE

Names

IUPAC nameTrioxygen

Identifiers

CAS Number 10028-15-6

ChEBI CHEBI:25812

ChemSpider 23208

EC Number 233–069–2

Gmelin Reference 1101

IUPHAR/BPS 6297

Jmol 3D model Interactive image

Interactive image

MeSH Ozone

PubChem 24823

RTECS number RS8225000

UNII 66H7ZZK23N

InChI[show]

SMILES[show]

Properties

Chemical formula O3

Molar mass 48.00 g·mol

−1

Appearance colorless to pale blue gas

[1]

Odor pungent

[1]

Density 2.144 mg cm

−3

(at 0 °C)

Melting point −192.2 °C; −313.9 °F; 81.0 K

Boiling point −112 °C; −170 °F; 161 K

Solubility in water 1.05 g L

−1

(at 0 °C)

Solubility very soluble in CCl4, sulfuric acid

Vapor pressure >1 atm (20 °C)

[1]

Refractive index(nD) 1.2226 (liquid), 1.00052 (gas, STP,

546 nm — note high dispersion)

[2]

Structure

Space group C2v

Coordination geometry Digonal

Molecular shape Dihedral

Hybridisation sp

2

for O1

Dipole moment 0.53 D](https://image.slidesharecdn.com/918d293d-a053-4fcd-bf25-8fcddbea3492-160912153401/85/OMNI-CBW-Product-Presentation-16-320.jpg)

![HYDROGEN PEROXIDE

Names

IUPAC namehydrogen peroxide

Other namesDioxidane

Oxidanyl

Identifiers

CAS Number 7722-84-1

ChEBI CHEBI:16240

ChEMBL ChEMBL71595

ChemSpider 763

EC Number 231-765-0

IUPHAR/BPS 2448

Jmol 3D model Interactive image

KEGG D00008

PubChem 784

RTECS number MX0900000 (>90% soln.)

MX0887000 (>30% soln.)

UNII BBX060AN9V

UN number 2015 (>60% soln.)

2014 (20–60% soln.)

2984 (8–20% soln.)

Properties

Chemical formula H2O2

Molar mass 34.0147 g/mol

Appearance Very light blue color; colorless in

solution

Odor slightly sharp

Density 1.11 g/cm

3

(20 °C, 30% (w/w)

solution )

[1]

1.450 g/cm

3

(20 °C, pure)

Melting point −0.43 °C (31.23 °F; 272.72 K)

Boiling point 150.2 °C (302.4 °F; 423.3 K)

(decomposes)

Solubility in water Miscible

Solubility soluble in ether, alcohol

insoluble in petroleum ether

Vapor pressure 5 mmHg (30 °C)

[2]

Acidity (pKa) 11.75

Refractive index(nD) 1.4061

Viscosity 1.245 cP (20 °C)

Dipole moment 2.26 D](https://image.slidesharecdn.com/918d293d-a053-4fcd-bf25-8fcddbea3492-160912153401/85/OMNI-CBW-Product-Presentation-22-320.jpg)