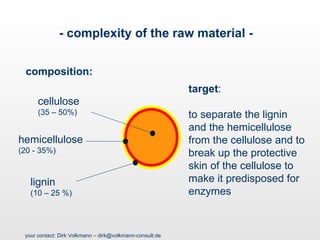

The document discusses technologies for converting lignocellulosic biomass into sugar for ethanol production. It describes various feedstocks and outlines two main technology pathways: acid hydrolysis and enzymatic processes. For acid hydrolysis it details different acid types and company approaches, while for enzymatic processes it outlines pretreatment options and key industry players. The document also reviews biomass synthesis gas technologies for producing ethanol from syngas.

![concentrated acid hydrolysis

hydrochloric acid :

biomass

Green Sugar Technology (GER)

Pre-sugar solution ( salts, amino acids, sugar [xyl, glc, ara, gal])

module 1

module 2 Main sugar solution (glc)

biomass

Hydrolysis wash water (glc)

pretreatment

HCl 32%ig

HCl 41%ig

Water

L ign in

HCl

module 3

module 4b module 4a

acid/sugar- water

acid recovery Acid absorbtion

Separation

w at er,

acet ic acid

sugar syrup sugar syrup

C5-rich C6-rich

(mainly xylose) (mainly Glucose)

source: www.green-sugar.eu

your contact: Dirk Volkmann – dirk@volkmann-consult.de](https://image.slidesharecdn.com/od81-124730023048-phpapp02/85/Cellulosic-Ethanol-Technologies-8-320.jpg)