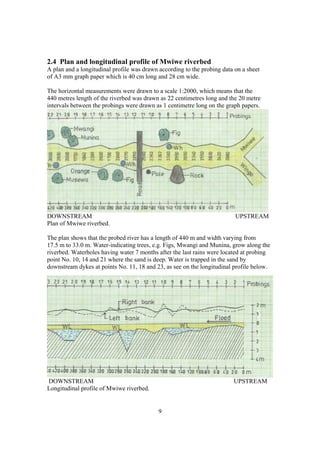

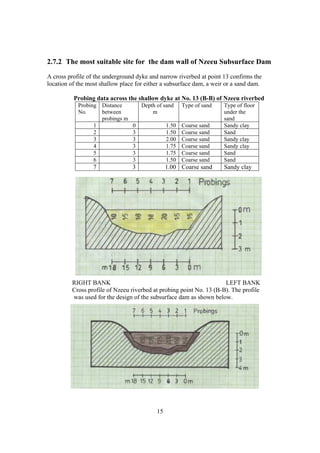

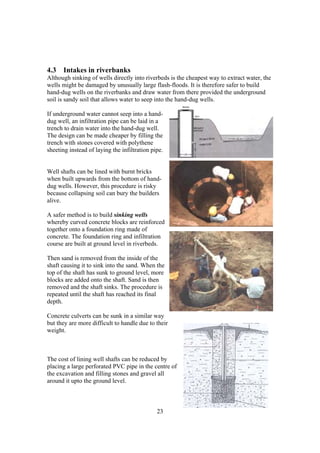

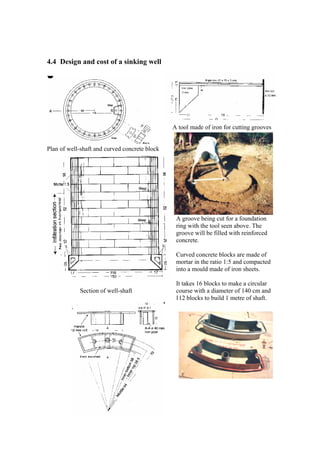

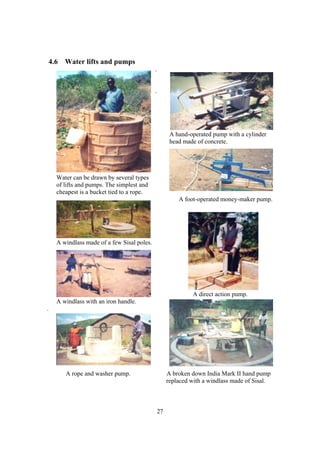

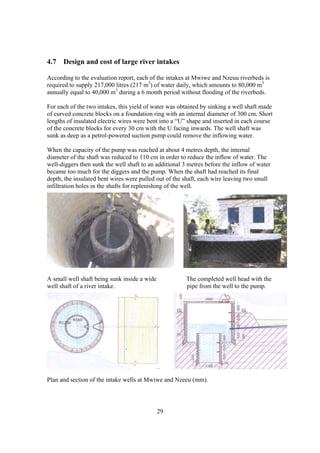

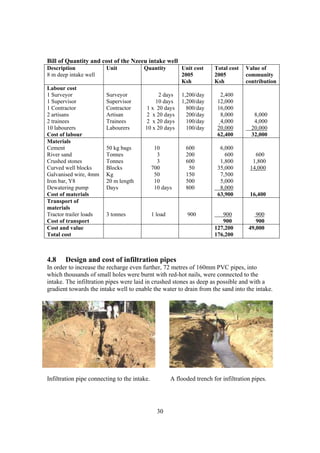

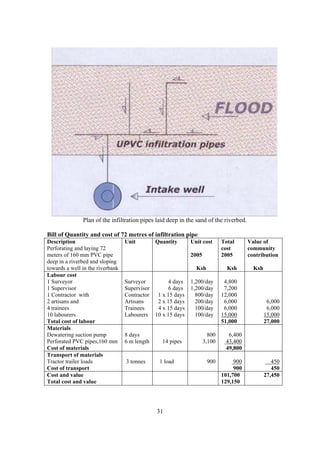

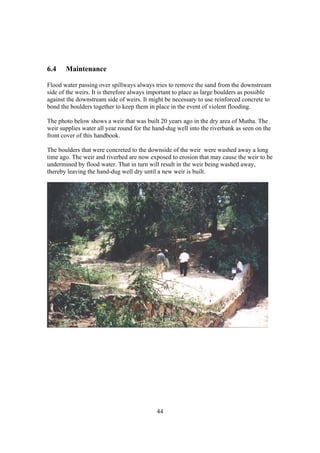

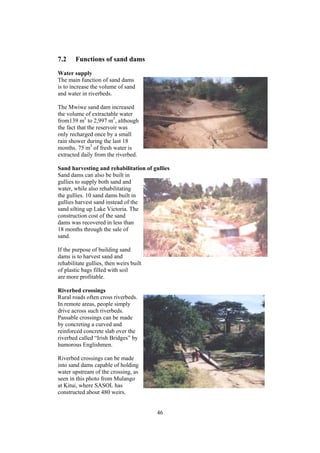

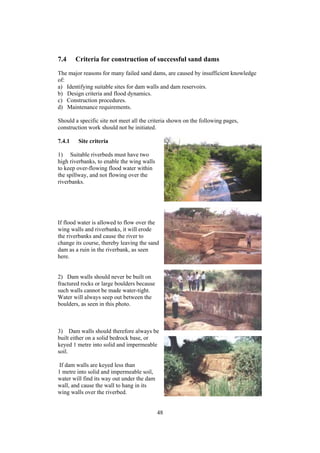

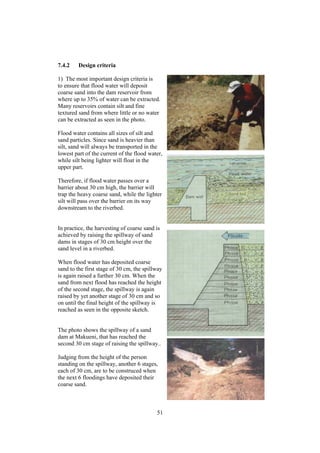

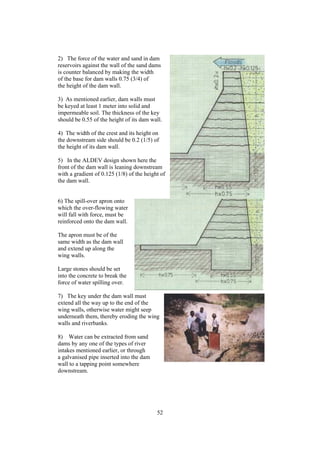

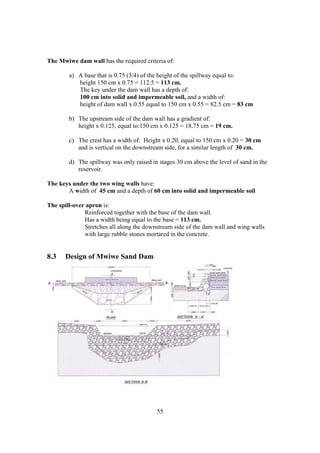

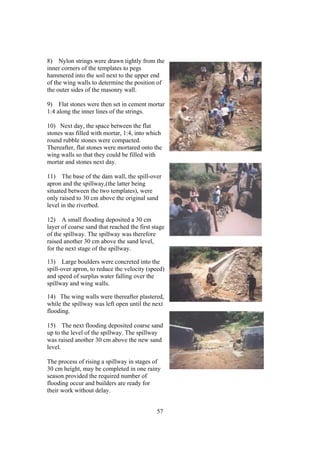

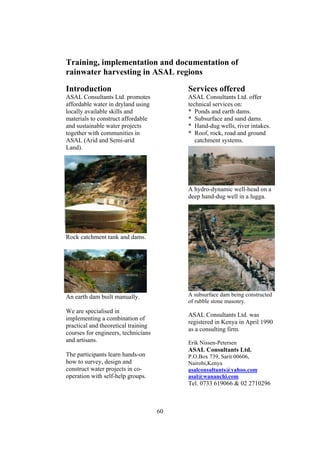

This document provides guidance on harnessing water from dry riverbeds through various techniques including hand-dug wells, subsurface dams, weirs, and sand dams. It begins by describing different types of riverbeds, how water is stored in sand, and existing water sources in riverbeds like unlined holes. The document emphasizes the importance of surveying riverbeds to identify suitable sites for intakes and dams before designing and implementing water projects. Overall, the document aims to provide practical information to help communities access reliable water sources from dry riverbeds.